<< Back to News

SCS Announces Conformal Coating Line-up for APEX

(Indianapolis, IN) – Specialty Coating Systems (SCS) is pleased to announce plans to exhibit in Booth #2307 at the 2018 IPC APEX EXPO, scheduled to take place Feb. 27 – March 1, 2018 at the San Diego Convention Center. The company will showcase its conformal coating line up, including the PrecisionCoat V, PrecisionCoat BT, Omegameter SMD 650 and Parylene coating services.

The PrecisionCoat V, available in conformal coating, dispensing and/or potting platforms, offers maximum flexibility and efficiency for manufacturers. The SCS PrecisionCoat V’s conformal coating and dispense valves move smoothly along the three axis system, with an option to add fully programmable fourth and fifth axes for tilt and rotation capabilities. The system’s multi-valve technology allows for the application of dots, lines, fills, glob tops and spray coat areas; it is a total system solution that ensures accuracy, repeatability and high throughput for a wide range of automated material application, all in a footprint that maximizes valuable production floor space.

Additionally, the SCS PrecisionCoat Automatic Tool Change feature will be available for demonstration on the PrecisionCoat V platform. This feature makes it easy to quickly pick up the active valve or tool, then drop it off and pick up another. This can be performed with up to five valves within the same program with no operator intervention, while maintaining the unit’s large work area.

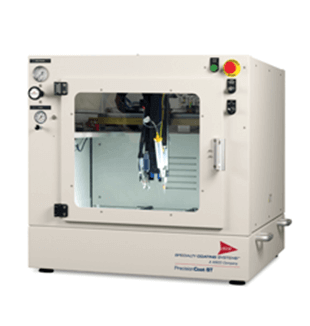

SCS’ new PrecisionCoat BT applies materials via configurable conformal coating and/or dispense valves (up to two) that move along three axes (x, y and z) with a command accuracy of ±0.0001″ (0.003 mm) and ±0.003″ (0.08 mm) repeatability. The system is ideal for manufacturers looking to automate their manual processes and/or add additional capacity to their production floor or lab.

The Omegameter SMD 650 is a next-generation, software-controlled Omegameter cleanliness test system. The system identifies the presence of ionic contamination on bare and assembled printed circuit boards and other electronic components, and provides an accurate and repeatable method for determining cleanliness on location. It complies with current industrial specifications such as ANSI/J-STD-001 and IPC-TM-650, and obsolete military specifications, e.g. MIL-STD-2000A.

Finally, SCS will be showcasing its Parylene coating services and technologies at APEX. With 20 coating facilities around the world and more than 45 years of applications experience in the electronics, automotive, medical device and defense industries, SCS is the global leader in Parylene conformal coating services and technologies.

For more information about SCS, these products or to set-up a booth meeting at APEX, contact SCS at +1.317.244.1200 or visit www.scsequip.com.

About Specialty Coating Systems

With over 45 years of experience and locations around the world, Specialty Coating Systems is the global leader in Parylene conformal coatings and technologies. This extensive coating and application experience is leveraged on each and every customer project, including the industry-leading systems that SCS designs and manufactures. From conformal coating, dispensing and cure systems to ionic contamination test systems, SCS equipment is used in environments that range from university and research labs to high-volume production facilities. SCS’ proactive approach to production and quality requirements-testing, validating, documenting and processing-enables customers and their advanced technologies to meet the most challenging industry specifications and quality requirements. For more information on SCS, visit www.scscoatings.com.