SCS Blog

Recent SCS Blogs

Nanocoatings for Electronics

The significance of polymeric conformal coatings in safeguarding printed circuit boards (PCBs) from functional impediments like dust, corrosion, moisture, and temperature fluctuations is widely recognized. What may be less apparent is that as electrical components in PCBs shrink, conventional conformal films are proportionally less effective for certain coating purposes. With the emergence of microelectromechanical systems... Read More >>

Automotive Conformal Coatings: Silicone vs Parylene

Conformal coatings have long played a crucial role in protecting printed circuit boards (PCBs) and vital automotive electronics from challenging conditions. Their significance in automotive design and manufacturing has only grown over time. Delicate electronic components and their connections necessitate shielding to ensure consistent performance. By adapting to the topographies of PCBs, these coatings insulate... Read More >>

Parylene and Ruggedization

Ruggedized products are designed to operate reliably in the harshest conditions imaginable. From embedded systems tailored for military applications to specialized research mobile computers and aerospace industry components, these items are built to endure excessive moisture, aridity, severe temperatures, intense vibrations, strong winds, and even the absence of atmosphere. The internal components of these products... Read More >>

How Long does Parylene Coating Last?

The stability and insulation properties of Parylene conformal coating are critical for the reliable operation of electronic devices throughout their lifetime (PCBs, MEMS, sensors, implants and so on.). The failure mechanism of the conformal coating layers is known to be due to pore formation, blistering, delamination and thinning or pinhole formation due to dielectric breakage... Read More >>

Updates on Conformal Coating and Tin Whiskers

Electrically conductive tin whiskers, though not fully understood, are crystalline structures measuring between 1-2 mm. These structures can emerge from surfaces where tin serves as the final finish, with surfaces treated with electroplated tin being particularly prone to whisker growth. While first observed in the 1940s, a definitive solution to prevent their growth remains elusive,... Read More >>

Different Types of Parylene

Parylene, a widely used term for Poly-para-xylylene, creates a protective plastic film when coated on substrate surfaces. This coating process is carried out using chemical vapor deposition (CVD) in a vacuum environment, where the gas is applied to specific substrate surfaces. Parylene films offer remarkable versatility, protecting substrates with a reliable barrier against acids, caustic... Read More >>

Improving Patient Outcomes with Parylene-Coated Stents

Coronary and neurovascular stents are tubular medical implants that act as a supportive framework, enhancing vascular structure. They are utilized to unblock or widen arteries, aiming to increase blood flow and lower the risk of cardiac events like heart attacks. Parylene conformal coating provides critical function to these support structures. Parylene’s use on stents has... Read More >>

Three Common Medical Applications for Parylene

Parylene conformal coating boasts a multitude of benefits and properties that make it an appealing choice for a variety of medical device applications. Chief among Parylene’s advantages for medical applications, however, is that it meets USP Class VI and ISO 10993 biocompatibility requirements—a characteristic that is essential for many critical medical products. Additional benefits of... Read More >>

Coating Spotlight: SCS Epoxy Conformal Coatings

Epoxy resin (ER) conformal coatings provide robust protection against chemical solvents and moisture exposure for applications in the electronics, defense and aerospace industries. Commonly used epoxy conformal coatings include MG Chemicals 4225, HumiSeal® 2A53 and Henkel Loctite® EC 210. As a family, epoxies generally offer stronger abrasion resistance properties than most coatings; they also provide... Read More >>

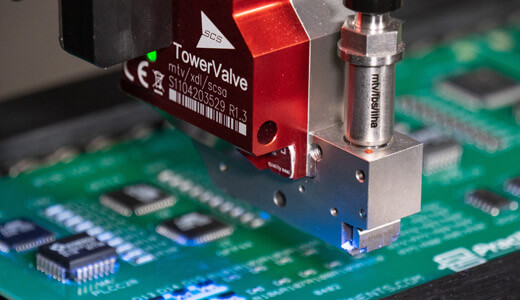

SCS Tower Jet Valve Offers Unmatched Control and Flexibility

As an industry leader in the design and manufacture of conformal coating systems, SCS continues to develop system features that are focused on improving coating accuracy, efficiency and productivity. The SCS tower jet valve for the PrecisionCoat line of spray coating and dispense systems provides manufacturers exceptional flexibility. The jetting valve features piezo control motor... Read More >>