Spin Coating Systems

Multi-Dispense System

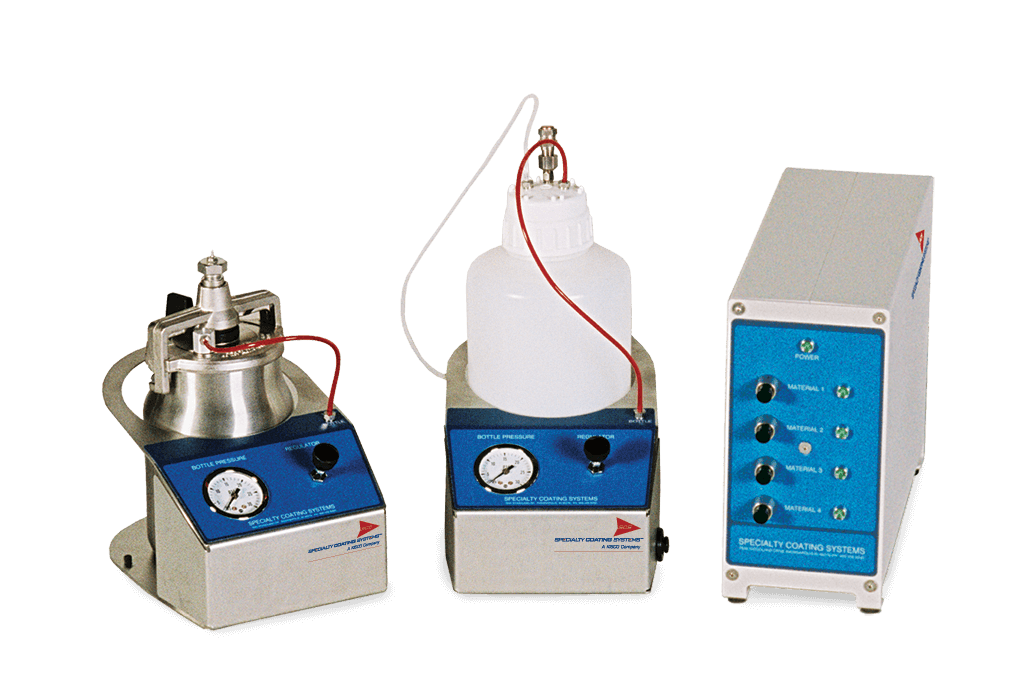

When more than one material is part of a coating application, one name delivers consistent performance. SCS Multi-Dispense gives you four dispense modules to make the coating application and development process even more efficient.

Product Information

SCS’s Multi-Dispense allows users to dispense up to four liquid materials to an SCS spin coater (three with the use of N2). Materials can include coatings, solvents and cleaning solutions, in addition to the N2, which can be used for blow-off or drying. The Multi-Dispense eliminates the need for time-consuming cleaning and change-over, while providing accurate and controlled dispensing of coatings that you have come to expect from SCS.

Specifications

Control Unit

Power

Powered by SCS Spin Coater

Controls

Operated by SCS Spin Coater

Module Capacity

4

Nitrogen supply

30 psi/2.1 bar, >1 cfm/0.472 L/s

Weight

Weight: 5 lb/2.3 kg

Dispense Module – Stainless Steel

Capacity

1 qt (0.95 L) - per module

Container type

Stainless steel

Control type

Pneumatically controlled material valve

Maximum pressure

15 psi/1.034 bar

Needle (valve)

Various sizes available

Port

Luer lock needle port

Dispense Module - HDPE

Capacity

2.1 qt (2 L)

Container type

HDPE

Control type

Pneumatically controlled material valve

Maximum Pressure

5 psi/0.344 bar

Needle (valve)

Various sizes available

Port

Luer lock needle port

SCS G4 Spin Coater Series

The SCS G4 Spin Coater series sets the standard in operating precision and programming flexibility, with a high level of rotation accuracy and repeatability along with precise acceleration and deceleration control.