SCS Blog

Recent SCS Blogs

Parylene vs Acrylic Conformal Coatings

Parylene and acrylic resins serve as conformal coatings, yet their similarities are limited. Due to their distinct properties, each possesses unique uses and capabilities. Application Acrylic conformal coatings, a type of liquid conformal coating, can be applied in four ways: by spray, dip, brush or robotics. The chosen method depends on several factors, such as... Read More >>

Parylene and Wearable Devices

Wearables are no longer an emerging technology — they are here. Whether a wearable is a medical device like an insulin pump, a smart watch or even a finely woven piece of smart fabric, they all have one basic fact in common. All of them contain technologies that need protection from the outside world, and... Read More >>

Benefits of Parylene Coatings for Electronics

Parylene conformal coatings are some of the best protection options available for printed circuit boards, multi-layer assemblies and other electronics. The coatings are applied through a vapor phase deposition (VPD) process that transforms the solid Parylene raw material, known as dimer, into a gas, enabling complete coverage of the substrate’s surface including deep penetration into... Read More >>

Properties of Acrylic Conformal Coating

Exceptionally user-friendly, liquid acrylic resin (AR) conformal coatings protect printed circuit boards (PCBs) and similar electronics from corrosion, dirt/dust, fungus, moisture and thermal shock. AR’s ease of application contributes to its status as the most frequently used conformal material. Liquid Application Methods for AR The primary means of AR liquid application are brush, dip (immersion)... Read More >>

Low Outgassing Conformal Coatings

Hermeticity and Outgassing In an ideal hermetic system that is under vacuum and completely sealed, unless gas is injected, entry of gasses from the surrounding environment is restricted. However, in reality hermetic systems can still have some leakage through their sealings and via outgassing of internal components. Outgassing is the desorption of gases/vapors from the... Read More >>

Differences between Parylene and Acrylic Conformal Coating

Parylene and acrylic conformal coatings represent two extremes of the types of compounds that can be used to coat printed circuit boards, sensors or an array other devices. While acrylic is popular and inexpensive, Parylene offers some of the best performance of any coating compound. Understanding AR Acrylic resin (AR) is the most commonly used... Read More >>

Review and Summary of Michael Osterman’s “Effectiveness of Conformal Coat to Prevent Corrosion of Terminals”

The article “Effectiveness of Conformal Coating in Preventing Terminal Corrosion” by author Michael Osterman was first released in the IPC Proceedings and later published online by Circuit Insight. Michael Osterman is associated with the Center for Advanced Life Cycle Engineering at the University of Maryland, located in College Park, MD. This article delves into the... Read More >>

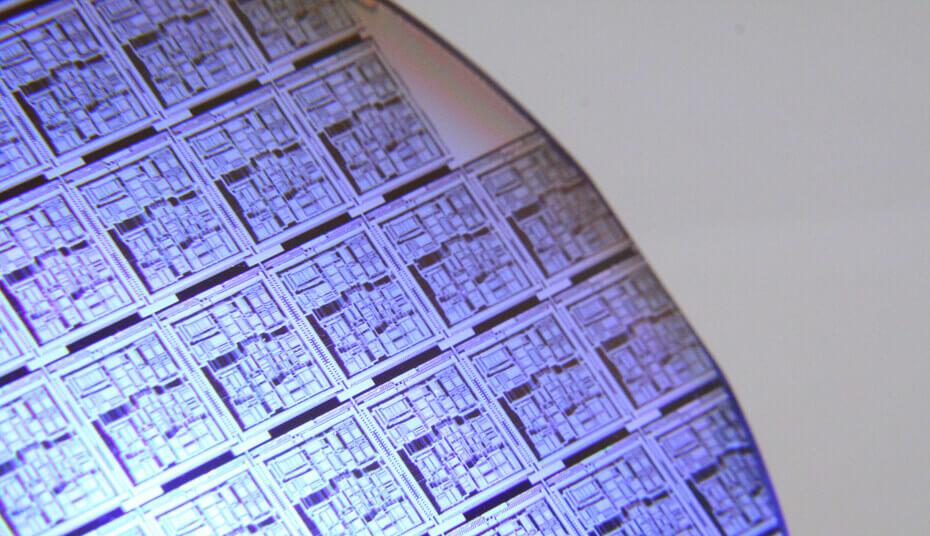

Printed Circuit Boards and Parylene

While Parylene can be applied as a uniform coating across a wide variety of applications, one of its most common uses is for protecting printed circuit boards (PCBs). Product engineers utilize Parylene because it offers a unique blend of capabilities. Thin and Complete Parylene is the only commonly used conformal coating that is deposited in... Read More >>

Benefits of Automotive Conformal Coatings

Silicone and Parylene coatings are among the best options on the market to protect automotive electronics and components. Silicone coatings are applied by dipping, brushing or spraying, and Parylene coatings are applied by chemical vapor-based deposition (CVD). Advantages of each coating are listed below. Advantages of silicone coatings for automotive electronics include: Impact and shock... Read More >>

Best Conformal Coating for Moisture and Chemical Protection

Conformal coatings safeguard printed circuit boards (PCBs) from performance malfunction caused by contact with elements within their operational environment, including moisture presence within the PCB, altering its thermo-mechanical properties and chemical incursion which can quickly corrode PCB components. In addition to mitigating these specific causes of PCB malfunction, conformal coatings also provide an overlying measure... Read More >>