SCS Blog

Recent SCS Blogs

Conformal Coatings Provide Critical Moisture Barriers

In today’s technology-driven world, exposure to moisture is one of the leading factors that can impact electronics’ ability to function as designed. When moisture comes in direct contact with the electronic circuits of a device, it can cause a short, resulting in device failure. Condensation inside of an enclosure, corrosive humidity in coastal regions, rain... Read More >>

Ultra-Lightweight Protection for Advanced Air Mobility

As aerospace technologies advance, world populations grow dense and people look to travel or to move products more quickly and safely, an influx of new aircraft is being developed. One type of aircraft currently in development is advanced air mobility (AAM). From carrying one to multiple passengers or transporting cargo, AAM aircraft range in both... Read More >>

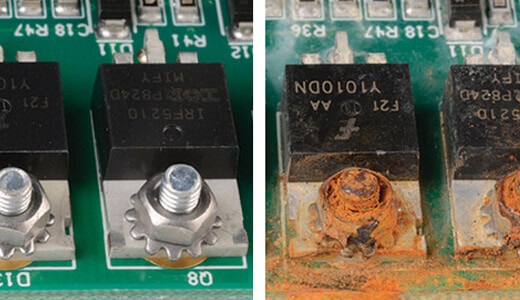

Corrosion Protection with Parylene

Corrosion is a natural occurrence that involves chemical and electrochemical reactions that slowly deteriorate materials or components in their operating environment. The resulting damage can pose risks and incur significant repair costs. Corroded electrical contacts in printed circuit boards (PCBs) and similar assemblies pose a serious risk, potentially causing life-threatening mechanical failures in aerospace, automotive,... Read More >>

Understanding Parylene Deposition

Parylene’s deposition process is unique among conformal coatings. Unlike conventional processes where materials begin as a liquid, solid Parylene undergoes a distinctive transformation. The Parylene coating equipment converts solid Parylene powder into vapor, which subsequently adheres to the substrate. Although this innovative four-step approach presents certain challenges, it also offers significant benefits. Sublimation In the... Read More >>

Ruggedizing Electronics with Parylene

Ruggedized products are strengthened by various processes to ensure better resistance and prolonged use in extremely harsh operating conditions. These conditions exist for aerospace/aeronautic, automotive, commercial off-the-shelf (COTS), medical and military products, which require reliable performance through a disparity of functional environments that include: Safeguarding printed circuit boards (PCBs) and similar electronic assemblies that power... Read More >>

Solvent Use in Parylene Deposition

Despite being well-versed in the different types of conformal coatings, many individuals mistakenly believe that the chemical vapor deposition (CVD) process for Parylene coatings involves the use of a solvent. This misconception is debunked below. Parylene Deposition Parylenes are polymers capable of providing resilient, dielectric, micron-thin conformal coatings for an exceptional variety of products and... Read More >>

Parylene Protects Stents

Biocompatible Parylene conformal coatings provide superior protection for medical stents. As an enabling technology, Parylene has been applied to medical devices of all types as a solution to problems stemming from surface microporosity and consequent biofluid corrosion after implant. Providing a reliable barrier to chemicals and moisture, Parylene’s static and dynamic coefficients of friction are... Read More >>

Protecting Solar Panel Electronics with Parylene

As with all renewable energy technologies, electronics play a crucial role in the operation of solar (photovoltaic) panels by facilitating the transformation, transmission and monitoring of the system. Unfortunately, system electronics are often delicate, making them the weakest link in the panel setup. Harnessing the sun’s energy to generate electricity, solar panels have demonstrated their... Read More >>

6 Conformal Coating Defects and How to Best Avoid Them

Conformal coatings, comprised of polymeric materials, serve the purpose of protecting circuitry, parts, and associated components. While their primary application is safeguarding printed circuit boards (PCBs) and electronic devices, these coatings have the versatility to be applied to a range of substrates such as metal, plastic, silicone, ceramics, glass and even paper. Conformal Coating Costs... Read More >>

Crevice Penetration of Parylene

Parylene provides a robust, dielectric, micron-thin conformal coating for a considerable range of electronic devices, most prominently printed circuit boards (PCBs). Parylene’s unique chemical vapor deposition (CVD) application method synthesizes in-process, depositing gaseous Parylene deep into a substrate’s surface. CVD occurs on a molecule-by-molecule basis, conforming to all underlying contours, regardless of shape or position, to the... Read More >>