<< View SCS Blog

SCS Tower Jet Valve Offers Unmatched Control and Flexibility

As an industry leader in the design and manufacture of conformal coating systems, SCS continues to develop system features that are focused on improving coating accuracy, efficiency and productivity.

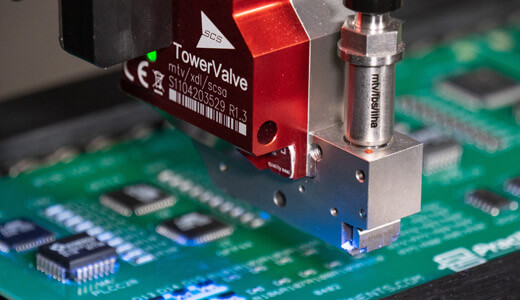

The SCS tower jet valve for the PrecisionCoat line of spray coating and dispense systems provides manufacturers exceptional flexibility. The jetting valve features piezo control motor technology, ensuring superior uniformity and repeatability to meet unique material dispensing needs.

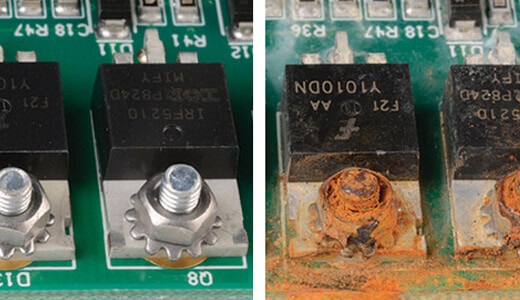

The SCS tower jet valve precisely dispenses small amounts of material using physical force to separate specific volumes of material into microdroplets. The valve’s piezo control motor allows the rate of closure and opening to be altered to meet the material’s energy requirements. This controlled dispense approach enables the jetting valve’s pulse to be wide and high for high-viscosity materials and narrow for low-viscosity materials, providing users with increased flexibility. Furthermore, the nozzle orifice and shape can be changed to adapt to substrate features and variations in materials.

The tower jet valve is commonly used to apply single-part coating materials such as acrylics, urethanes and silicones; its precise application eliminates the need for complex masking and removal. Additionally, the valve can be utilized for some solid material powders in suspension (e.g., solder alloys) and can apply glue in a pattern elevation, which enhances the adhesive hold through compression.

The fully programmable, multi-purpose PrecisionCoat VI offers unparalleled programming for efficiency in automated material applications. When paired with the SCS tower jet valve, it delivers exceptional material application in a modular platform, bringing flexibility to projects without sacrificing quality or performance.

To learn more about the SCS PrecisionCoat VI and tower jet valve, visit scsequip.com.

Global Coverage Issue 95, Summer 2023