Application Evolution

Parylene Application Evolution

Advancing with electronics.

When Parylene was first commercialized, it was used as a conformal coating for the small ferrite rings used in core memory, but as technology advanced, Parylene expanded into protecting premium printed circuit boards in the electronics industry. Over the years, as industry expanded with innovation after innovation so, too, did the use of Parylene.

A perfect fit for aerospace.

Parylene’s high altitude/vacuum performance started gaining attention within the aerospace industry in the 1970’s. Parylene’s inherent barrier properties were important, but even more so was the nature of its vacuum deposition process (VDP). Being deposited in a vacuum meant the Parylene trapped no air in or on a coated device or component. In high altitude/lower pressure environments, this trapped air can expand and potentially rupture the coating. The result is not only a destroyed device but also the potential for a destroyed mission as well. Parylene also has higher temperature capabilities in the absence of oxygen — the vacuum of deep space. Add the low mass of these very thin Parylene coatings, and it’s clear to see why SCS Parylene is a highly prized within the aerospace industry.

Applications grow with a new Parylene.

As applications ranging from automotive to defense started to discover Parylene’s many performance and reliability features, the demand for an additional set of characteristics started to appear. SCS engineers saw the opportunity and pursued a new Parylene, one with higher temperature capabilities and the ability to survive in UV environments. The result was SCS Parylene HT®. During the past decade, this new generation of Parylene has expanded the application use in transportation and defense applications as well as the growing outdoor signage industry.

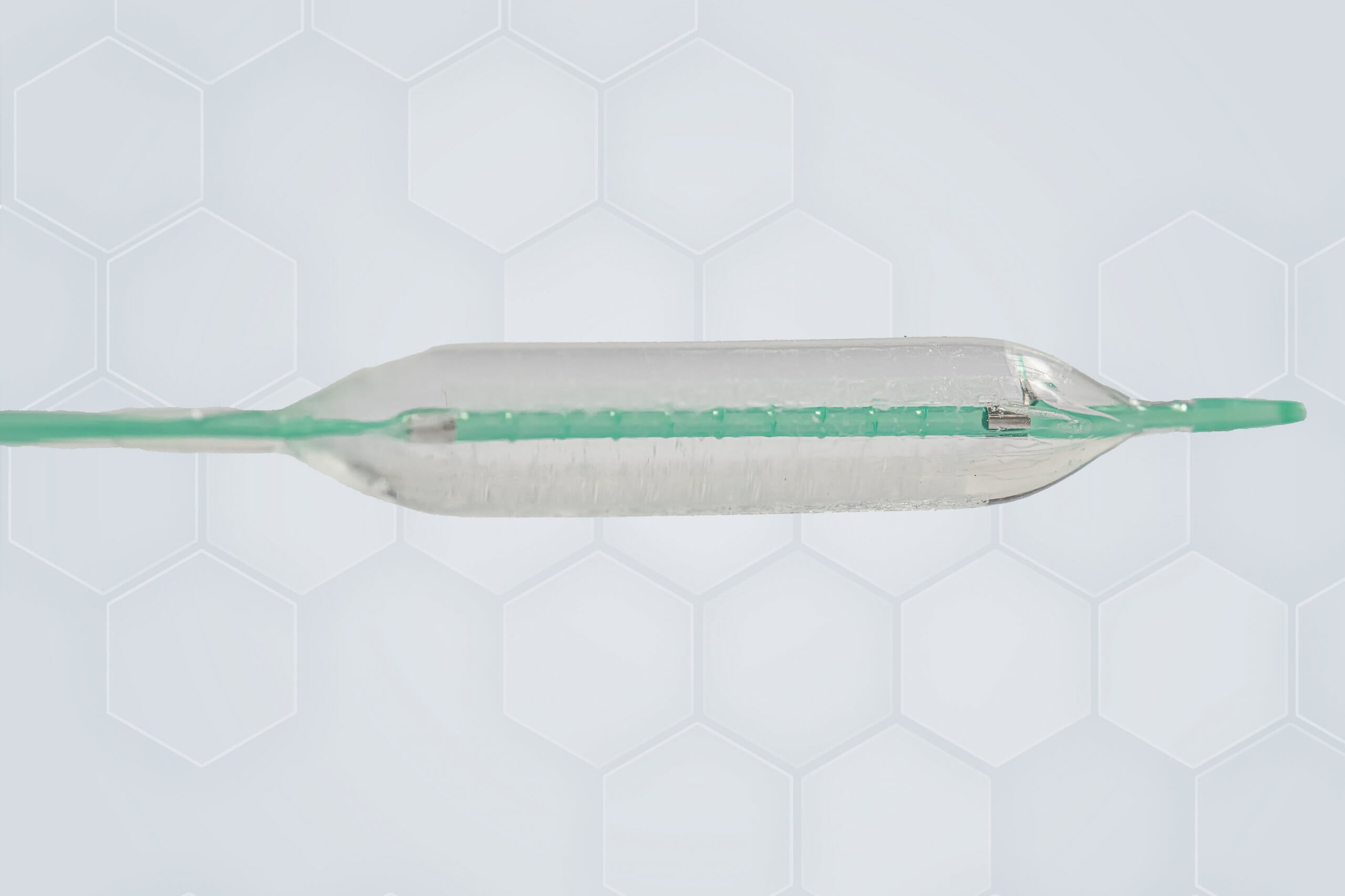

A natural for the medical industry.

Early in its commercialization, Parylene was being reviewed by a number of forward thinkers including those in the medical device industry. They started to recognize Parylene’s ability to provide unique performance capabilities in very thin coatings. Even more intriguing was the discovery that Parylenes’ N and C were inherently biocompatible. Today, Parylene is used in and on pacemakers as it has for 50 years. Parylene is also now being used on coronary and cerebral stents. This includes drug-eluting stents (DES) that feature drug/polymer combinations. In DES applications, the Parylene serves as a critical tielayer or primer that enables the drug/polymer combinations to be integrated where normally they would not.

Making a difference in the micro world.

One of the most recent applications to take advantage of Parylene is the world of Microelectromechanical Systems (MEMS) and Motes. The micro- and nano- dimensions of these devices demand a coating that provides ultra thin, microscopic uniformity — a feature not available with coatings that are applied via brush, spray or by dip process. SCS Parylene has proven to be a perfect fit for MEMS and Motes thanks to its vapor deposition processing and sub-micron layer performance.

A new dimension in Parylene applications.

While Parylene conformal coatings continue to expand in many industries and applications, we are also entering a new phase in the evolution of Parylene applications. Generically referred to as 3-dimensional applications, this new frontier is now being perused by researchers who are working to create 3-D structures made entirely of Parylene. These devices fall into the category of MEMS, and promise a new wave of commercialization of Parylene.