<< View SCS Blog

Conformal Coatings Provide Barrier Protection to Batteries Across Markets

The environments in which batteries are being used are continuously evolving. Due to the rapid advancement of the technology, battery usage is growing at an exponential rate. Many medical implantable devices, drones, stationary energy storage, advanced defense and aerospace technologies and hearables depend on batteries for successful operation. As new applications for batteries are being developed, more environmental operating challenges are expected to occur.

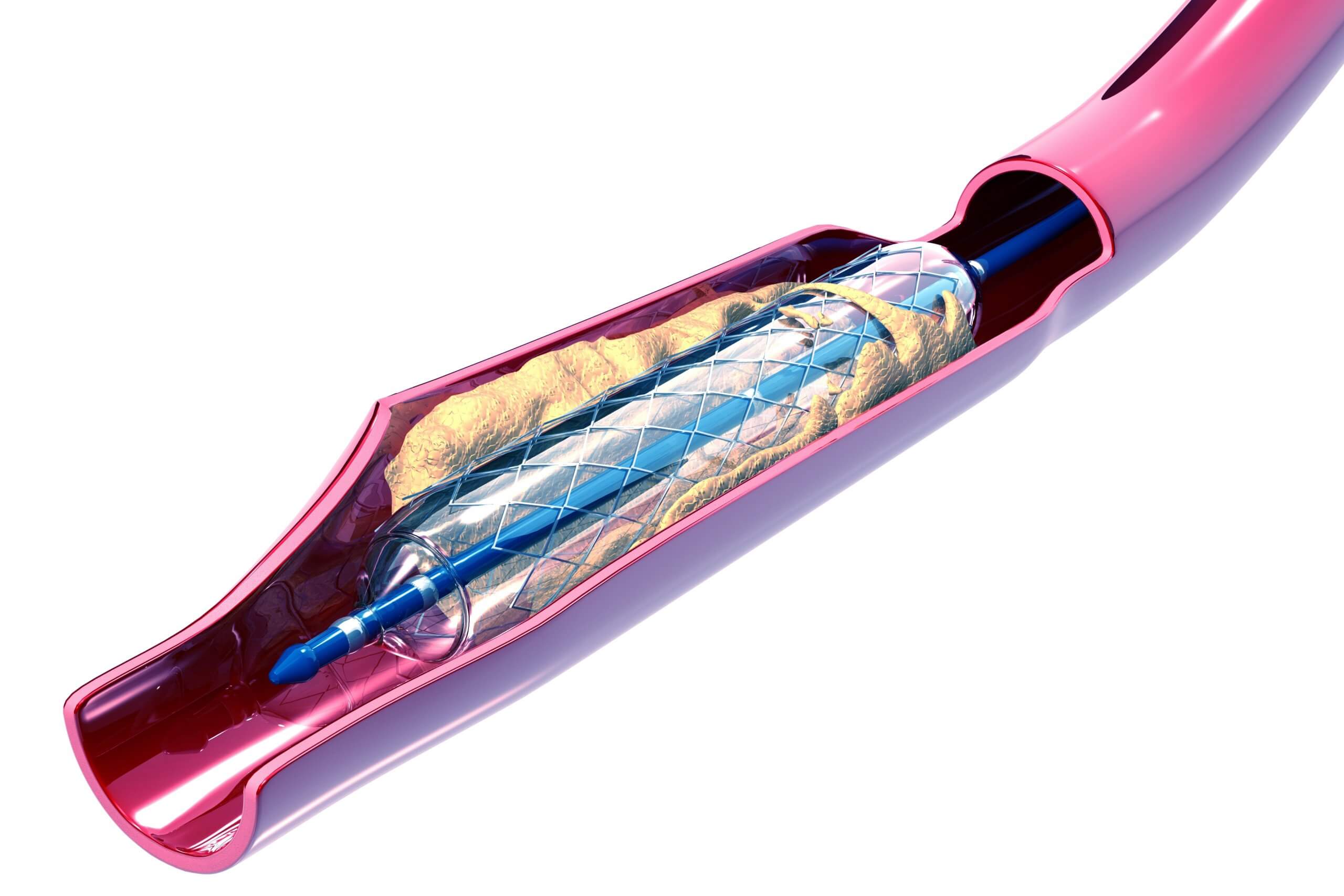

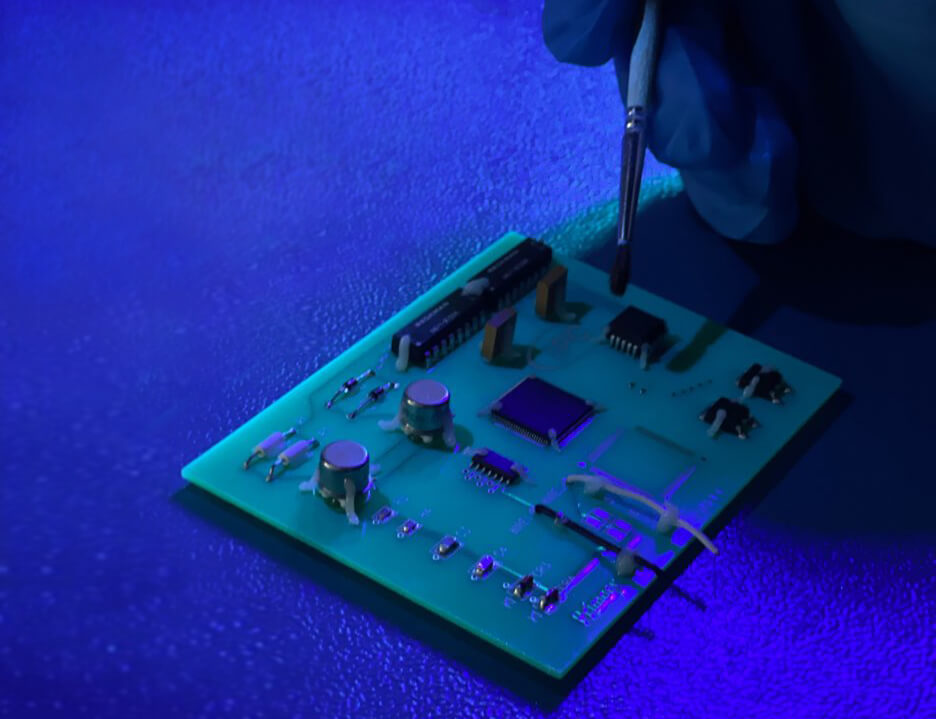

Batteries come in all shapes, sizes and designs as well as different materials, from lithium to solid-state, with the most common types being coin, button, pouch, solid-state and rolled. Of these, coin, button and solid-state most benefit from the application of conformal coatings directly to the battery; they come in small sizes and are utilized in applications like hearables, medical implantable devices and hearing aids that are regularly exposed to sweat, moisture and corrosive fluids. Conformal coatings, such as Parylene and PlasmaGuard™, provide thin-film barrier protection on the surface of batteries to safeguard them from environmental factors. More importantly, conformal coatings prevent the batteries from corrosion, maximizing their life.

Other batteries, such as pouch and rolled batteries, typically do not utilize conformal coating directly on the battery, but they do require a form of barrier protection to improve efficiency. Pouch batteries are often used in automotive, consumer and military applications. With the battery components enclosed, the pouch acts as the protective barrier. Rolled batteries are commonly used in commercial and industrial applications and are installed in large arrays that are often filled with a potting or encapsulation material.

As new battery technologies and applications emerge, providing batteries with the necessary level of protection to ensure they perform reliably throughout their expected operational life will remain essential. Conformal coatings play a crucial role in engineering a robust battery across all markets, and as the demand for smaller, high-density batteries increases, coatings are well-suited to meet environmental challenges that may arise.

For more information on conformal coatings and how they provide the critical moisture barrier needed for the batteries used in your application, contact SCS online or call +1.317.244.1200.

Global Coverage Issue 96, Fall 2023