Multilayer Coating Equipment

Multilayer Coating Equipment

Cutting-edge coating technology.

Multilayer coatings are stacked structures alternating different thin films. In Parylene-based multilayer coatings, ultra-thin layers of Parylene alternate with layers of inorganic material to ensure the highest level of reliability, performance and protection. In the past, conventional methods of application required separate equipment – one machine to apply Parylene layers and one for inorganic layers. While the results were excellent, alternating between the two systems increased both production time and cost. Today, SCS offers R&D laboratories innovative, multilayer hybrid equipment that layers Parylene with inorganic materials in a single machine, achieving comprehensive encapsulation while significantly reducing production time and cost.

These hybrid deposition chambers integrate dedicated independent gas panels, pumping lines and other separate functions in a fully modular and independent design. SCS CE-certified multilayer coating systems are available in two configurations.

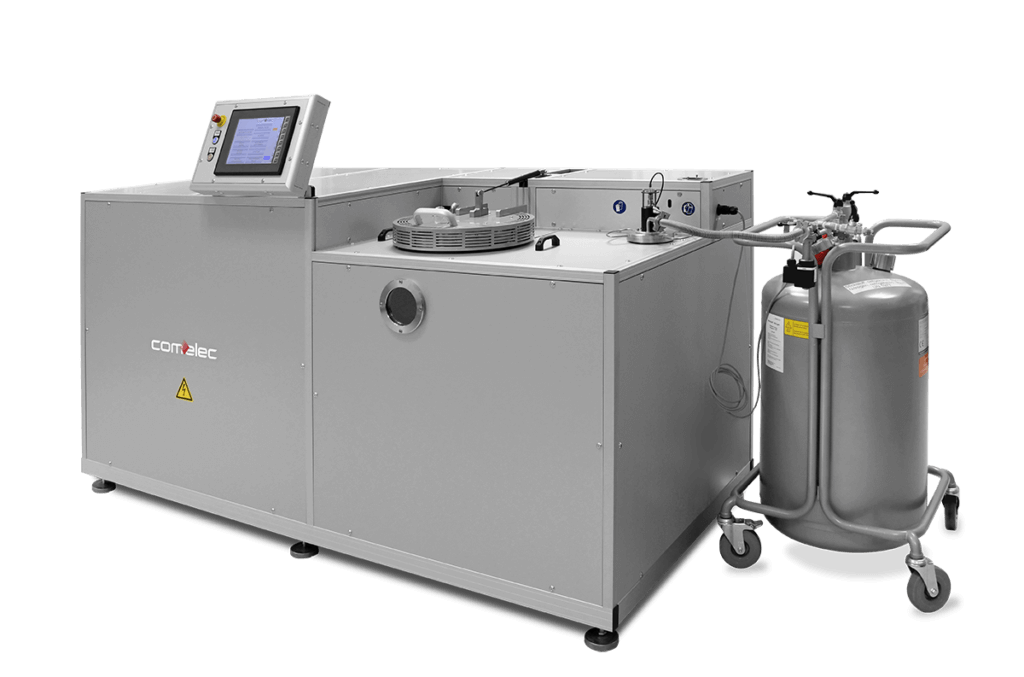

Comelec C30H ALD

The Comelec C30H ALD is designed for laboratory research and testing, precisely depositing layers of aluminum oxide (Al₂O₃) and titanium oxide (TiO₂).

More About Comelec C30H ALD