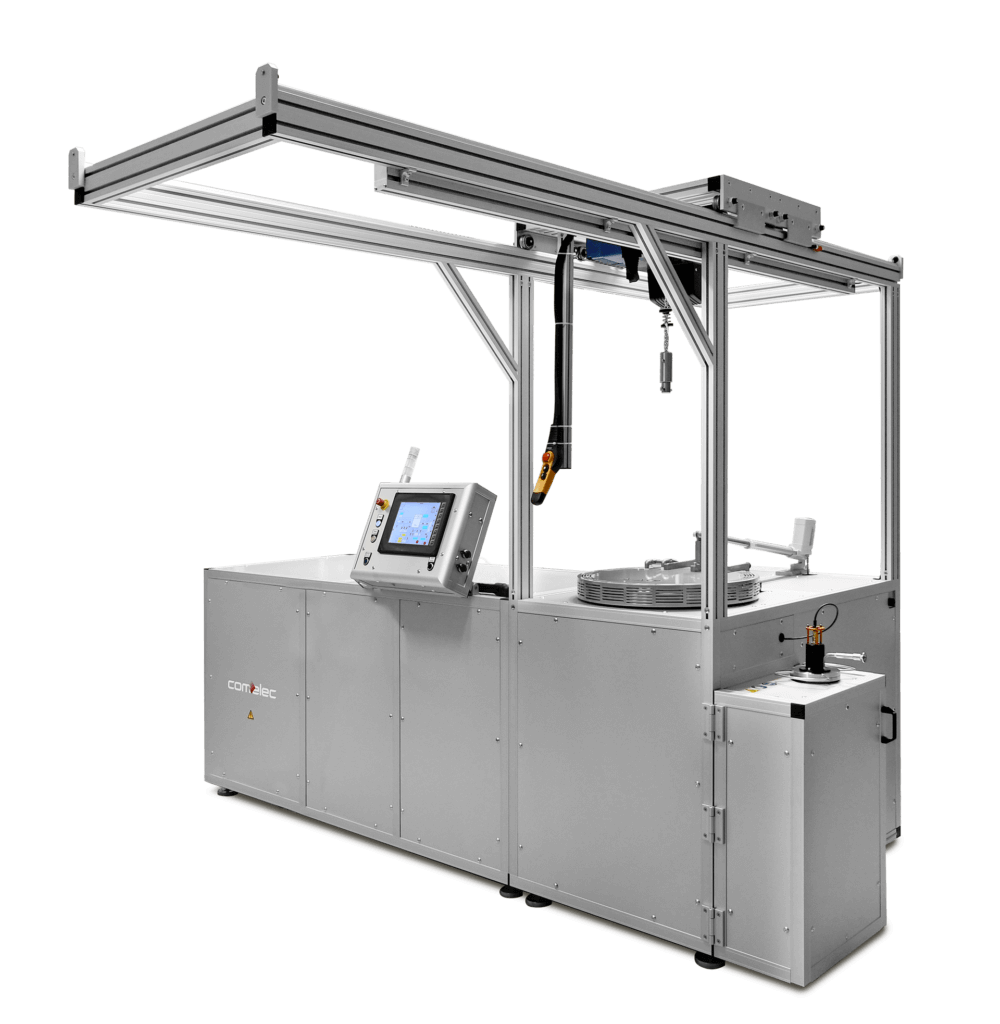

PARYLENE DEPOSITON SYSTEM

Comelec C50S

The Comelec C50S is designed for Parylene conformal coating application in large-scale industrial production settings.

Product Information

When precise and efficient Parylene deposition equipment is needed for high-volume industrial production, the Comelec C50S ensures reliable and stable coating processes. A fully automated system with three configurable levels of user control offers a customizable operating experience. Its features and processing capabilities make it ideal for applying Parylene conformal coatings on small and medium-sized components.

To ensure the highest quality films are created, Parylene coating deposition requires a clean, contaminant-free setting that is temperature-controlled. The Comelec C50S supports these requirements by featuring a double-walled vacuum chamber that minimizes particulate contamination around the door of the chamber while circulating water to guarantee temperature regulation.

System Features

- Thermalized chamber with double-wall technology

- Patented low-contamination door

- Fully automated process with user-configurable operation parameters

- Remote access interface using a standard browser

- Simplified maintenance design with improved access to key areas

- CE certified

Optional Features

- Clean room installation

- Bar code placement for traceability

- Advanced interface and web user experience

- Integrated pulley for tooling placement and removal