PFAS-Free Parylenes

PFAS-free Parylene coatings provide dry-film lubricity for mandrels and other medical wires

The low coefficients of friction of SCS Parylenes make them an ideal lubricious coating for a variety of medical wires, including guidewires and mandrels. As long chain polymers, Parylenes can also significantly improve the safety and utility of components by eliminating flaking and delamination. In addition, as global regulations move to eliminate the use of per- and polyfluoroalkyl substances (PFAS), Parylene coatings offer a PFAS-free alternative to wires previously coated with PTFE.

Benefits of SCS Parylenes include:

- Ultra-thin and conformal

- Biocompatible and biostable

- PFAS-free

- Low coefficients of friction / high dry-film lubricity

- Thermal stability

- Excellent moisture and chemical barrier

- Excellent dielectric properties

- Excellent crevice and multi-layer penetration

- Ultra-thin films add minimal mass to delicate components

PRODUCT BROCHURE

SCS Medical Coatings

Vital performance and protection for medical device applications.

For more than 50 years, SCS has applied its medical coating experience and technologies to support a range of medical device applications from elastomeric seals and forming mandrels to electrosurgical tools, infusion devices and long-term implants such as pacemakers and stents. SCS offers biocompatible and biostable coating solutions for medical devices and components to ensure excellent moisture, chemical and dielectric barrier protection. Additionally, low coefficient of friction options are available for applications where dry film lubricity is important.

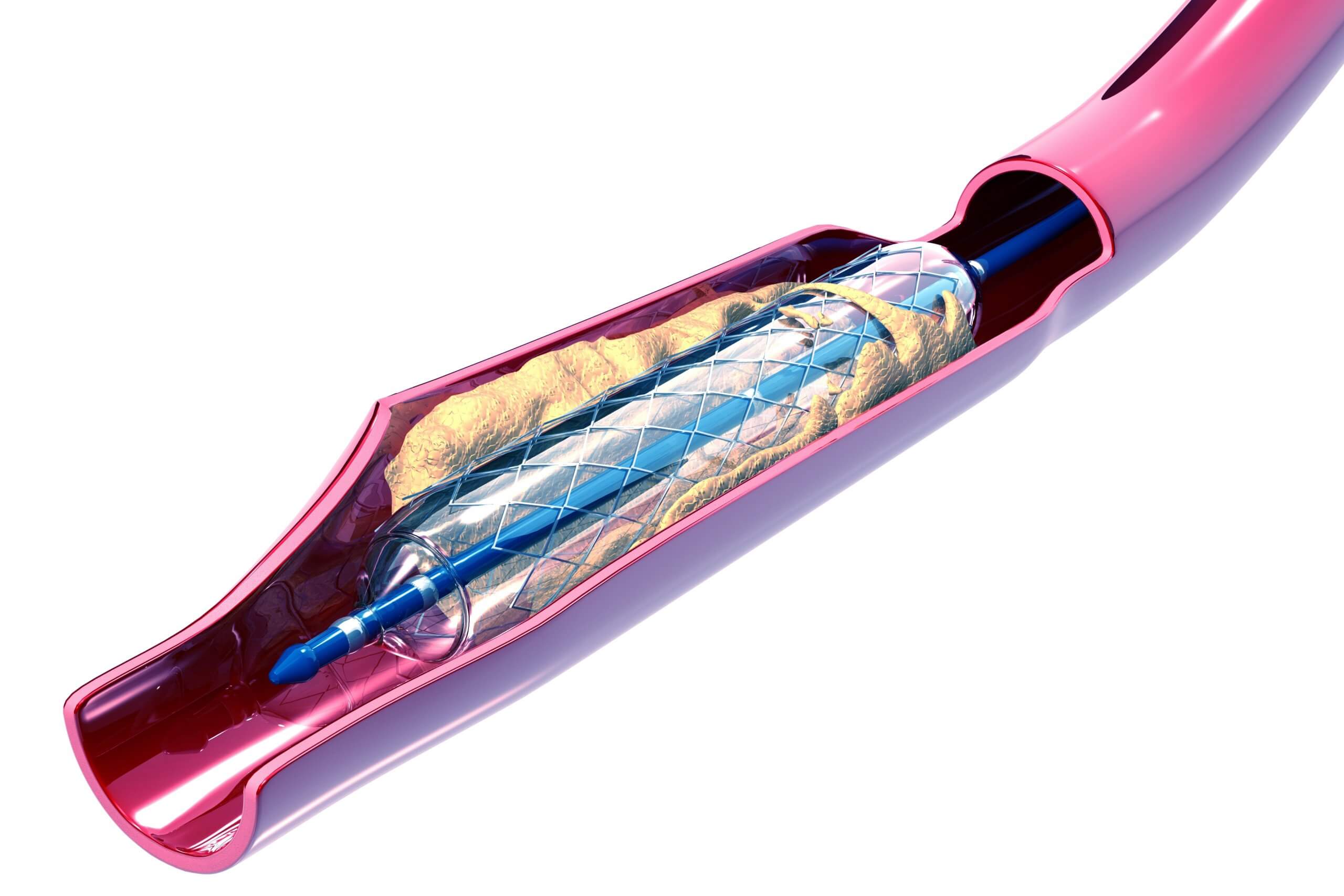

The Use of Parylene-Coated Mandrels in the Balloon Catheter Manufacturing Process

Wire-forming mandrels range from a few inches to 120 inches in length and are typically fashioned from medical-grade stainless steel with highly-specialized varieties made from other exotic alloys, including the shape memory alloy known as Nitinol.

Read More