Ionic Contamination Test Systems

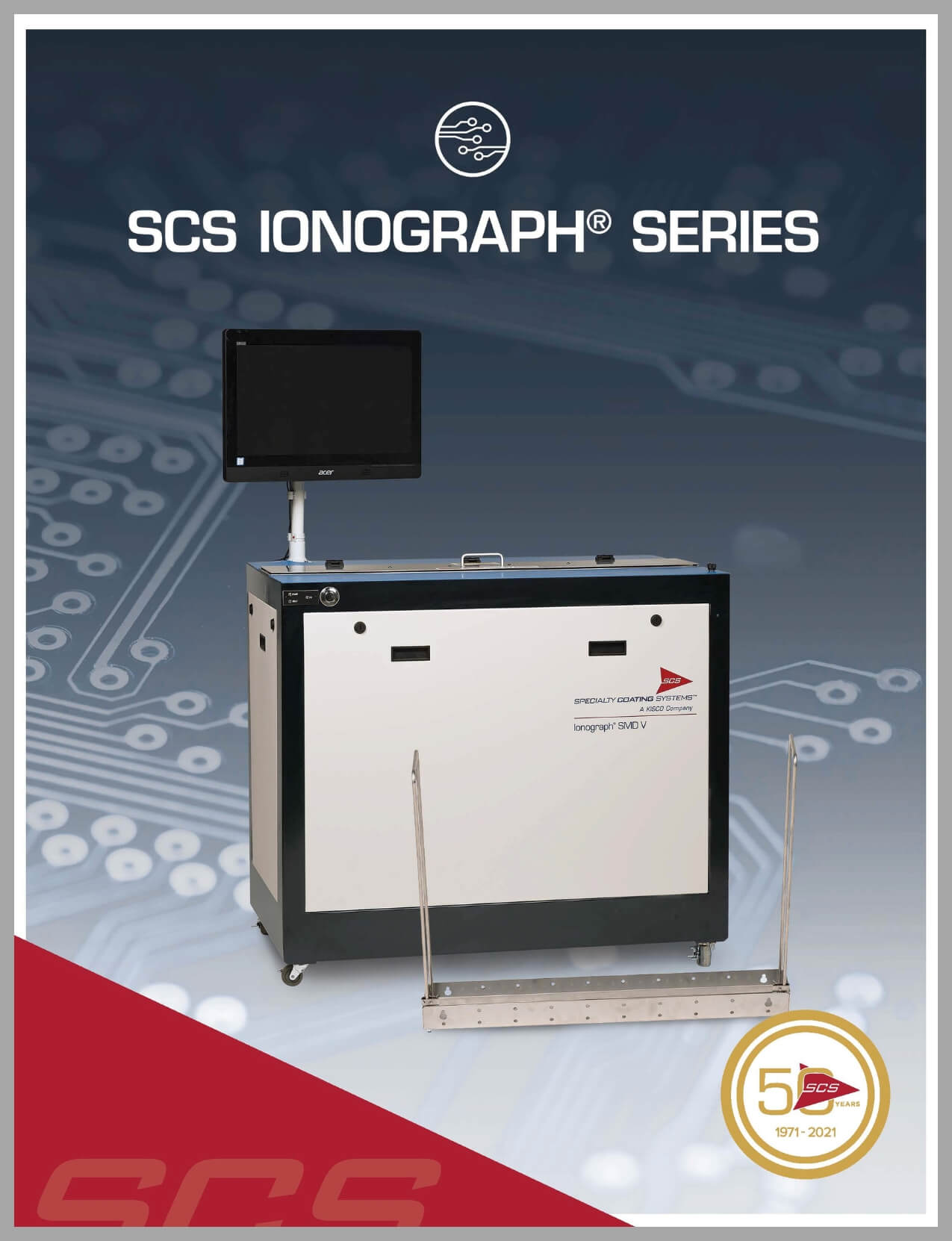

Ionograph® SMD V

Dynamic testing of ionic contamination is a widely approved and followed standard. So, too, is the equipment that makes it possible — SCS Ionograph®. Available in different models, the SCS Ionograph is the industry standard of testing technology.

Product Information

The SCS Ionograph® is the industry standard for ionic contamination testing specified in commonly used cleaning standards. Using the “dynamic” testing method, this line gives you a reliable testing solution at an affordable price. Plus, the SCS Ionograph series is available in four newly redesigned models – the Ionograph SMD V and bench top modules for small, standard and large parts — all operated by our advanced SCS PowerView™ software.

SCS Ionographs offer customers reliable and efficient testing capabilities, including:

- Compliance with industry specifications including MIL-STD-2000A, IPC-TM-650 and ANSI/J-STD-001

- Control of aqueous and semi-aqueous cleaning processes for bare and assembled printed circuit boards

- Control of both the cleaning and the no-clean processes

- Testing to prevent corrosion or product performance problems associated with ionic contamination

- Cleanliness testing of performance-sensitive small parts

- Cleanliness testing of cleanroom specific products such as gloves, fixtures, assembly tools and critical assembly components used in precise manufacturing

- Process control of no clean/low residue processes, including spray fluxer set up and monitoring

SCS Ionograph SMD V Features

- Designed for large part ionic contamination testing in a production environment

- Submerged agitation jets and optional heated extract solution provide outstanding sensitivity

- Available with convenient onboard all-in-one computer or tablet

- Operated with SCS PowerView software

- Test cells available in four test cell sizes

About heated solution testing.

The SMD V gives you the option to test with a heated solution. As IPC-TM-650 describes the benefit, testing with heated solution enables you to “accelerate and improve the efficiency of extraction of ionic material from poorly accessible regions, such as under surface-mounted components.”

Specifications