MULTILAYER COATING EQUIPMENT

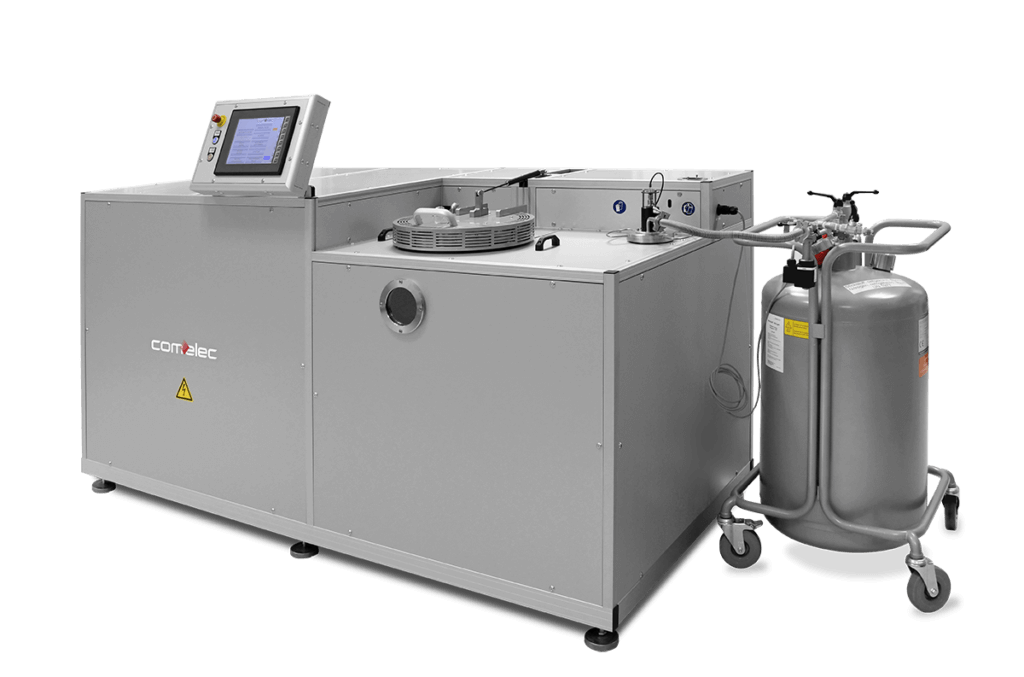

Comelec C30H ALD

The Comelec C30H ALD is designed for laboratory research and testing, precisely depositing layers of aluminum oxide (Al₂O₃) and titanium oxide (TiO₂).

Product Information

The Comelec C30H ALD multilayer deposition system’s size and performance capabilities are well-suited to apply multilayer conformal coatings for complex, three-dimensional components used in electronics, medical devices, conductors and similar applications in laboratory settings.

The C30H ALD layers Parylene and inorganic layers, specifically aluminum oxide (Al2O3) and/or titanium oxide (TiO2) using a remote plasma source to generate precursors that will trigger the surface reactions necessary to “grow” the layers of Parylene and ALD. The system is also equipped with a gas panel with four heated precursor lines to increase vapor pressure and temperature for precise results.

System Features

- Thermalized chamber with double-wall technology

- Patented low-contamination door

- Fully automated process with user-configurable operation parameters

- Remote plasma source

- Gas panel with 4 heated precursors

- Remote access interface using a standard browser

- Simplified maintenance design with improved access to key areas

Optional Features

- Clean room installation

- Bar code placement for traceability

- Advanced interface and web user experience

- Integrated pulley for tooling placement and removal

- Additional heated precursor lines

Specifications

Comelec C30H ALD

Overall dimension (L x W x H)

88.5 x 46 x 57 in / 225 x 116 x 145 cm

Weight

771.6 lb / 350 kg

Chamber size

11. 6 x 14.5 in / 29.5 x 37 cm

Tooling size

10.2 x 12.6 in / 26 x 32 cm

Max tooling load

220 lb / 100 kg

Dimer capacity

0.33 lb / 150 g

Power

3 x 400 V + N + PE – 50 Hz, 3 x 25A – 15kW

Thermalized chamber power

3 x 400V + PE – 50Hz

3x 14A – 9kW

3x 14A – 9kW

Thermalized chamber temperature range

20°C – 80°C

Remote plasma source

Frequency: 1.7 – 3MHz, Power: 3000W

Process temperature

Parylene: room temperature, ALD: 60°C - 80°C