<< View SCS Blog

New SCS PrecisionCure UVC (MUV) Provides Unparalleled Control over the Curing Process

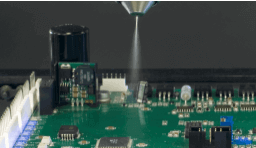

SCS recently introduced a new curing system – the PrecisionCure UVC with microwave UV curing technology. With programmable curing profiles and the smallest footprint in the industry to maximize valuable production floor space, the innovative curing system provides customers with the flexibility needed to take their manufacturing operation to the next level.

The PrecisionCure UVC (MUV) features a patent-pending lamp movement trolley that moves lamp(s) over the product via the horizontal axis. This movement is counter to standard curing processes where the board moves on a conveyor under a fixed lamp. In addition, users can customize each profile to vary the dosage of UV exposure on different components of a single board. The PrecisionCure UVC’s advanced lamp travel technology coupled with programmable curing profiles provide users with unparalleled control over the curing process.

Utilizing Heraeus Noblelight® microwave-activated UV lamps, the industry standard in microwave UV curing technology, the SCS cure system is available in single, double and triple lamp configurations and can operate as a stand-alone machine or as a compliment to SCS PrecisionCoat selective conformal coating and dispense systems. The PrecisionCure UVC (MUV) features Windows®-based software with a touchscreen monitor and is designed for continuous operation, minimizing required downtime for maintenance.

To learn more about the PrecisionCure UVC (MUV), visit scsequip.com or contact Hans Bok at 508.997.4136 or hbok@scscoatings.com.

Global Coverage Issue 91, Spring 2022