MULTILAYER COATING EQUIPMENT

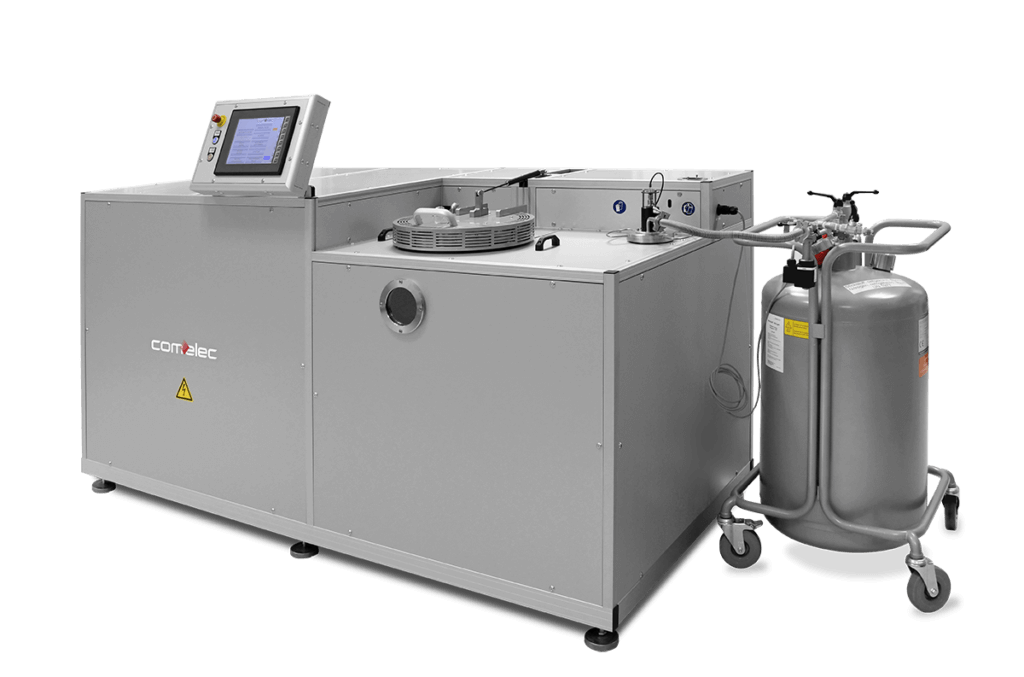

Comelec C30H ALD

The Comelec C30H ALD precisely layers Parylene and ALD for optimal barrier protection and efficient production.

Product Information

The Comelec C30H ALD multilayer deposition system’s size and performance capabilities are designed for research and testing and industrial production settings. It is well-suited to apply multilayer conformal coatings for complex, three-dimensional components used in electronics, medical devices, conductors and similar applications.

The C30H ALD layers Parylene and inorganic layers, specifically aluminum hydroxide (AL2O3) and/or titanium hydroxide (TiO2) using a remote plasma source to generate precursors that will trigger the surface reactions necessary to “grow” the layers of Parylene and ALD. The system is also equipped with a gas panel with four heated precursor lines to increase vapor pressure and temperature for precise results.

System Features

- Thermalized chamber with double-wall technology

- Patented low-contamination door

- Fully automated process with user-configurable operation parameters

- Remote plasma source

- Gas panel with 4 heated precursors

- Remote access interface using a standard browser

- Simplified maintenance design with improved access to key areas

Optional Features

- Clean room installation

- Bar code placement for traceability

- Advanced interface and web user experience

- Integrated pulley for tooling placement and removal

- Additional heated precursor lines

Specifications

Comelec C30H ALD

Overall dimension (L x W x H)

88.5 x 46 x 57 in / 225 x 116 x 145 cm

Weight

771.6 lb / 350 kg

Chamber size

11. 6 x 14.5 in / 29.5 x 37 cm

Tooling size

10.2 x 12.6 in / 26 x 32 cm

Max tooling load

220 lb / 100 kg

Dimer capacity

0.33 lb / 150 g

Power

3 x 400 V + N + PE – 50 Hz, 3 x 25A – 15kW

Thermalized chamber power

3 x 400V + PE – 50Hz

3x 14A – 9kW

3x 14A – 9kW

Thermalized chamber temperature range

20°C – 80°C

Remote plasma source

Frequency: 1.7 – 3MHz, Power: 3000W

Process temperature

Parylene: room temperature, ALD: 60°C - 80°C