<< View SCS Blog

SCS PrecisionCoat Valve Options Provide Precise Material Application

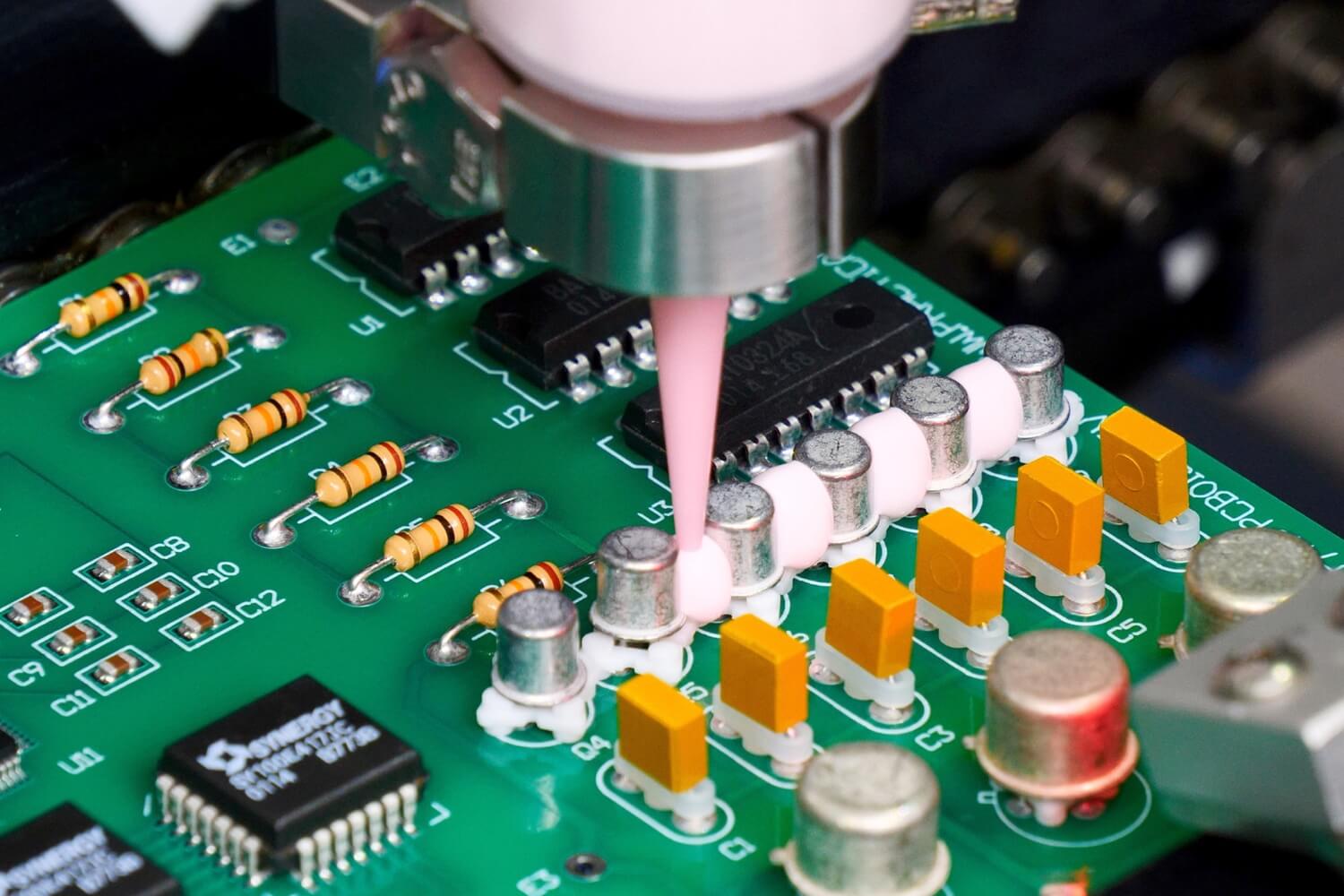

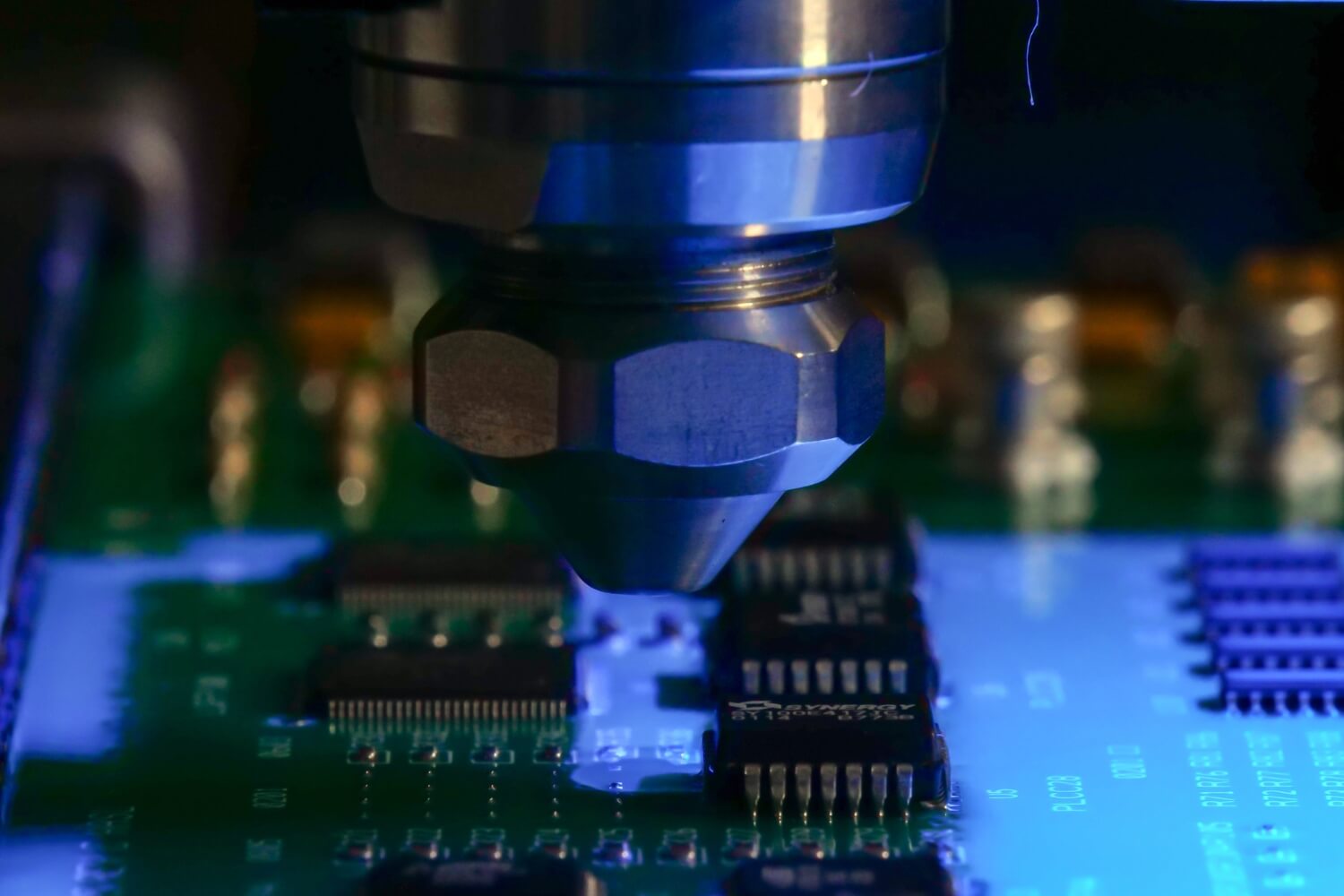

The SCS PrecisionCoat VI selective conformal coating and dispense system is a robust and fully programmable, multi-purpose system. The PrecisionCoat offers unparalleled programming for efficiency in automated material applications, featuring advanced valves designed for exceptional material handling in a modular configuration. These valves enhance the PrecisionCoat’s flexibility, allowing for the application of a wide range of conformal coating materials such as silicones, acrylics, urethanes, epoxies and more.

Spray valves are available in an assortment of sizes, including micro spray for precise coverage in small areas and wide area spray which is designed for larger areas. For added control, the SCS spray valve goes above and beyond traditional designs by integrating custom spacers to “micro” adjust the space between the air cap and material nozzle, allowing for greater variation and control of the spray pattern and edge definition.

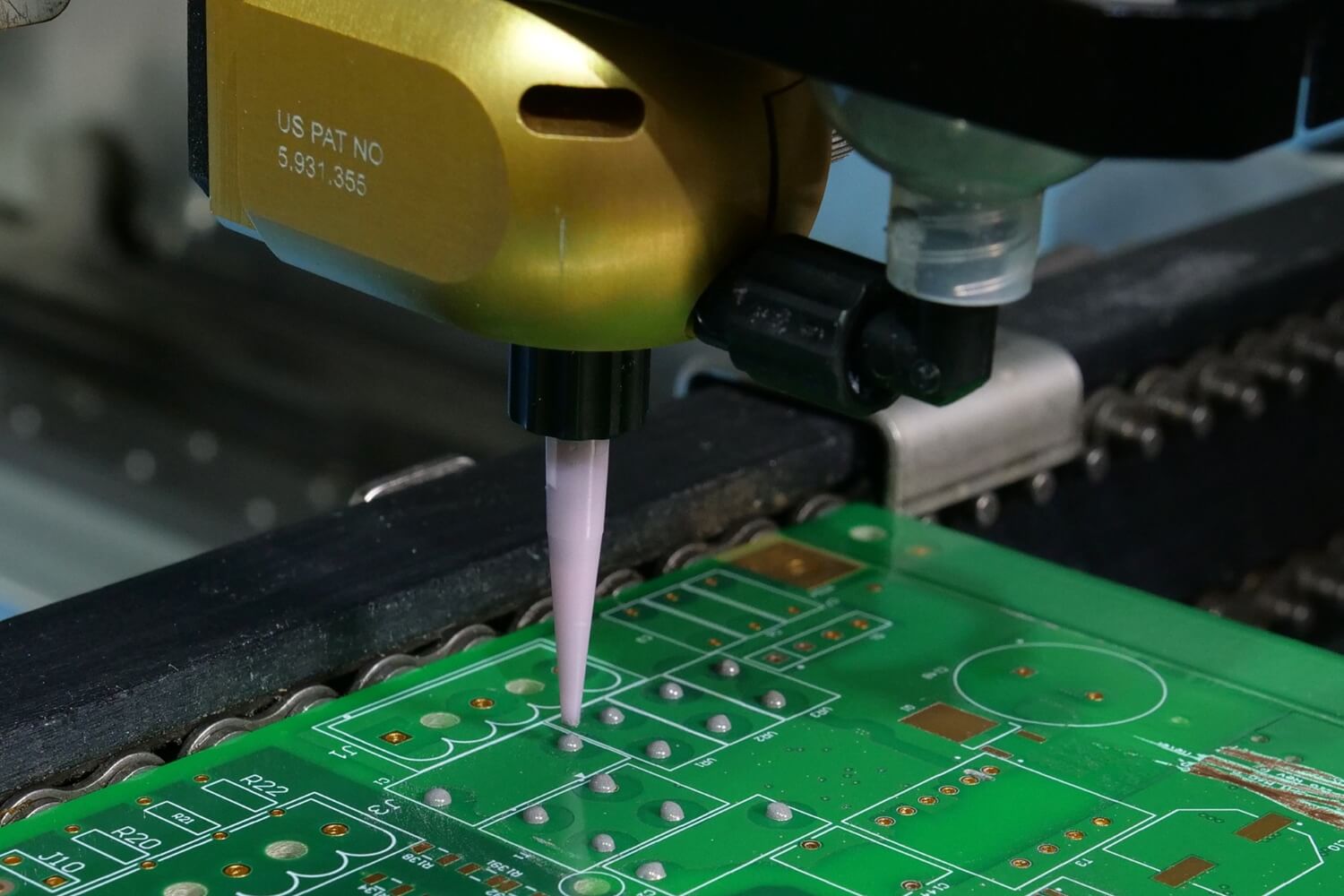

Dispense valves, such as needle dispense, micro dot and jet valves, offer accurate edge definition and flexibility when coating near sensitive components or critical areas. The SCS tower jet valve provides no-contact dispensing of coatings with measured volumes and repeatability. This is achieved through fully-programmable piezo elements, ensuring repeatable and flexible options for users. To ensure accurate dispensing, SCS valves incorporate a micrometer for needle positioning to precisely control material flow after maintenance.

When working with higher viscosity materials, such as RTV and adhesives, auger valves or spool valves are ideal for achieving accurate dispense volumes. Spool valves dispense liquids through specific needles that can cycle on/off, ensuring a clean cut-off of material by drawing back material at the end of the dispensed pattern; auger valves can dispense higher viscosity materials at measured rates.

Potting involves dispensing materials to seal, stabilize and/or protect applications from shock, vibration, moisture or corrosion. It is a form of dispensing that often utilizes two-part materials mixed together by a static mixer and a pumping system that allows for programmable ratios. In potting applications with higher viscosities, a piston valve controls material output, while progressive cavity pumps provide flexibility with a user-defined ratio and output.

The PrecisionCoat’s highly-flexible design and advanced valves provide unmatched versatility and control for a wide range of conformal coating applications. Whether using spray, dispense or potting techniques, users can achieve the optimal material handling and repeatability necessary to ensure the success of their specific application.

To learn more about the SCS PrecisionCoat VI and its advanced valves, visit scsequip.com or contact SCS.

Global Coverage Issue 99, Summer 2024