Spin Coating Systems

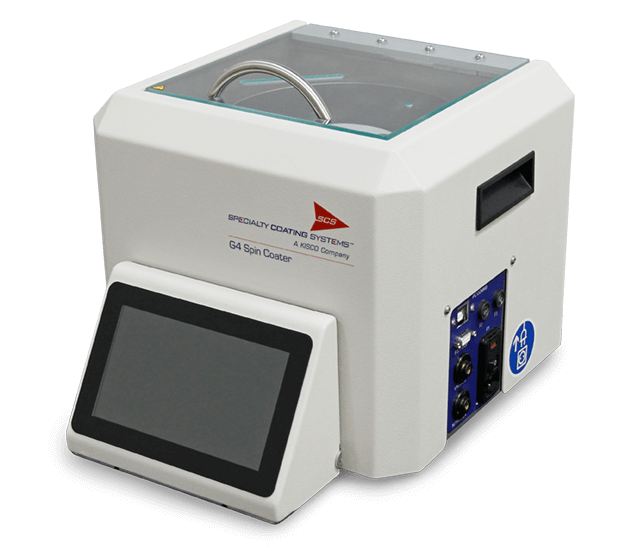

G4 Spin Coater Series

The SCS G4 Spin Coater series offers a compact design that is packed with performance features, providing precision and control for efficient coating application development. With a number of optional features, it is designed to meet diverse needs.

Product Information

The SCS G4 Spin Coater series sets the standard in operating precision and programming flexibility. SCS spin coaters are engineered to provide a high level of rotation accuracy and repeatability, along with precise acceleration and deceleration control. The result is a spin coating solution that meets specific lab requirements with a high level of performance that delivers confidence with every coating application.

Available with eight- or twelve-inch bowl sizes, fully programmable G4 Spin Coaters can store and execute up to 30 programs with 20 steps each, providing excellent flexibility. Designed with user convenience in mind, the spin coaters feature a removable touchscreen, making them ideal for use in fume hoods and glove box configurations.

System Features

- Fast, simple programming with microprocessor-based control and user-friendly touchscreen display

- Stores and executes up to 30 programs, with up to 20 steps each

- Precise repeatability from cycle to cycle

- Closed-loop servomotor for precise speed regulation

- Spin profiles adjustable in 1.0 rpm rotation increments, 0.1 second timing increments, and 1.0 second increments for dwell time

- Removable touchscreen tethered with 6-foot cable

- Compact enclosure size

- Available with eight- or twelve-inch PTFE-coated bowls

- Rear bowl drain port

- Interlocking hinged cover

- Tempered glass or impact-resistant PVC lid

Optional Features

- Windows®- compatible software that features Bluetooth® wireless communication

- Foot pedal

- Fume exhaust adapter

- Manual dispense

- Automated dispense (SCS Multi-Dispense)

Windows© is a registered trademark of the Microsoft group of companies.

Bluetooth© is a registered trademark of Bluetooth SIG, Inc.

SCS offers several chucks for use in our SCS Spin Coaters. Our chucks are machined to close tolerances and provide an exceptionally flat, rigid surface for mounting substrates of different sizes, weights and shapes. SCS can also provide custom chucks depending on your application.

Stainless steel and hard anodized aluminum accessory chucks are available for a variety of substrate types and dimensions. Be sure to specify the material of choice and chuck size when ordering.

Type CS: Flat Surface Cross and Scroll

Used to hold a thin, planar substrate such as silicon, glass or germanium on. Evenly distributes vacuum force on the substrate.

Type H: O-Ring Vacuum-Holding

Used to hold relative heavy substrates, such as glass, quartz, ceramic and metal. Includes O-ring vacuum seal.

Type L: O-Ring Vacuum-Holding

with Mechanical Locating Fingers Designed for heavy, large or asymmetrical substrates. Guide fingers assist in positioning and holding substrates. Includes an O-ring vacuum seal.

Note: Derlin® chucks are available per special order. Delrin is a registered trademark of E.I. du Pont de Nemours and Company.

Specifications