Corporate

Technical Library

SCS Conformal Coatings

-

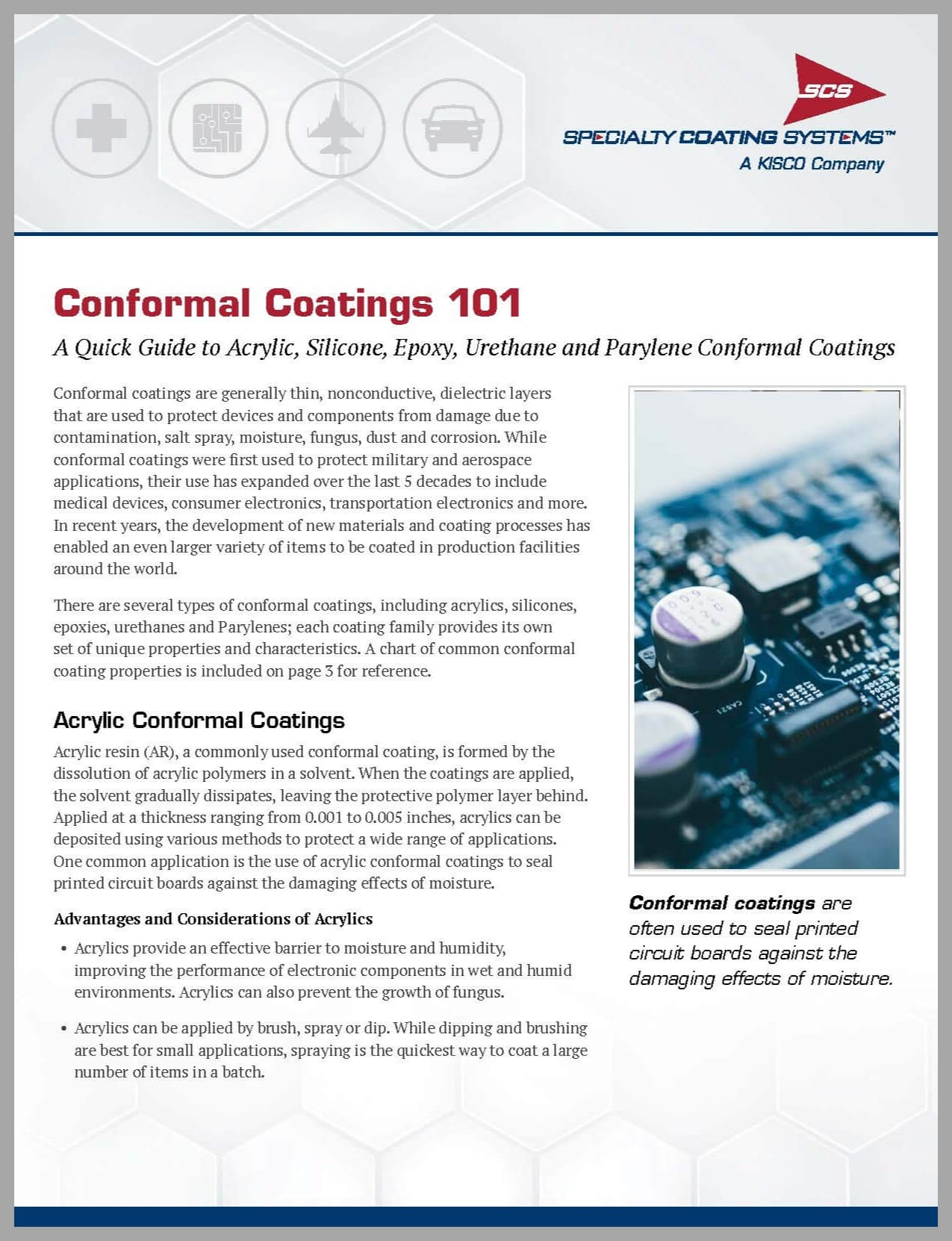

Conformal Coatings 101

Conformal coatings are generally thin, nonconductive, dielectric layers that are used to protect devices and components from contamination, moisture damage, temperature extremes and corrosion. There are several types of conformal coatings; each coating family provides its own set of unique properties and characteristics.

-

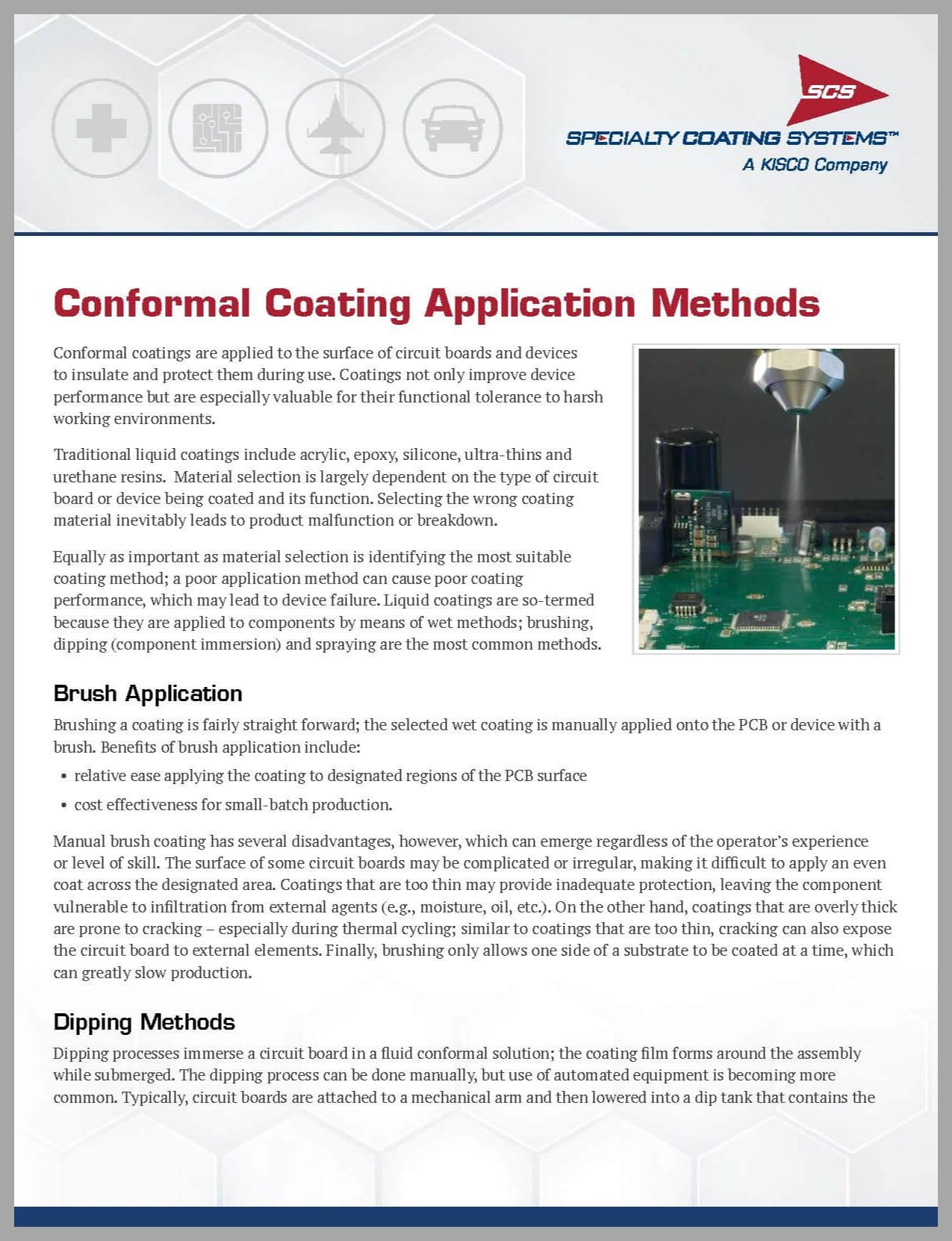

Conformal Coating Application Methods

Conformal coatings are applied to the surface of circuit boards and devices to insulate and protect them during use. Wet processes are to apply liquid coatings include brushing, dipping (component immersion) and spraying.

SCS Parylene Coatings

-

SCS Parylene Properties

Parylene is the generic name for members of a unique polymer series. The electrical, barrier, mechanical, thermal, optical, biocompatibility and other properties of SCS Parylenes N, C, D and Parylene HT® are discussed herein.

-

SCS Medical Coatings

Conformal coatings provide the vital protection needed for life-saving medical devices and ensure they perform reliably. SCS coatings offer medical devices a host of beneficial properties, including biocompatibility and biostability, excellent moisture and chemical barrier, micro-encapsulation and dry-film lubricity.

-

SCS Electronics Coatings

No matter the end use, electronic components must meet a complex and exacting set of specifications to ensure reliability and a trouble-free life. SCS coatings offer exceptional properties for electronic component protection.

-

SCS Automotive Coatings

Conformal coatings provide protection that today’s competitive transportation market demands, enabling smaller, more reliable, longer-lasting electronic packages and components.

-

SCS Aerospace & Defense Coatings

From electronic devices within defense aircraft, missile and ground systems to components that must operate in the depths of space, SCS conformal coatings provide reliable protection to ensure long, trouble-free life.

-

SCS LED Coatings

To ensure long-performance life, LEDs must be protected to operate reliably amidst extreme conditions. Ultra-thin and optically-clear SCS Parylene conformal coatings provide the protection necessary to sustain longer life.

-

Parylene Coatings for Elastomeric Components

Seals, O-rings, gaskets, stoppers and plungers are just a few of the elastomeric components that benefit from the properties that Parylene coatings offer.

SCS Equipment Lines

PARYLENE DEPOSITION SYSTEMS AND RAW MATERIALS

-

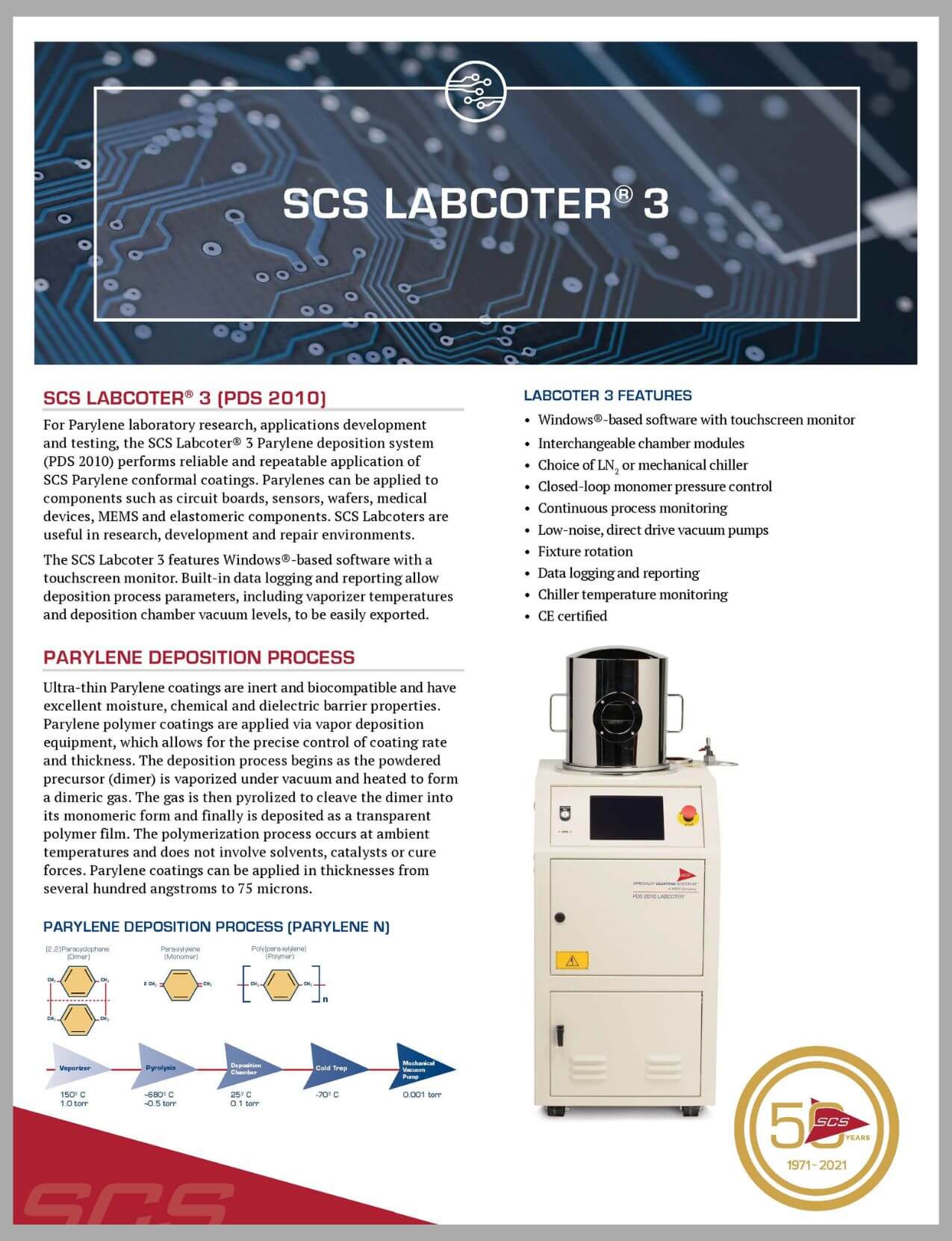

SCS 2010 LABCOTER® 3

For Parylene laboratory research, applications development and testing, the SCS Labcoter® 3 Parylene Deposition System performs reliable and repeatable application of SCS Parylene conformal coatings.

-

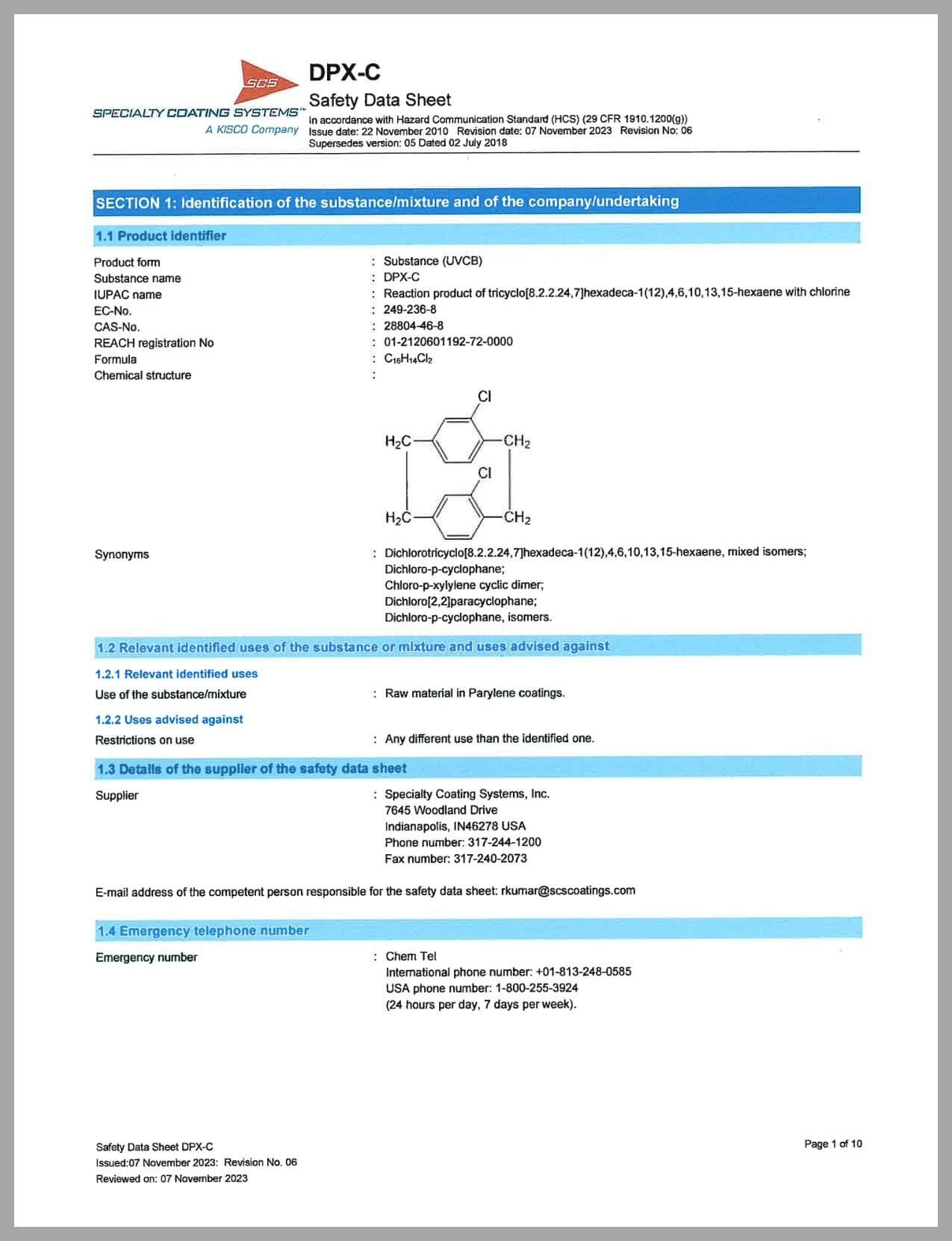

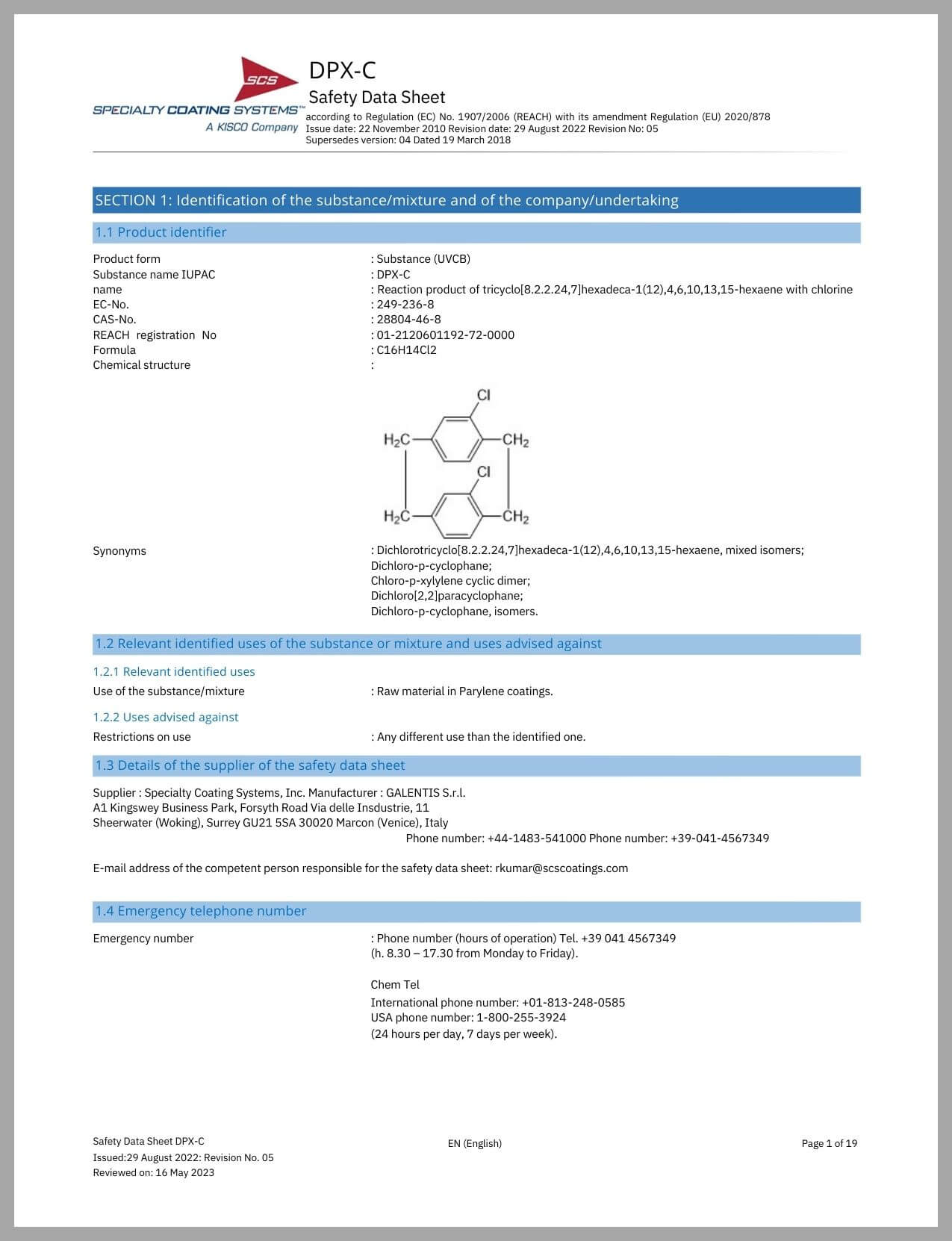

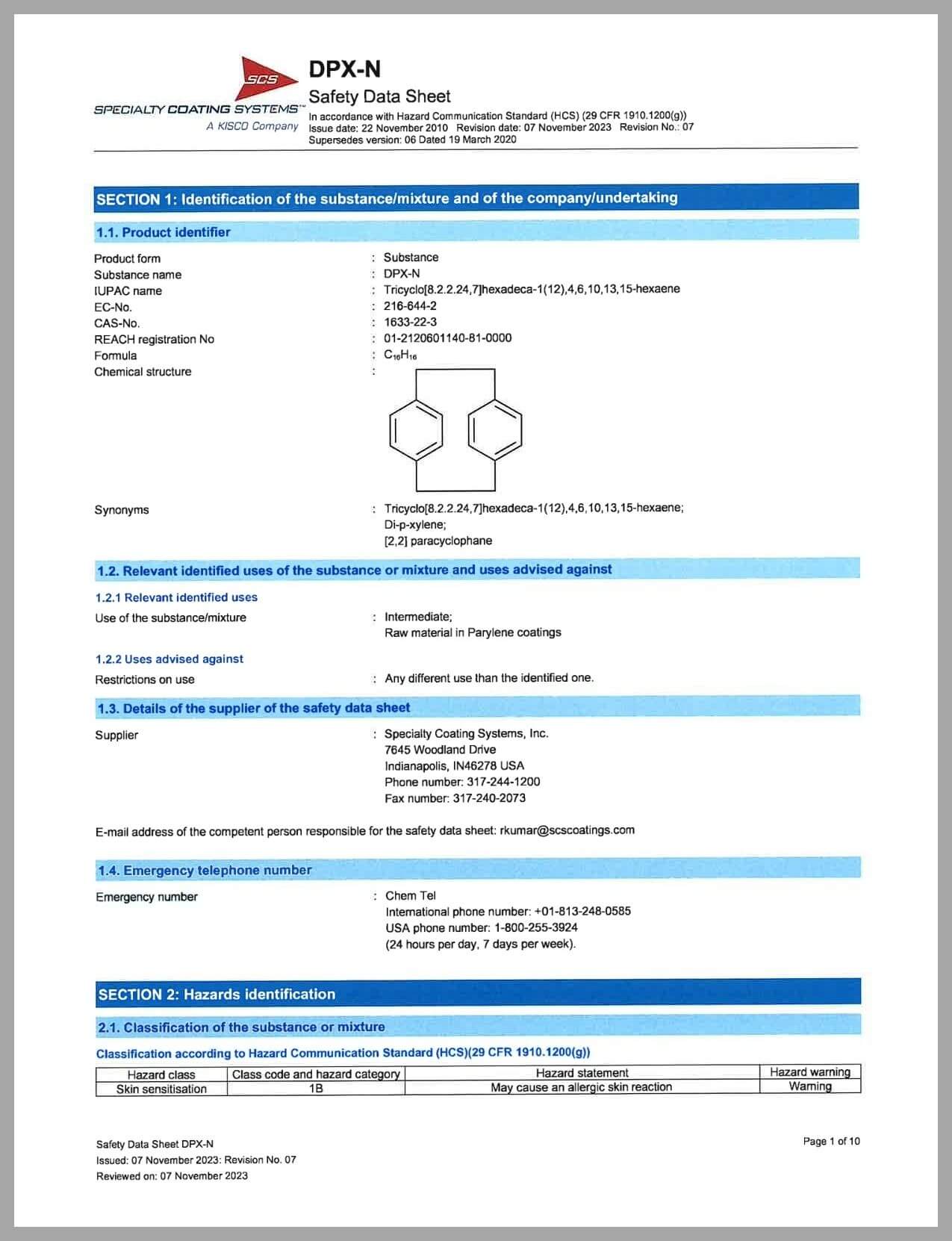

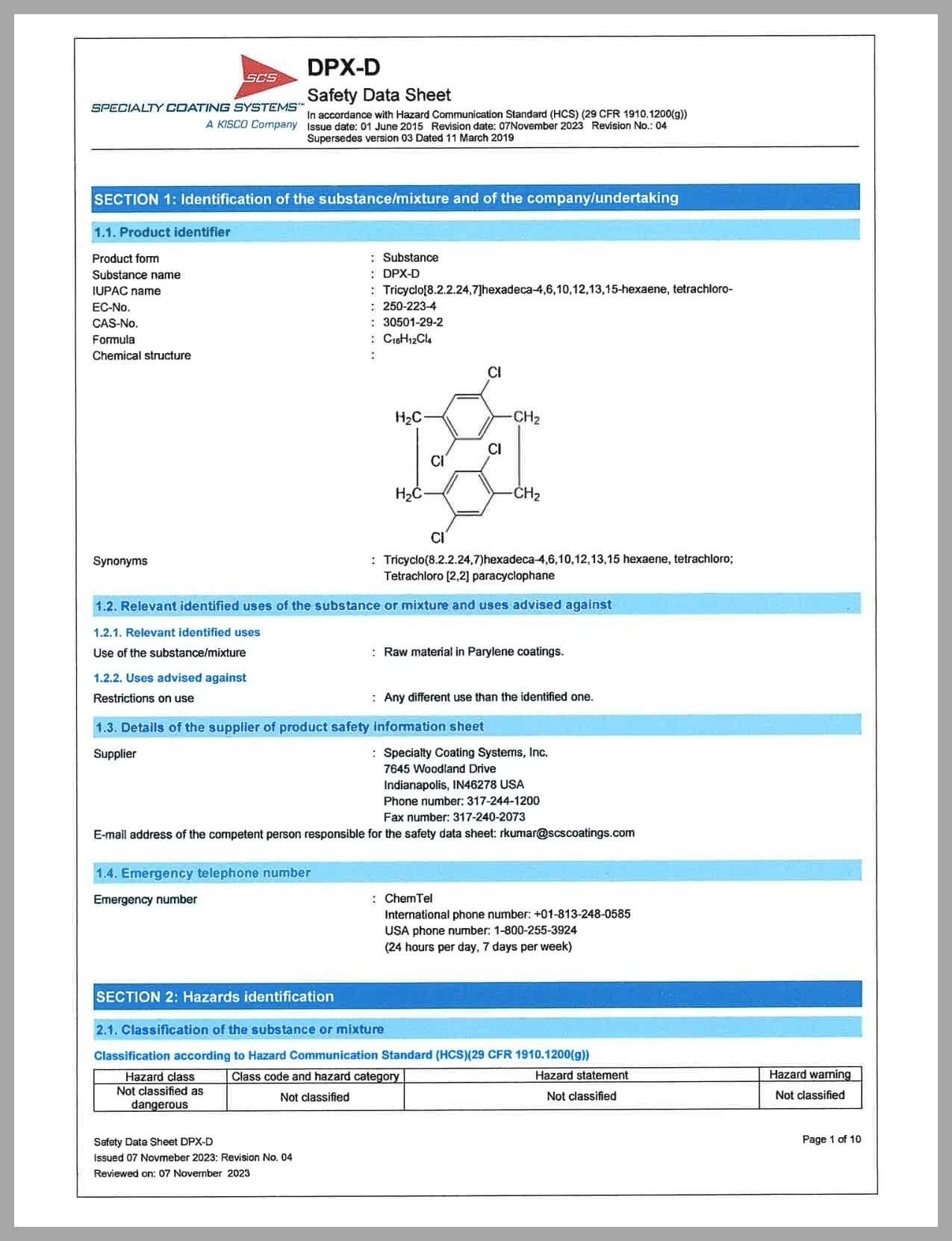

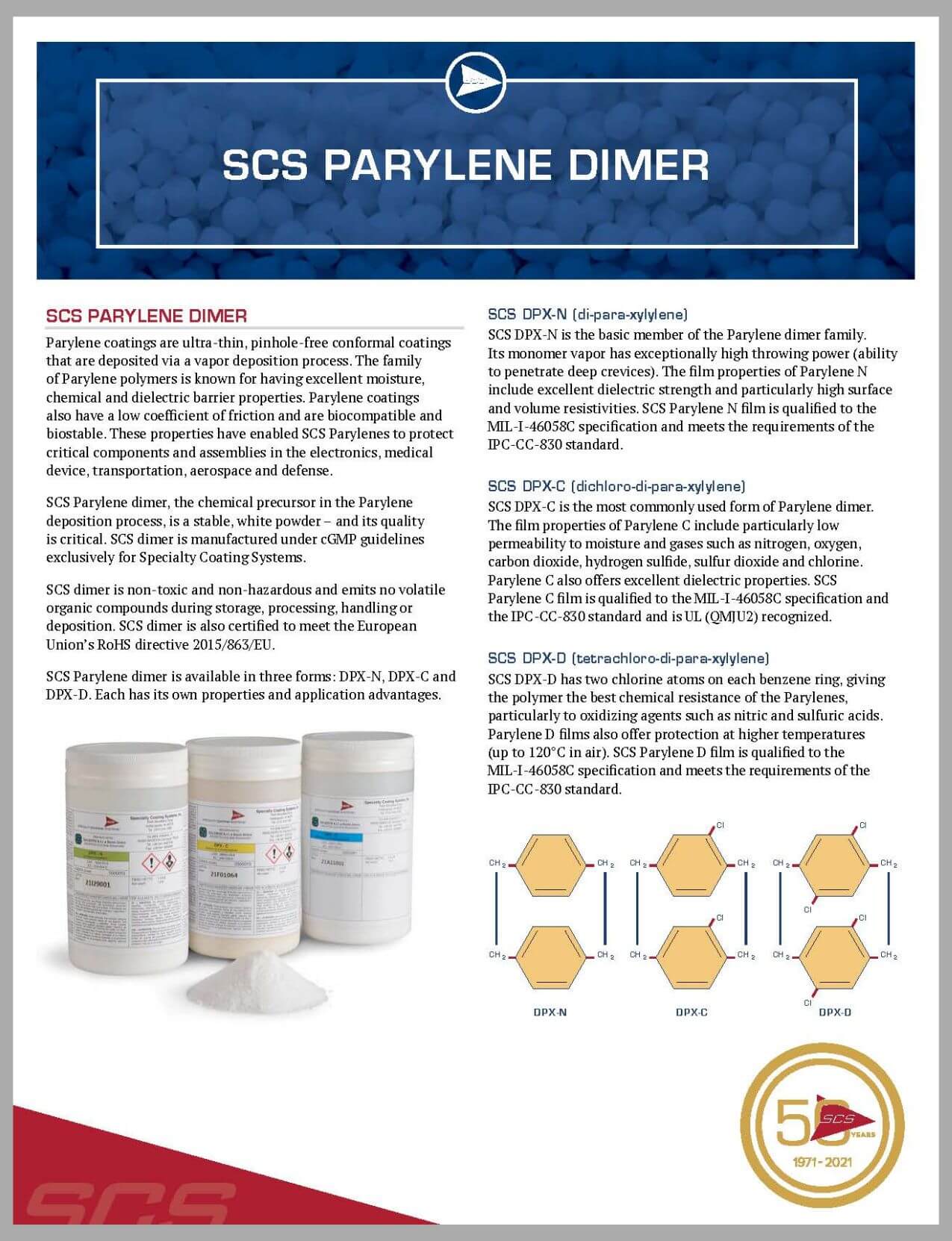

SCS Parylene Dimer

SCS Parylene dimer, the chemical precursor in the Parylene deposition process, is a stable, white powder – and its quality is critical. SCS dimer is manufactured under cGMP guidelines exclusively for Specialty Coating Systems.

SPIN COATING SYSTEMS & ACCESSORIES

-

G3 Spin Coater and Multi-Dispense Series

The SCS G3 Spin Coater series sets the standard in operating precision and programming flexibility, with a high level of rotation accuracy and repeatability, along with precise acceleration and deceleration control.

-

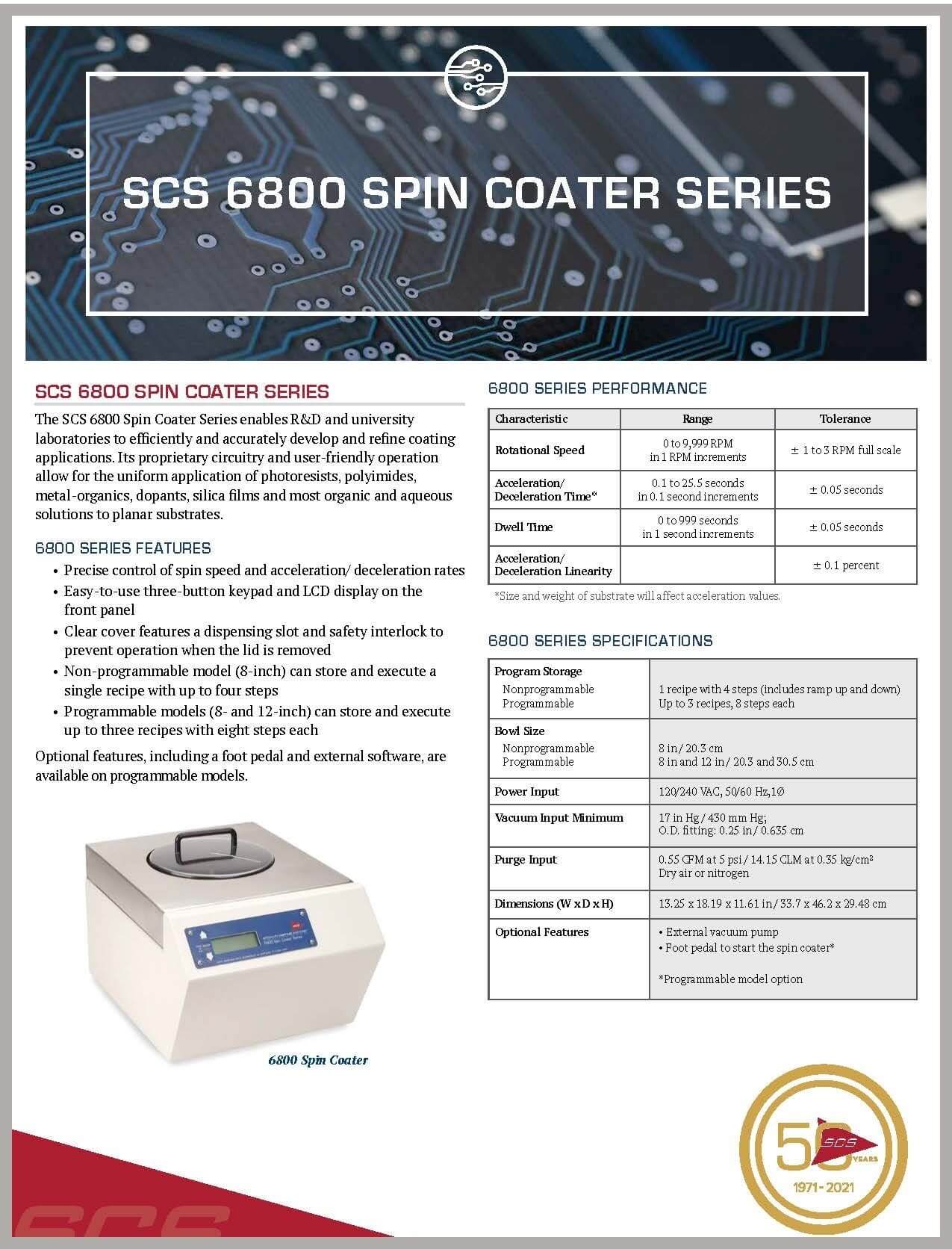

6800 Spin Coater Series

The SCS 6800 Spin Coater Series enables R&D and university laboratories to efficiently and accurately develop and refine coating applications.

DIP COATING SYSTEMS

-

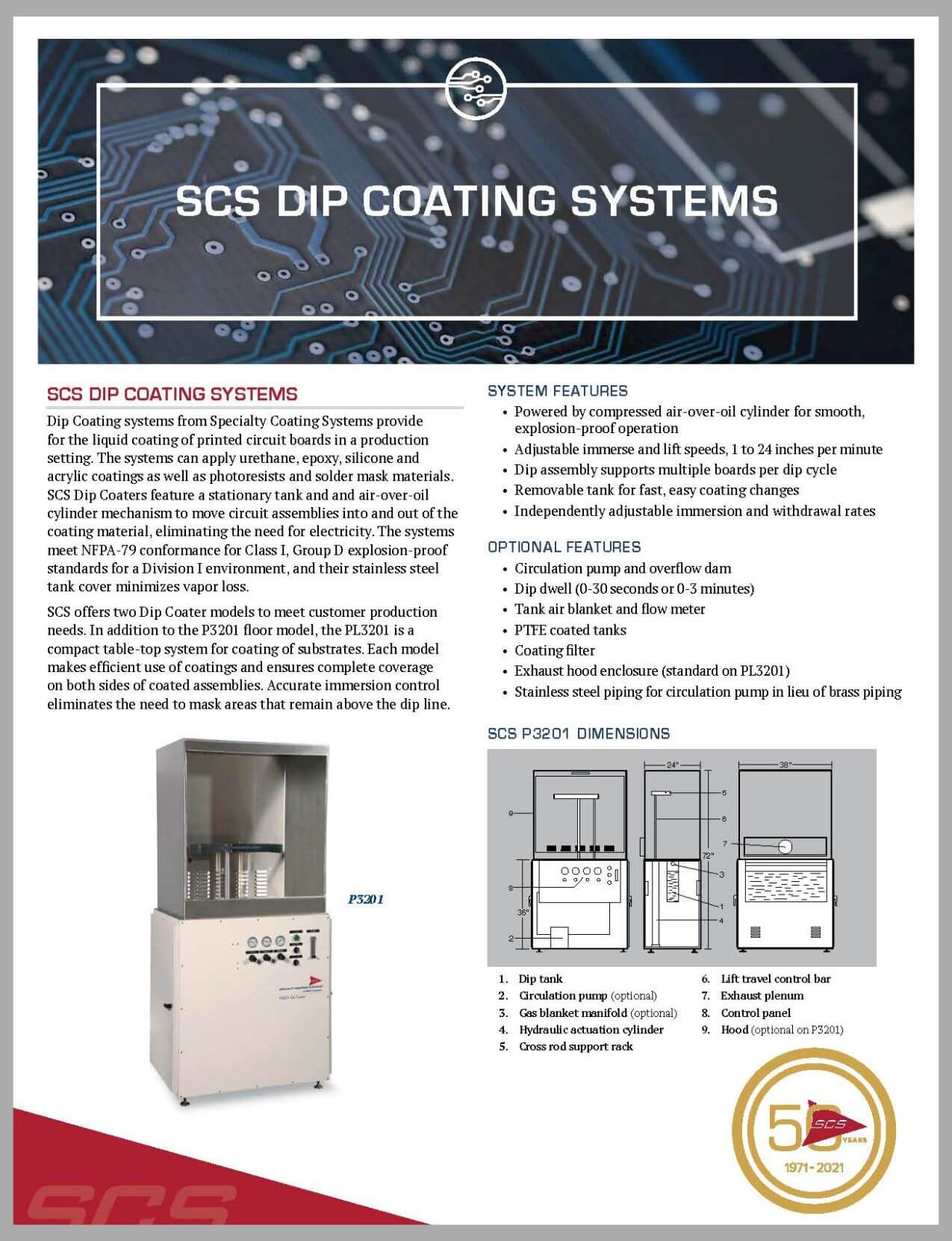

SCS Dip Coating Systems

SCS Dip Coating Systems provide for the liquid coating of printed circuit boards in production or laboratory settings. The systems can apply urethane, epoxy, silicone and acrylic coatings as well as photoresists and solder mask materials.

SPRAY, DISPENSE, AND POTTING SYSTEMS

-

SCS PrecisionCoat VI

The SCS PrecisionCoat VI provides more than a dependable layer of protection, it’s a total system solution that ensures accuracy, repeatability and high throughput for a wide range of automated material applications.

-

SCS PrecisionCoat BT

The SCS PrecisionCoat BT provides accuracy, reliability and flexibility for companies looking to automate or expand their coating and dispensing capabilities.

CURING SYSTEMS

-

SCS Precision UVC

The SCS Precision UVC provides robust, reliable UV curing capabilities for any production line.

-

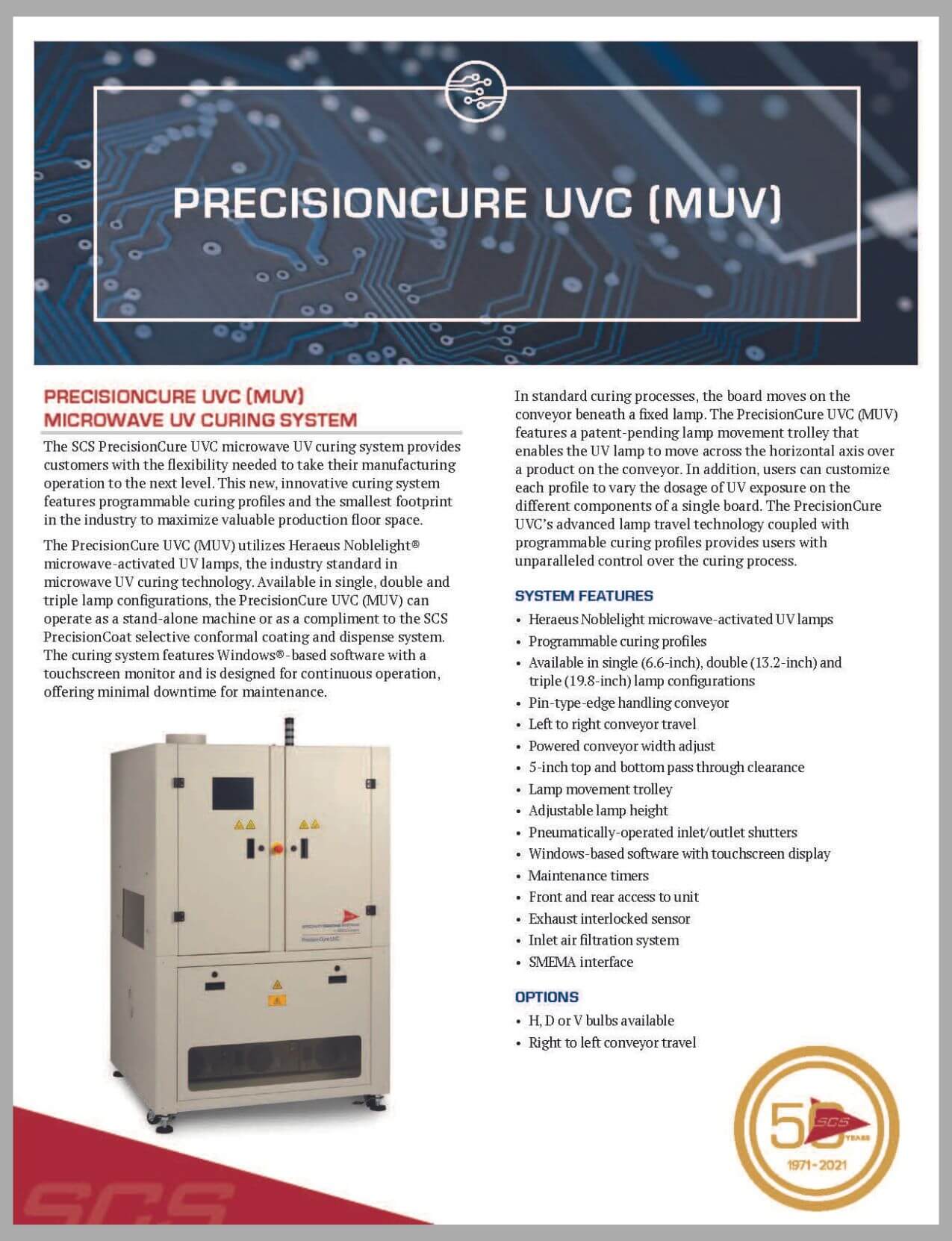

SCS PrecisionCure UVC (MUV)

The SCS PrecisionCure UVC (MUV) provides customers with unmatched flexibility. This new, innovative curing system features programmable curing profiles and the smallest footprint in the industry to maximize valuable production floor space.

-

PrecisionCure TC (IR)

The SCS PrecisionCure TC infrared radiation (IR) thermal curing system provides customers with the reliability and efficiency needed throughout the curing process.

-

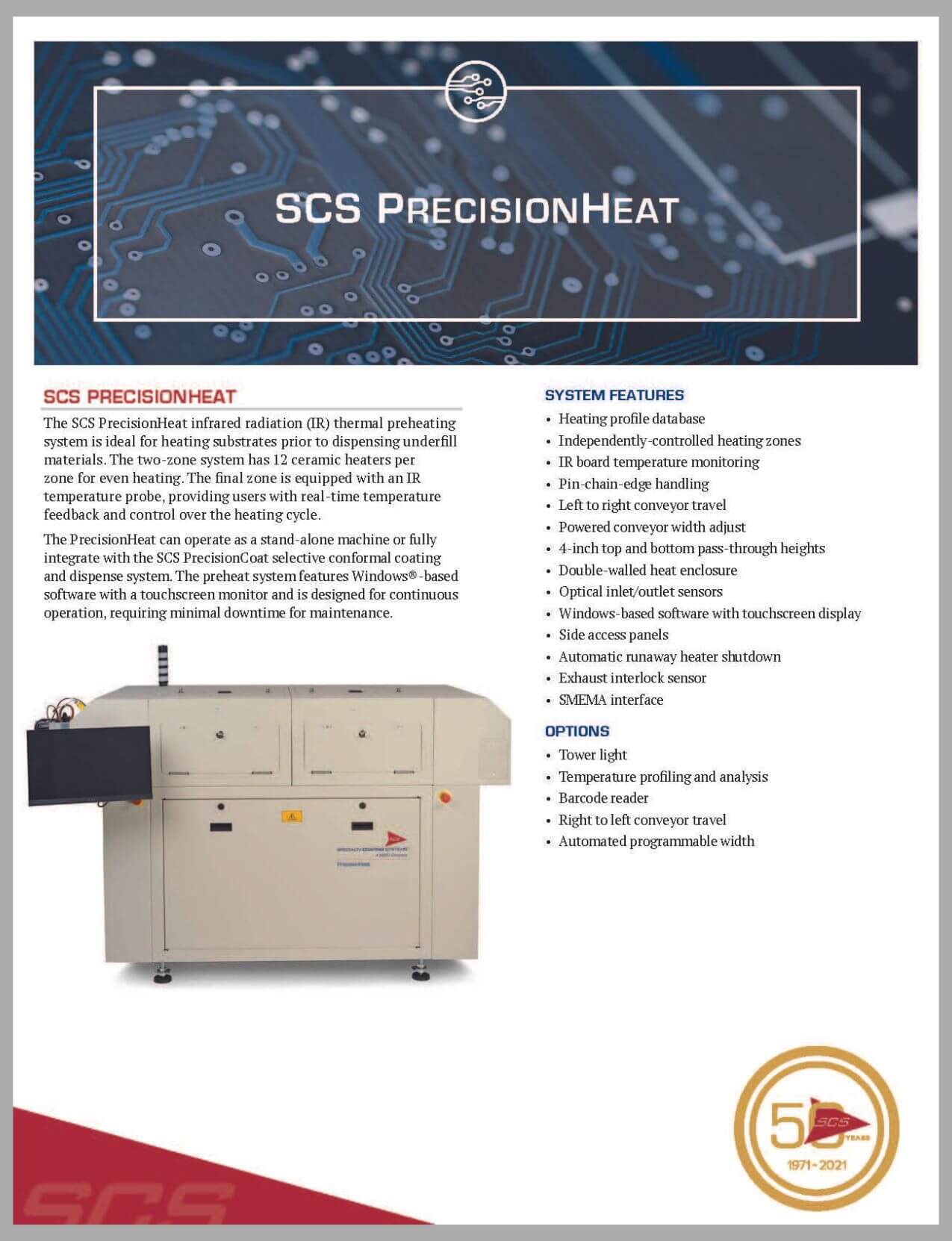

SCS PrecisionHeat

The SCS PrecisionHeat infrared radiation (IR) thermal preheating system is ideal for heating substrates prior to dispensing underfill materials.

CONVEYOR SYSTEMS

-

SCS PrecisionAdvance

The SCS PrecisionAdvance conveyor provides exceptional product handling and efficient step integration, which are often required for conformal coating and dispensing processes.

IONIC CONTAMINATION TEST SYSTEMS

-

SCS Ionograph® Series

The SCS Ionograph® series is designed for fast and accurate ionic contamination cleanliness testing. SCS offers a full range of capacity and control to meet the needs of any lab or manufacturer.

-

SCS Omegameter SMD 650

The SCS Omegameter SMD 650, the long-time industry standard for ionic testing utilizing “static test” methodology, is designed to perform cleanliness testing on printed circuits and assemblies.

Technical Papers

PARYLENE – GENERAL

-

Solvent Resistance of the Parylenes

Study reviews the effects of a wide variety of organic solvents on Parylenes N, C and D.

-

Controlling Parylene Process Quality

This paper identifies and describes quality issues related to use of Parylene vacuum-deposited conformal coating in the protection of electronic components and assemblies.

PARYLENE – MEDICAL

-

Advances in Adhesion Solutions for Medical Applications

As electronic devices become ever smaller, their performance in many different types of operating environments has led many device packaging companies into the world of conformal coatings. Adhesion of such coatings to the intended substrate surfaces is one of the most important features of a coating’s effectiveness.

-

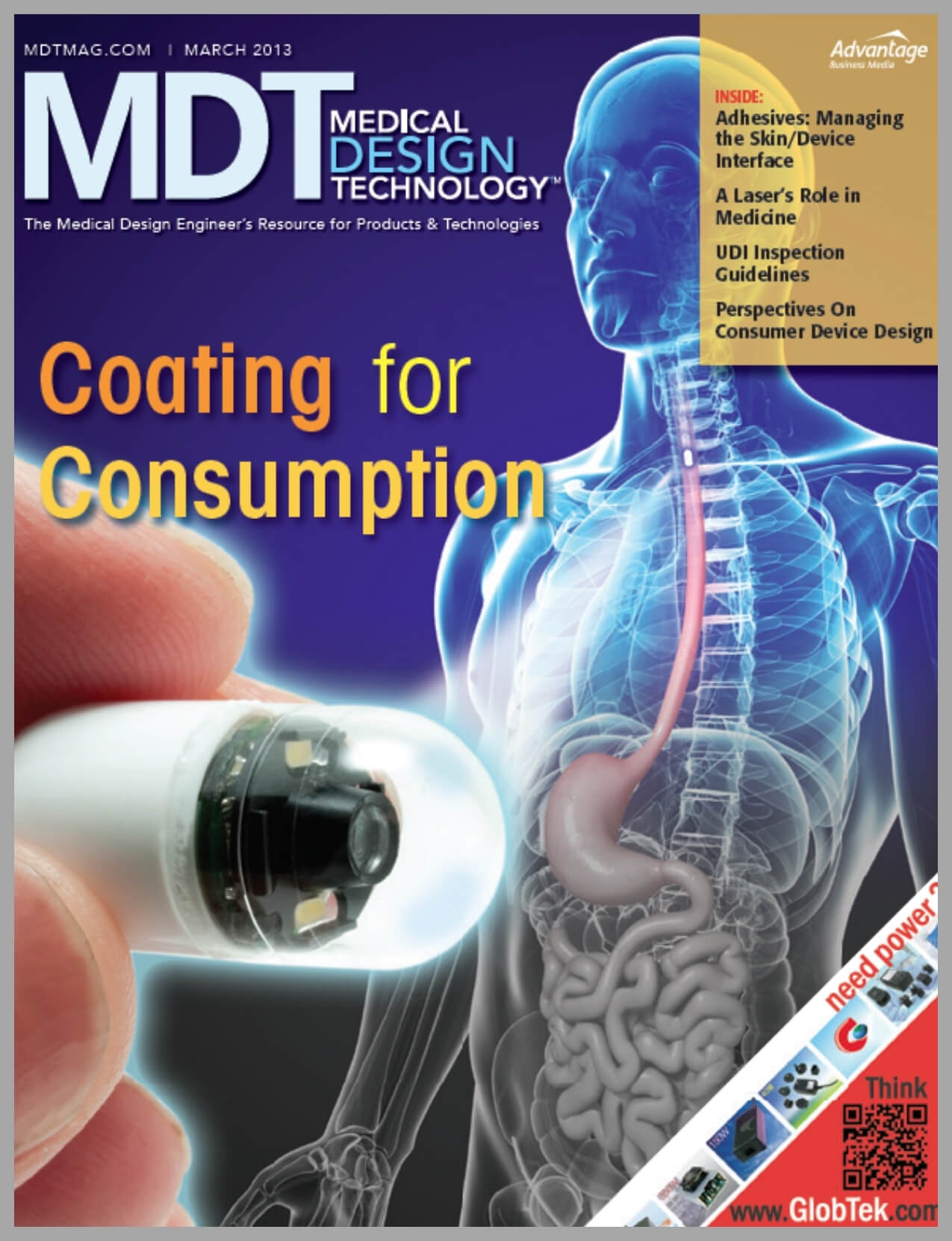

Coating for Consumption

Ingestible medical devices offer a convenient, non-invasive method of delivering therapeutics, enabling diagnostic procedures and performing imaging tasks. Ensuring that the sensitive electronics within the device are protected is a challenge. This article will highlight a technology that is being used to ensure such protection is provided.

-

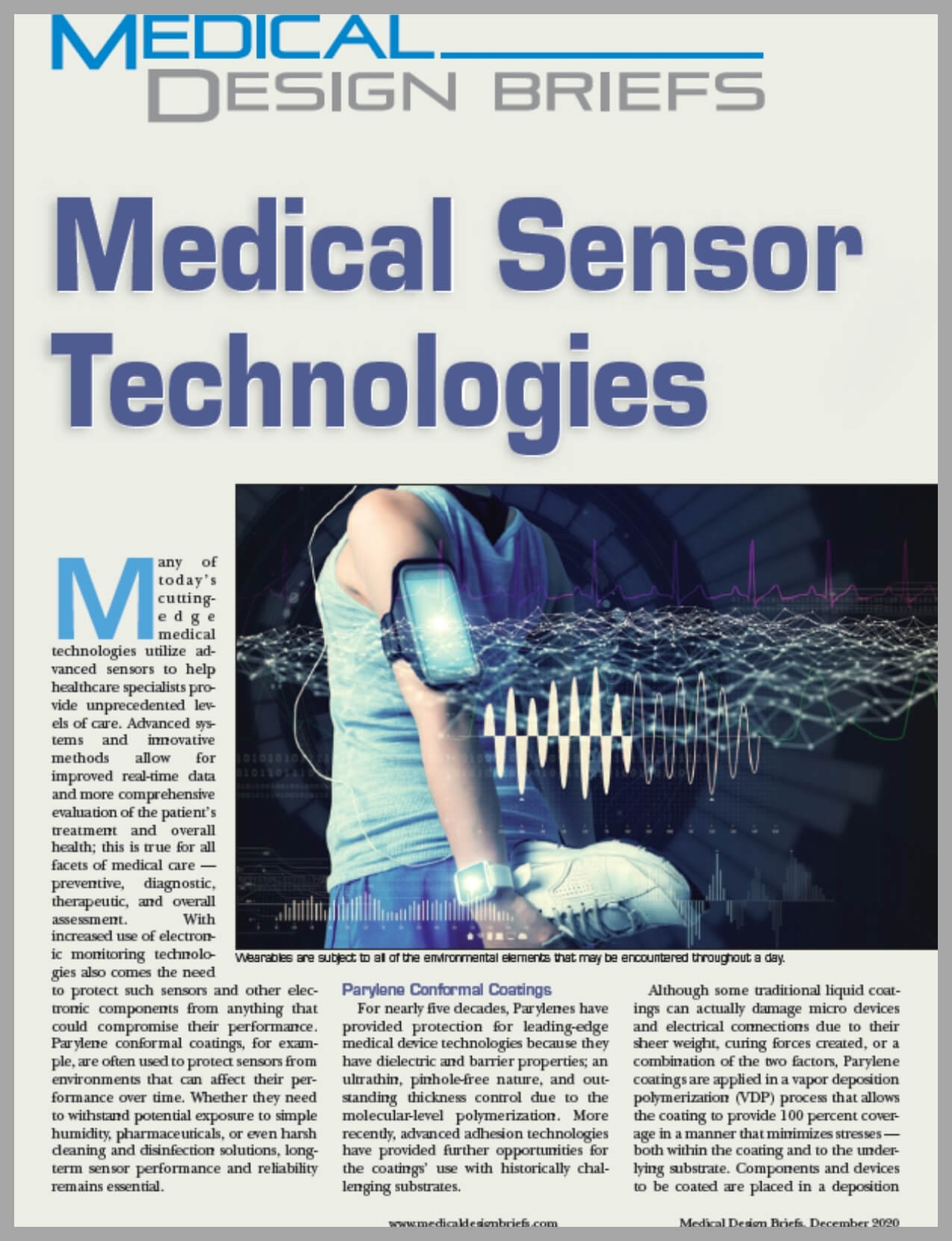

Medical Sensor Technologies

Many of today’s cutting-edge medical technologies utilize advanced sensors to help healthcare specialists provide unprecedented levels of care. The increased use of electronic monitoring technologies necessitates the need to protect such sensors and other electronic components from anything that could compromise their performance. This article will highlight Parylene’s role in protecting advanced medical sensor technologies.

-

Protecting Inhalation Drug Delivery with Parylene Conformal Coatings

This article describes applications of Parylene coatings as protective barrier coatings in inhalable drug delivery devices, and the detailed characteristics of Parylene which make it particularly suited to these applications.

-

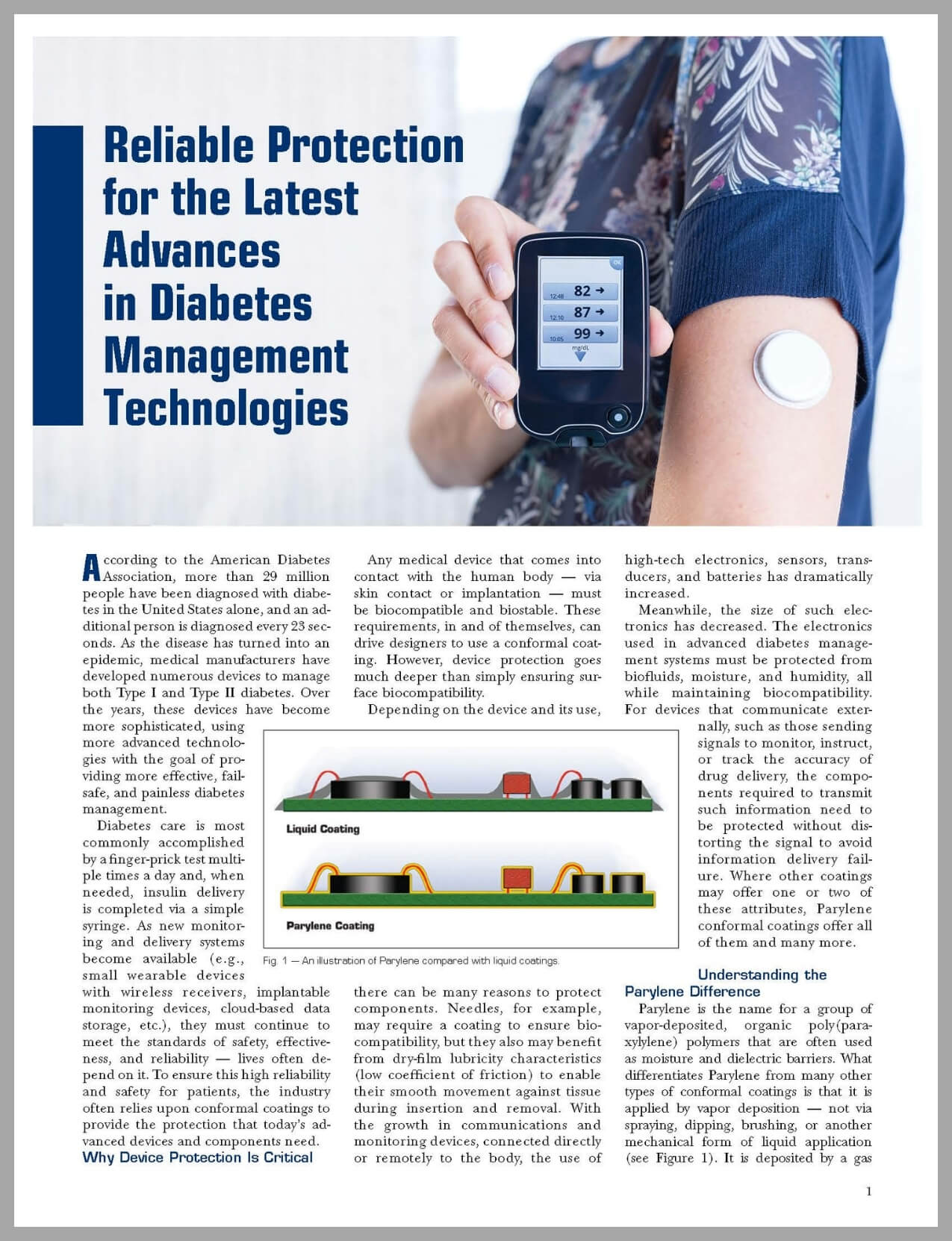

Reliable Protection for the Latest Advances in Diabetes Management Technologies

Diabetes care is most commonly accomplished by a finger-prick test multiple times a day and, when needed, insulin delivery is completed via a simple syringe. As new monitoring and delivery systems become available, they must continue to meet the standards of safety, effectiveness and reliability — lives often depend on it. To ensure this high reliability and safety for patients, the industry often relies upon conformal coatings to provide the protection that today’s advanced devices and components need.

PARYLENE – ELECTRONICS

-

Protecting Downhole and Platform Electronics

Oil companies must focus on cost savings to be profitable. A number of electronics used for the exploration, drilling, processing, and delivery of oil and gas operate in some of the harshest environments ever seen.

-

Parylene as a Suppressant for Tin Whiskers Growth on Printed Circuit Boards

With the implementation of RoHS directives, pure tin plating is replacing lead in the tin-alloy used in the printed circuit boards and other worldwide electronics. Although use of tin provides a safer environment for electronic manufacturers and helps meet the regulatory requirements, it is known to form tin whiskers, odd shape eruption and dendrites that cause printed circuit boards or devices to fail.

-

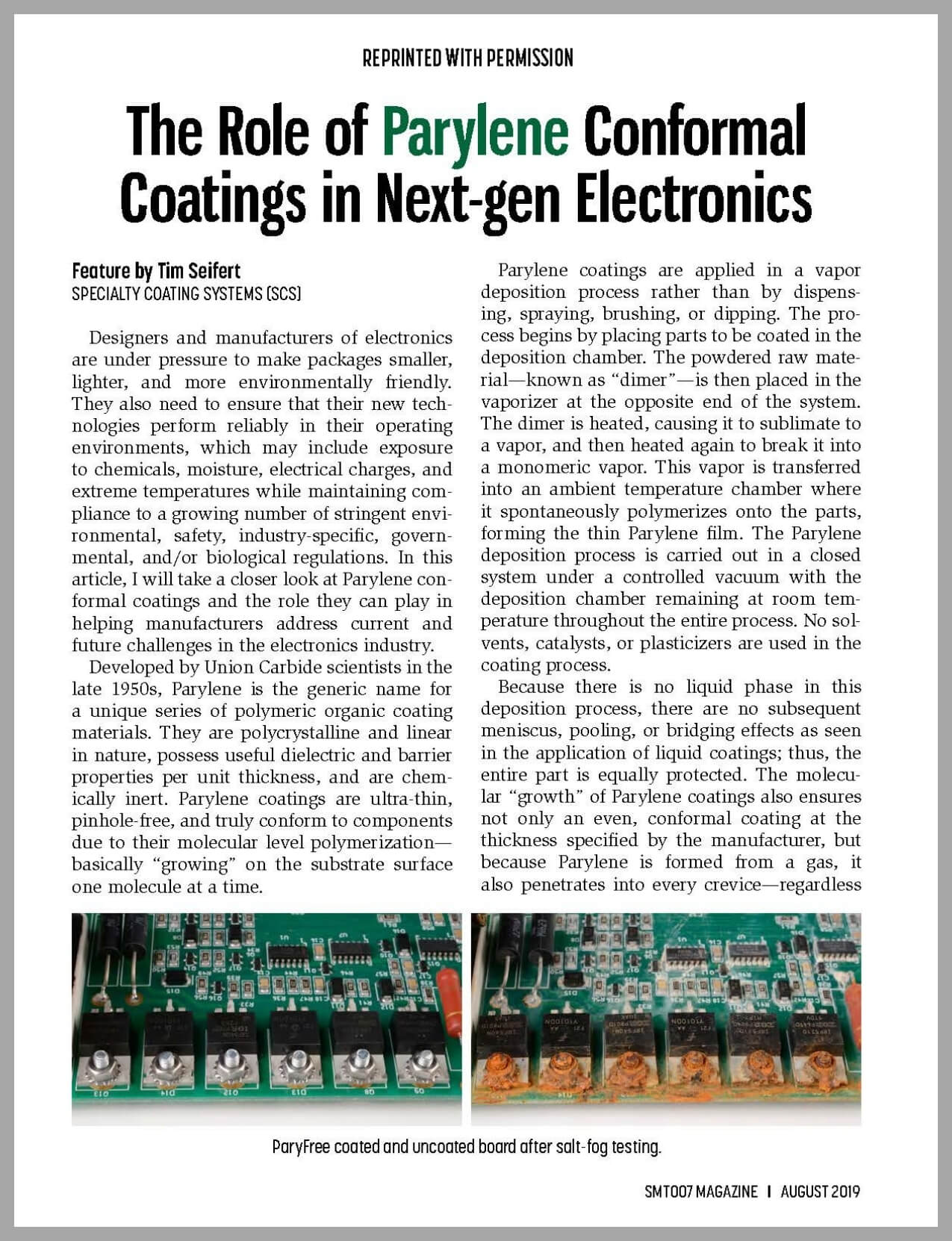

The Role of Parylene Conformal Coatings in Next-Gen Electronics

Designers and manufacturers of electronics are under pressure to make packages smaller, lighter and more environmentally friendly. They also need to ensure that new technologies perform reliably in their operating environments while maintaining compliance to a growing number of stringent regulations. This article will take a closer look at Parylene conformal coatings and the role they can play in helping manufacturers address current and future challenges in the electronics industry.

-

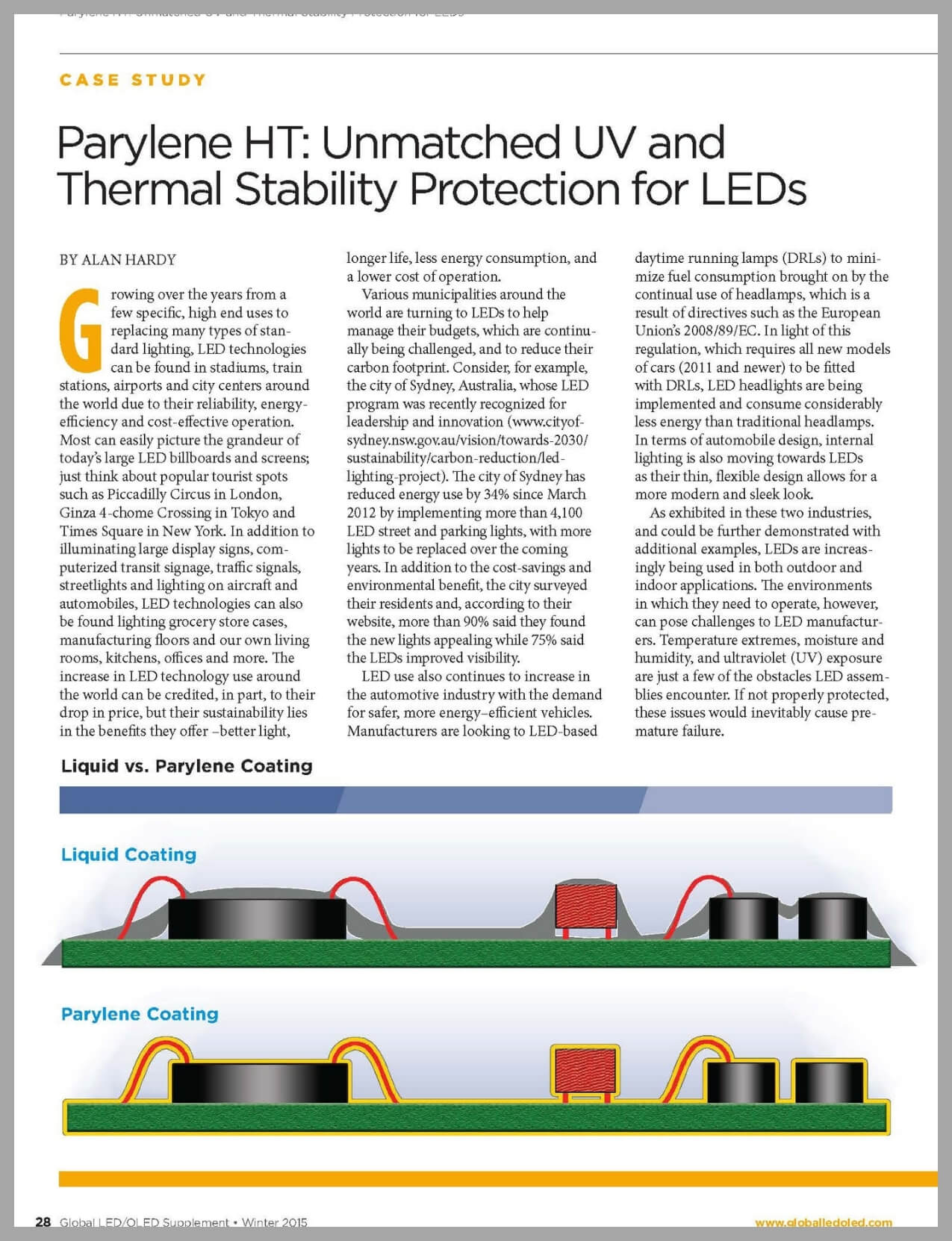

Parylene HT: Unmatched UV and Thermal Stability Protection for LEDs

LEDs are increasingly being used in both outdoor and indoor applications. The environments in which they need to operate, however, can pose challenges to LED manufacturers. This article will look at how Parylene coatings – more specifically, Parylene HT® – can benefit LED applications that require protection from moisture and humidity, high temperatures and/or UV exposure.

PARYLENE APPLICATIONS – AUTOMOTIVE

-

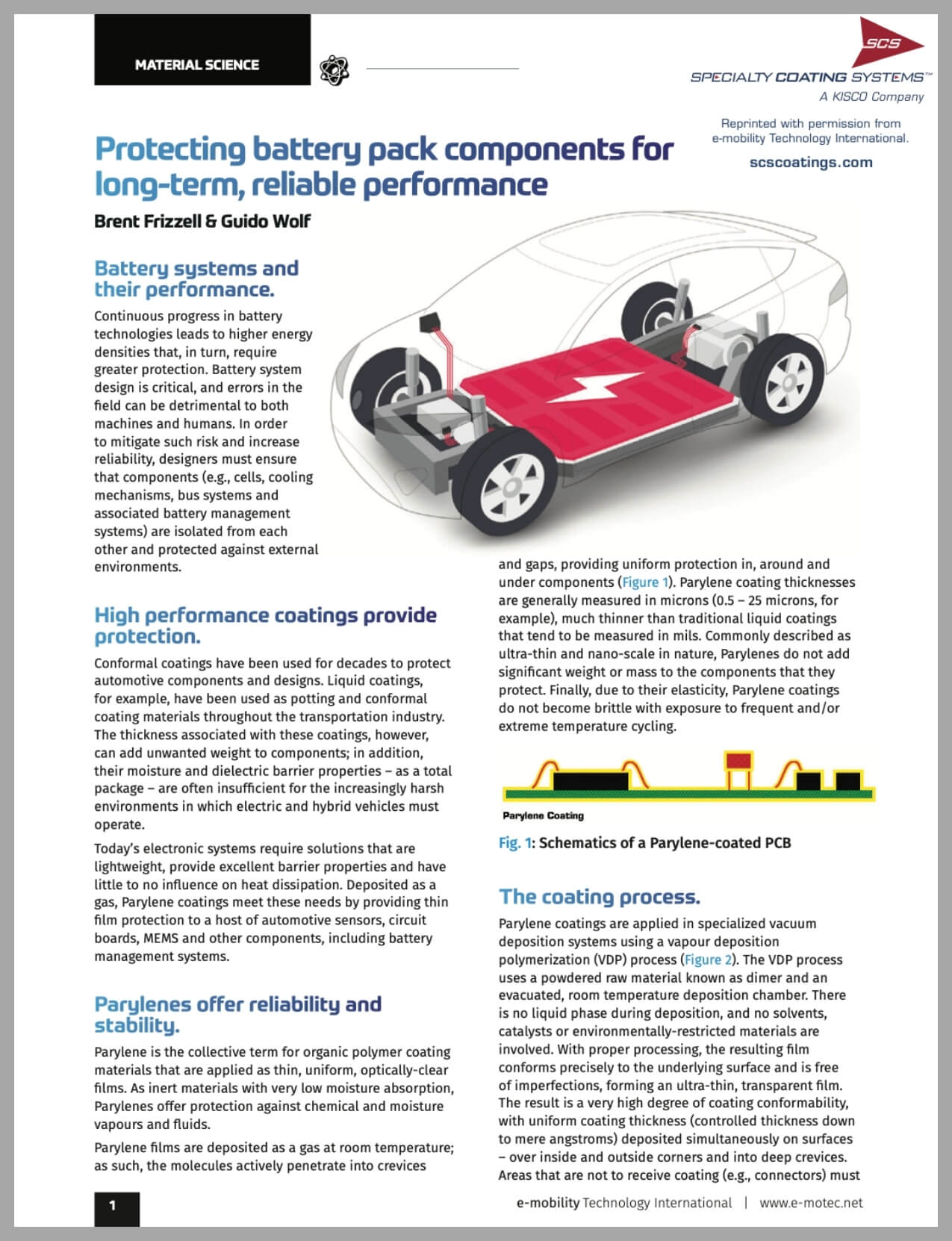

Protecting Battery Pack Components for Long-term, Reliable Performance

Continuous progress in battery technologies leads to higher energy densities that, in turn, require greater protection. Battery system design is critical, and errors in the field can be detrimental to both machines and humans. In order to mitigate such risks and increase reliability, designers must ensure that components are isolated from each other and protected against external environments. This article reviews protective options for battery applications.

PARYLENE APPLICATIONS – MILITARY/AEROSPACE

-

Parylene Coatings Can Protect COTS Electronics in Aerospace and Defense Applications

Financial considerations show that the use of COTS electronics for military applications will continue growing, so designers should protect them from heat, moisture, and radiation. The challenge is how to protect devices originally designed for non-military use without additional enclosures.

-

Advances in Lightweight Electronics Protection

As technologies continue to evolve, with components often decreasing in size and increasing in complexity, the materials used to manufacture and protect the latest components and systems are also improving. Whether used in commercial or military aircraft, rockets, satellites, terrestrial or water vessels, or the latest in unmanned air, land and sea vehicles, systems within these industries must meet similar requirements – assemblies, components and electronics must be both lightweight and designed to withstand harsh operating conditions. This article explores the lightweight and reliable protection Parylene provides to a wide range of aerospace, avionics and defense applications.

PARYLENE APPLICATIONS – FERRITES

-

Parylene Conformal Coating Benefits Coil Winding Processes

Small forms, spindles, ferrites and miniature wire-wound electric motor parts can benefit from the protection of a thin, vacuum-deposited coating.

IONIC CONTAMINATION TESTING TECHNOLOGY

-

Advances in Ionic Testing

Since the birth of the PCB, there has been a need to test for residual ionic contamination, which can lead to corrosion and dendrite growth. Whether on bare boards or finished assemblies, contamination can cause current leakage across insulating surfaces — resulting in shorts. This article explains advancements in ionic cleanliness testing, including heated dynamic ionic contamination test systems and their benefits.

-

Influences on Contamination Testing

The Ionograph was designed to be a simple, fast and accurate means of testing for ionic contamination as compared to the expensive, time consuming, and highly technical alternative of chromatography. However, the accuracy of the instrument is dependent on the condition of the Ion Extract Solution.

SPRAY COATING AND CURING

-

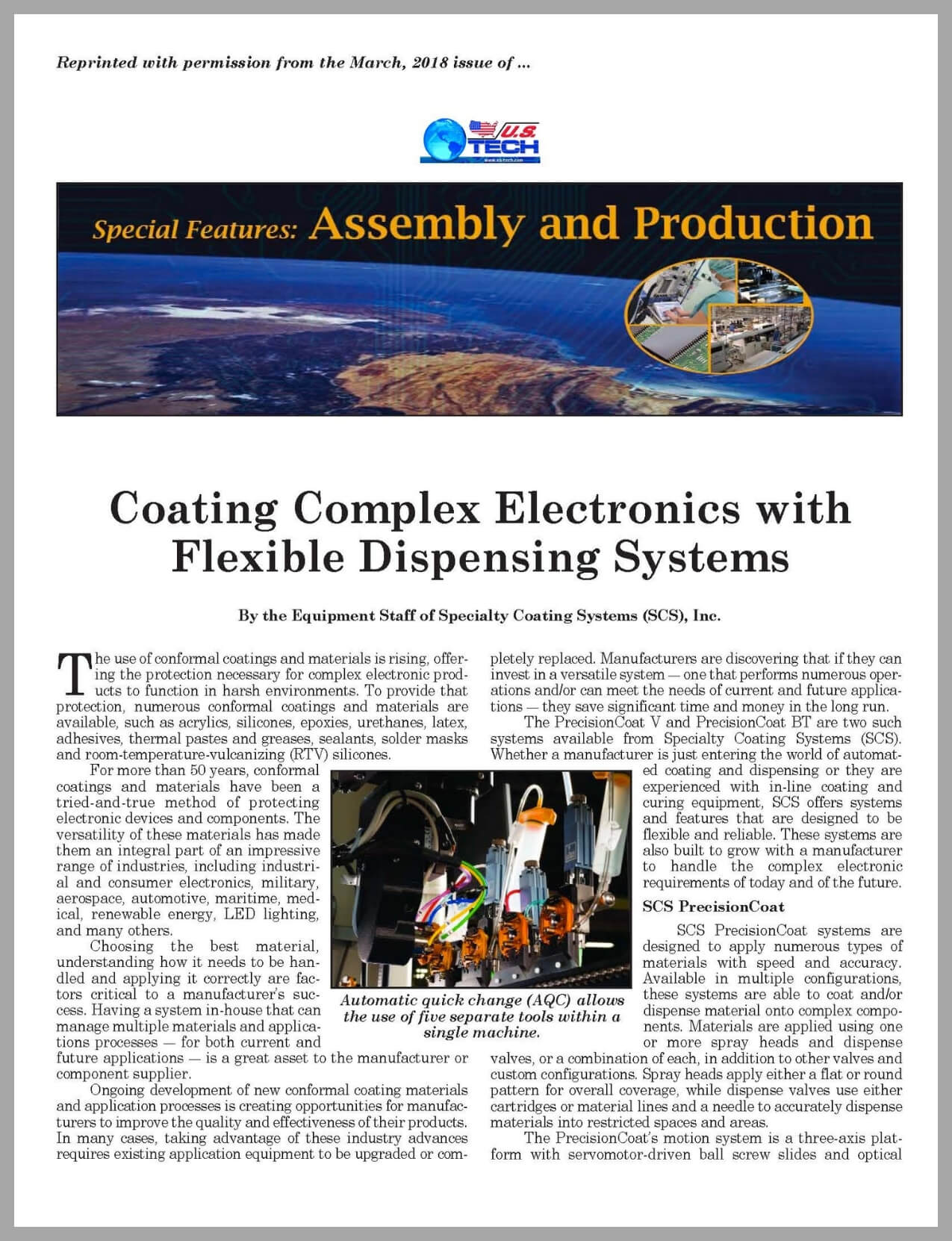

Coating Complex Electronics with Flexible Dispensing Systems

For more than 50 years, conformal coatings and materials have been a tried-and-true method of protecting electronic devices and components. Ongoing development of new conformal coating materials and application processes creates opportunities for manufacturers to improve the quality and effectiveness of their products. Manufacturers are discovering that if they can invest in a versatile system, they save significant time and money in the long run. This article looks at the unmatched flexibility the SCS PrecisionCoat line of spray coating and dispense systems offers through a wide range of valves, tools and features.

Videos

-

Parylene Conformal Coatings for the Oil & Gas Industry

Originally published by Oil & Gas Journal, this concise 30-minute webinar offers viewers an opportunity to learn more about how Parylene coatings are applied, their features, and the value they add to devices and components, including excellent chemical and moisture barrier properties, high dielectric strength per unit thickness, excellent thermal and UV stability, and low coefficient of friction. As materials and applications continue to advance and operating environments become more harsh, Parylene conformal coatings enhance the performance of oil and gas technologies.

Global Coverage Archives

GLOBAL COVERAGE 2020

-

Fall 2020

- SCS Celebrates Terry Bush, Names Tim Bender President and CEO

- SCS Newsletter Celebrates 30 Years of Publication

- Kermit Olson Celebrates 40 Years at SCS

- SCS ParyFree® Meets ISO 10993 Biocompatibility Testing Requirements

- SCS Introduces PrecisionCoat Progressive Cavity Pump Valve

GLOBAL COVERAGE 2019

-

Fall 2019

- SCS Parylene Provides Component Protection in ExoMars Mission

- SCS Complies with RoHS and REACH Directives

- SCS to Exhibit at CES® 2020

- SCS to Showcase PrecisionCoat V at IPC APEX EXPO

- SCS Webinars Available On Demand

- SCS Holds Parylene Seminars in Europe

-

Summer 2019

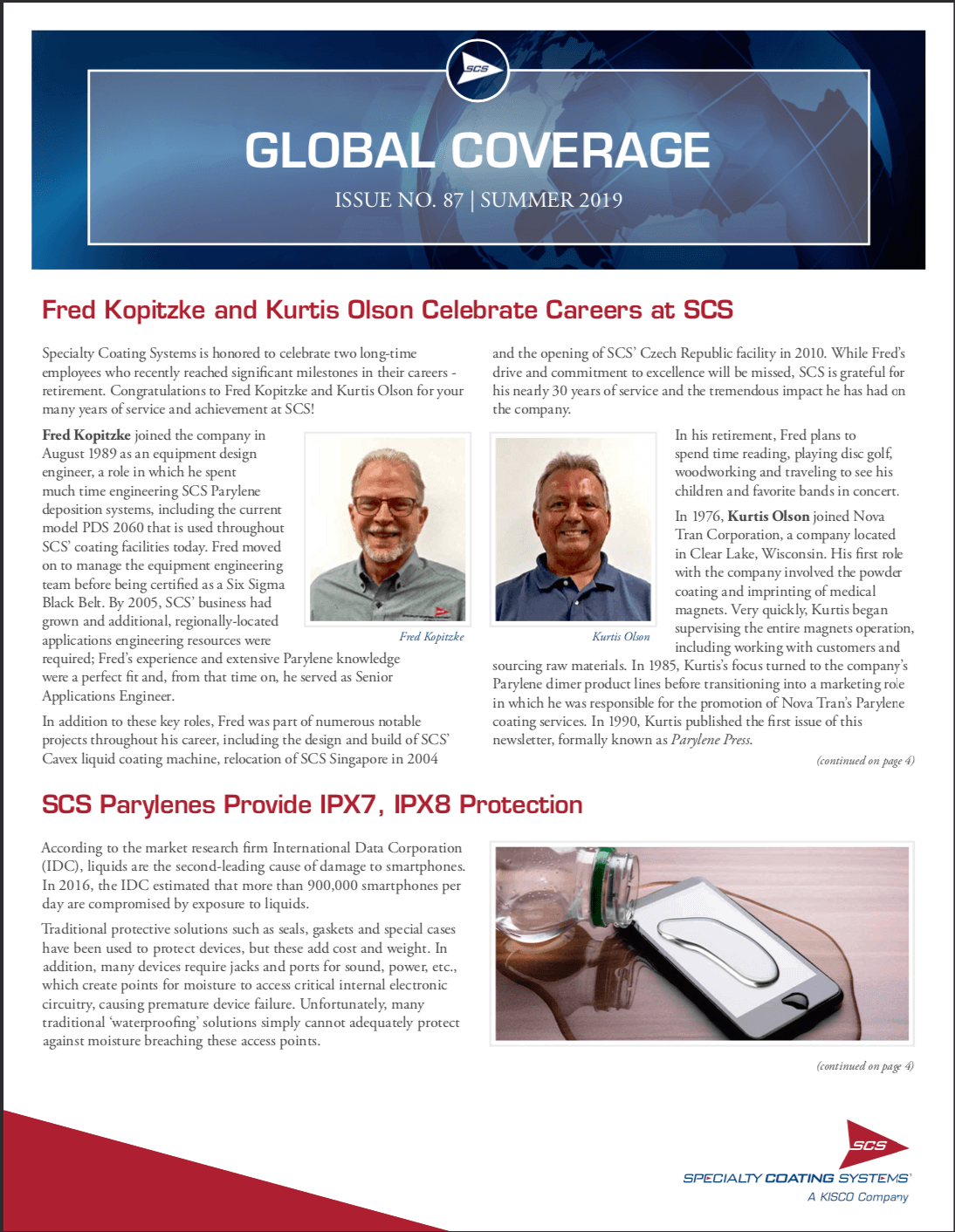

- Fred Kopitzke and Kurtis Olson Celebrate Careers at SCS

- SCS Parylenes Provide IPX7, IPX8 Protection

- SCS Material Application Valves: Engineered for Performance

- SCS Delivers Quality and Compliance for Customer Products

- Parylene and Smart Technology in Agriculture

- SCS Receives Award at SMTA China East

-

Winter 2019

- SCS Develops New Halogen-Free Parylene Coating

- CES 2019 Highlights

- Parylene’s Role in Pain Management Technology

- SCS Names Representative of the Yeare at IPC APEX EXPO

- SCS’ PrecisionCoat Programmable Valve Spacing: Enhancing Productivity and Accuracy

GLOBAL COVERAGE 2018

-

Fall 2018

- Dan Adamo Celebrates 35 Years at SCS

- Parylene Protects Consumer Electronics in Harsh Environments

- SCS Parylene C-UVF® Enables Visual Inspection

- SCS Exhibits at Sensors Midwest and SMTA International

-

Summer 2018

- Wisconsin Lt. Governor Kleefisch Tours SCS’ Clear Lake Facility

- Parylene Safeguards Performance in Emerging Medical Sensors

- SCS PrecisionCoat AQC: A Robust Solution

- SCS Presents at International Conferences

-

Winter 2018

- SCS President and CEO Celebrates 35 Years

- Parylene Protects UAVs in Harsh Environments

- Continuing the Legacy: SCS Omegameter SMD 650

- Parylene and the Future of Autonomous Vehicles

GLOBAL COVERAGE 2017

-

Spring 2017

- Bok and Mattison Celebrate 40 Years at SCS

- Introducing the PrecisionCoat BT

- Parylene Mitigates Metallic Whisker Growth

- Parylene and Emerging Medical Technologies

GLOBAL COVERAGE 2016

-

Winter 2016

- SCS Celebrates Company Milestones In 2016

- SCS Germany GmbH

- Parylene and Diabetes Management – Part 2

- Parylene and the Future of Wearable Technologies

-

Summer 2016

- Parylene is Out of This World

- Clearing the Air on Parylene – Part 3

- Parylene and Diabetes Management

-

Winter/Spring 2016

- Exciting News from Specialty Coating Systems

- Clearing the Air on Parylene – Part 2

- Parylene’s Use on External Neurostimulation Devices

- SCS Precisioncoat Tool Changer: Offering Unmatched Flexibility

GLOBAL COVERAGE 2015

-

Fall 2015

- Parylene’s Use on Implanted Neurostimulation Devices

- SCS Webinars Available Online

- Clearing the Air on Parylene

-

Spring 2015

- SCS Offers Educational Parylene Seminars

- SCS Supports Customer Regulatory Submissions

- SCS Redesigns SCS Ionograph® Systems

GLOBAL COVERAGE 2014

-

Winter 2014

- Ventilator-Associated Pneumonia and Endotracheal Tubes

- Get Connected with SCS

- Parylene 101: Physical and Mechanical Properties

-

Summer 2014

- Benefits of Cleaning Before Conformal Coating

- SCS Launches Japanese Website

- Jet Dispensing: Ready for Take-Off

-

Spring 2014

- New Features Enhance Customizable SCS Precisioncoat

- SCS Offers Parylene Seminars in Costa Rica and Germany

- Parylene Coating for Asteroid Explorer HAYABUSA 2

GLOBAL COVERAGE 2013

-

Fall 2013

- SCS Introduces microRESIST™ Antimicrobial Parylene Technology

- SCS Hosts ‘Designing Medical Devices’ Forum in Germany

- The Benefits of Parylene in Pre-filled Syringes

-

Spring 2013

- SCS “RISEs” to Meet Global Challenges

- SCS Completes Ontario Site Expansion

- SCS Announces AS9100C Certification

GLOBAL COVERAGE 2012

-

Winter 2012

- SCS Employees Celebrate 30+ Years

- Happy Holidays From SCS

- SCS Relocates Woking Coating Center

-

Summer 2012

- SCS Enhances Operational Excellence

- SCS Celebrates Ribbon Cutting in Austin

- SCS Announces HEMSA Partnership

-

Spring 2012

- SCS Achieves AS9100 Revision C Certification

- SCS Completes Amherst Site Remodel

- SCS Parylene Coatings Prolong Diesel Engine Life

GLOBAL COVERAGE 2011

-

Winter 2011

- SCS Expands Ontario Coating Center as Growth Continues

- SCS Engineering Team Lays the Foundation

- SCS Parylenes Meet Biocompatibility Standards

-

Fall 2011

- SCS Expands U.S. Parylene Coating Service Operations

- SCS Parylene C-UVF™ Fluoresces Under UV Light

- SCS Introduces New Adhesion Promotion Technology – AdPro Poly®

-

Winter/Spring 2011

- SCS Expands Indianapolis Cleanroom

- SCS Precisioncoat Features New Potting Capabilities

- The Future of Electronics

GLOBAL COVERAGE 2010

-

Summer 2010

- SCS Opens New Coating Center in Mainland Europe

- SCS Announces Fall Parylene Seminar Schedule

- Parylene Facilitates Advances in Intraocular Implant Technology

-

Spring 2010

- SCS Offers Spring European Seminars

- SCS Completes Move to New ISO Certification Level

- SCS Introduces the Precision Tri-Cure 2250 at IPC APEX Expo

GLOBAL COVERAGE 2009

-

Winter 2009

- Japan Aerospace Exploration Agency Commends Parylene Japan

- SCS and Tech Briefs Present Webinar on Conformal Coatings

- New Technologies Emerge with Parylene Structures

-

Summer 2009

- SCS Equipment Manufacturing Achieves ISO Certification

- SCS to Present Webinar on Advances in Conformal Coatings

- SCS Presents at IMAPS/SMTA Vendor’s Day and Expo

-

Spring 2009

- One-Day Parylene Seminars to Be Presented in April

- SCS Receives “Supplier of the Year” Award

- SCS Raises Standard to ISO 9001:2008

GLOBAL COVERAGE 2008

-

Winter 2008

- SCS Enhances Precisioncoat Features

- SCS Offers Parylene Workshops in Germany

- SCS Parylene Protects Hearing Assist Devices

-

Summer 2008

- Berwind Corporation Acquires Specialty Coating Systems

- SCS Singapore Grows Into New Location

- Introducing AdPro Plus™

-

Spring 2008

- Specialty Coating Systems Acquires Parylene Japan K.K.

- SCS Expands Clear Lake Coating Center

- SCS Unveils Precisioncoat RTV at APEX 2008

GLOBAL COVERAGE 2006

-

Spring 2006

- SCS Opens Costa Rica Facility

- SCS Introduces Precisioncoat Spray Coating Systems

- Precision UVC Mates Seamlessly with Precisioncoat Systems

GLOBAL COVERAGE 2005

-

Spring 2005

- SCS Parylene Increases Automotive Component Life

- SCS Parylene HT Stabilizes Insect Samples

- Back to Basics – A Parylene Review

GLOBAL COVERAGE 2004

-

Fall 2004

- SCS Expands into Shanghai, China

- SCS Embraces Six Sigma Culture

- New G3P Spincoat Software Improves Productivity

-

Spring 2004

- SCS Cleanroom Changes the Parylene Coating Paradigm

- SCS Ionograph Test Module Introduced

- Parylene Update – Medical Coating Applications

-

Winter 2004

- New PDS 2035CR Coater Fills Important Niche

- Endometrial Ablation Tool Benefits from Parylene Properties

- Steps to Quality Control in Parylene Operations

GLOBAL COVERAGE 2003

-

Fall 2003

- Parylene Coating Offers Moisture Barrier Potential for LEDs

- SCS Continues International Expansion

- Parylene Hits Prime Time TV

GLOBAL COVERAGE 2002

-

Winter 2002

- SCS Committed to Parylene Technology Advancement

- SCS Offers Contamination Test Services

-

Fall 2002

- Mars Orbital Camera Image Count Passes 100,000

- SCS Parylene Conservation to be Highlighted in Learning Channel Special

-

Spring 2002

- SCS Marks Newsletter’s 12th Year

- Coating Centers are ISO Certified

- Parylene – A Historical Review

GLOBAL COVERAGE 2001

-

Winter 2001

- Ruggedized Computers Protected by Parylene

- Selective Coating Equipment Moved to Speedline CAMALOT

- Repair and Recoating of Parylene-Coated Circuits

-

Fall 2001

- Parylene Protects Satellite Thruster Control Electronics

- SCS Completes New Biocompatibilty Tests

- New Programmable Deposition System

-

Summer 2001

- SCS Selects Business Partner in China

- SCS Quantifies Parylene Sterilization Performance

- Parylene Temperature Performance

-

Spring 2001

- Parylene Benefits Microscopic Machines

- AMC Chooses Parylene for Medical Implant

- SCS Relocating to New Headquarters

GLOBAL COVERAGE 2000

-

Winter 2000

- Union Switch Cuts Coating Costs

- SCS Receives Medtronic Recognition

- Compact Cure System

-

Fall 2000

- Parylene Selected for Alternative Fuel System

- SCS’s Humphrey Explores Anthropology Application

- SCS Coating Center QS Certified

-

Summer 2000

- Selective Coating Improves Bose Production

- SCS Paper to be Presented at St. Petersburg Conference

- Parylene Japan K.K. Celebrates 10 Years

-

Spring 2000

- Tenth Anniversary Issue

- Speedline Offers Integrated Manufacturing Capabilities

- SPIDA Helps Panasonic Refine Processes

GLOBAL COVERAGE 1999

-

Winter 1999

- Titanic Surfaces Again at SCS

- New Thermal Cure Unit Supports Selective Coating

- Tumble Coat Advancement

-

Fall 1999

- Parylene Supports Deep Space Propulsion Test

- Spin Coating Basics – Common Defects

- Increasing Selective Coating Throughput

-

Spring 1999

- Teamwork Drives Fast Production Upgrade

- SCS Coats Two-Sides at NEPCON West

- UV Ovens Cure Textured Films

GLOBAL COVERAGE 1998

-

Fall 1998

- Parylene Supports the International Space Station

- Labcoter®2 Portable Parylene Coating System

- SCS europe Unified With New Name