<< View SCS Blog

Thermal Characterization of Parylene for Medical Applications

As medical technologies advance into next-generation life-saving devices, it is imperative that engineers ensure the correct materials are used for the components and assemblies that make up these devices. They must consider a material’s capabilities, including physical properties, biocompatibility and thermal properties, along with the environmental conditions in which the device will be used and necessary manufacturing processes. Parylene conformal coatings are commonly used to protect life-saving medical devices, providing exceptional thermal properties that are critical to their performance and reliability. This article explores the evaluation of Parylene’s thermal properties.

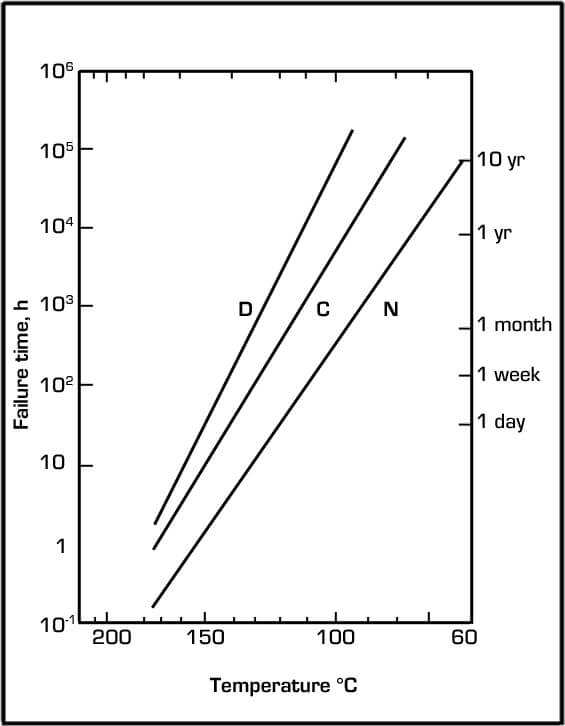

Continuous Exposure

Parylene survivability to higher-temperature exposure for 24 hours and 10 years has traditionally been based on an evaluation found in the Kirk-Othmer Encyclopedia of Chemical Technology.1 The resulting chart in Figure 1 shows data for Parylenes N, C and D. This method is rather complex, plotting failure points of tensile test specimens as the log of time versus temperature, further requiring an extrapolation out to 10 years of service. This data is best suited for evaluating continuous exposure to elevated temperatures and is difficult to use to accurately predict short-term thermal exposures.

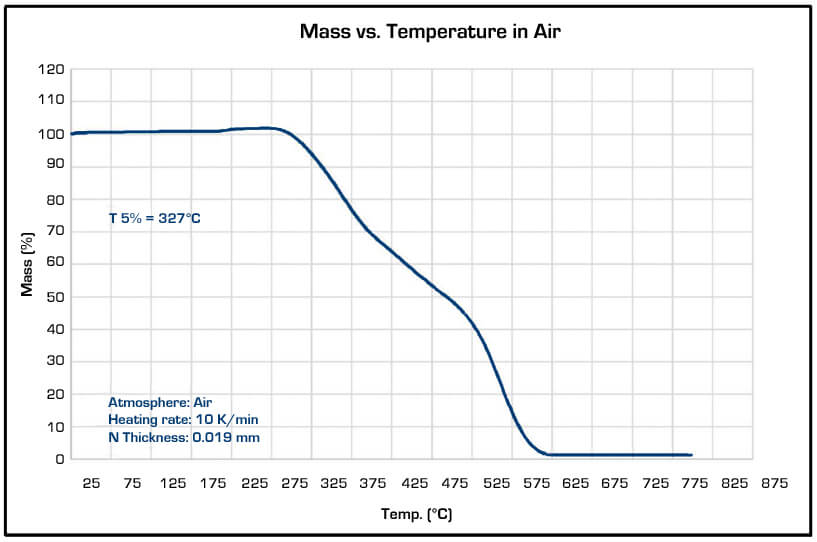

Thermogravimetric Analysis (TGA)

For heating processes that last seconds, minutes or hours, a more applicable method of determining thermal suitability is vital. Thermogravimetric analysis, also known as TGA, is an improved predictor of short-term thermal endurance and is the industry standard for evaluating thermal behavior of polymer materials. TGA is conducted by constantly weighing the test sample while heating it in a precisely controlled manner. The resulting graph simply plots the sample mass vs. temperature and clearly illustrates thermal limits of the tested material.

Figure 2 shows the TGA analysis of Parylene N in air, an oxygen-containing environment. The value marked as T5% is a common point used in polymer evaluations to describe the onset of thermal decomposition and is defined as the temperature corresponding to a mass loss of 5%. This is not specifically a failure point, but since it provides a general indication of material survivability, it is a reference point that can be used to compare competing materials. When the environment is air, the T5% value for Parylene N is 327°C. TGA testing has also been conducted in a nitrogen environment (oxygen-free) and, as expected, thermal endurance of Parylene N improves significantly with a T5% value of 480°C. Engineers have many parameters to consider from a materials and design standpoint. TGA can be a tool to better understand temperature-related concerns. Once the environment and expected temperature swings have been defined, a prediction can be made regarding the suitability of a given polymer.

To learn more about Parylene’s thermal properties and how it can benefit your next-generation medical application, contact SCS.

1. Kirk-Othmer Encyclopedia of Chemical Technology, John Wiley & Sons, Inc., Jan. 26, 2001.

Global Coverage Issue 101, Winter 2025