<< View SCS Blog

Navigating Conformal Coating Removal: Methods and Materials

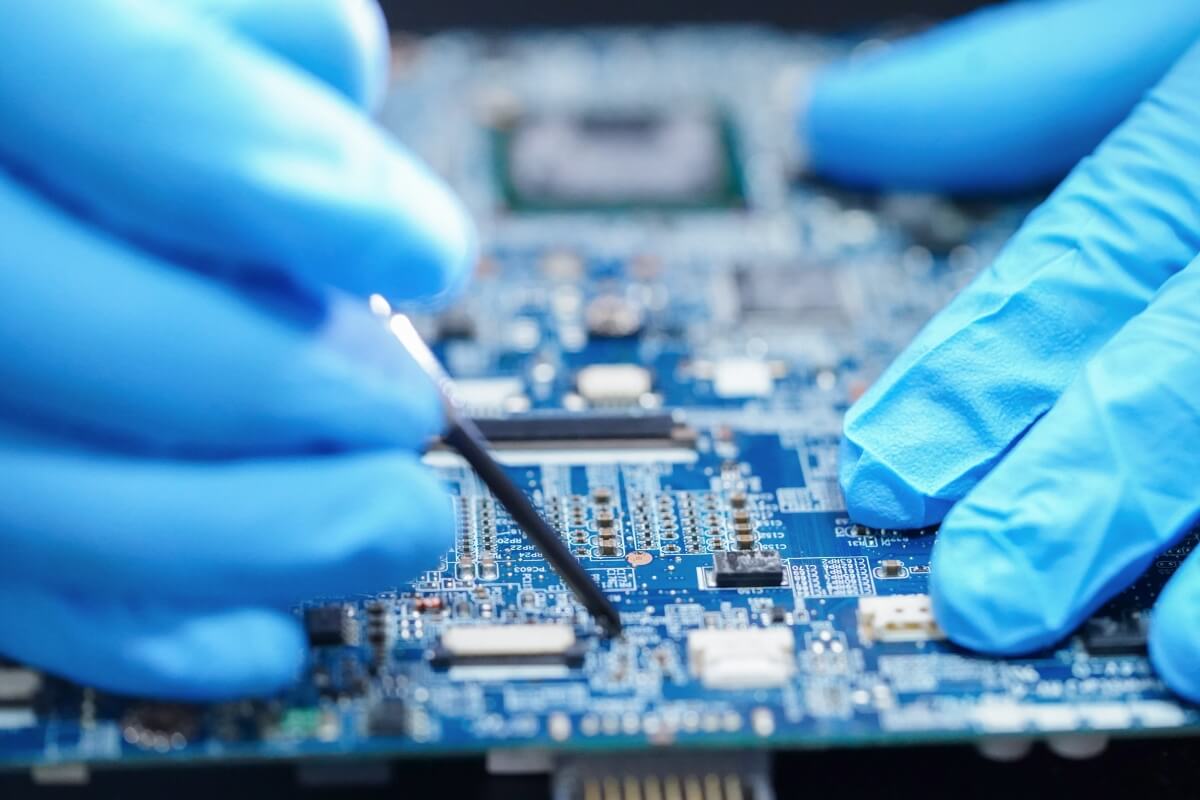

Conformal coatings safeguard electronic components from environmental hazards, including exposure to moisture, chemicals and other contaminants. However, there may come a time when a protective coating must be removed for repairs or modifications to the component. Liquid conformal coatings such as acrylics, silicones or urethane are often utilized when frequent rework or board repairs are anticipated. Parylene coatings can also be removed for board rework; however, due to their robust properties, special techniques are required. In general, the method of coating removal can vary depending upon the extent of removal needed (partial or complete), type of coating and nature of the required repair.

Chemical Solvents: The goal of a chemical solvent (e.g., acetone or isopropyl alcohol, etc.) is to dissolve the coating without harming the underlying components. If the coating is more robust, like a urethane coating, removal may require harsher chemicals. Care must be taken to avoid chemical damage to the component.

Mechanical Abrasion: Mechanical methods involve manually scraping, blasting or brushing the coating off the PCB surface. Mechanical abrasion may also be used to selectively remove the coating as opposed to exposing the entire PCB to chemical solvents. Excessive force must be avoided to prevent damage to the underlying substrate.

Thermal Techniques: Thermal methods can soften a coating using heat from hot air guns or infrared systems. Precision control is crucial to prevent component damage, especially to the underlying substrate.

It is necessary to consider various factors when determining the method of coating removal. First and foremost, the removal technique must align with the specific coating type used. Additional considerations include environmental impact (e.g., wastes, fumes, etc.), the possibility of future removal or recoating, ease of disposal and the speed at which the coating can be removed. Moreover, the amount of time that a coating has been utilized on an underlying substrate can also influence the difficulty of removal.

Selecting the appropriate conformal coating removal method and material ensures electronics can be safely and effectively maintained. This approach optimizes circuit board performance while minimizing the risk of damaging the underlying substrate. For more information on conformal coatings and rework solutions, contact SCS online or call +1.317.244.1200.

Global Coverage Issue 98, Spring 2024