SCS Blog

Recent SCS Blogs

Drawbacks of Parylene Coating

Parylene has a well-deserved reputation as one of the leading choices for conformal coatings. For many applications, it is the best choice. However, there are some Parylene disadvantages as well. Coating Cost and Logistics A major downside of Parylene is its cost. The Parylene dimer used for coating varies in price and is usually purchased by the pound.... Read More >>

Conformal Coating Specifications: Guidelines for Design, Selection and Application of Conformal Coatings

Understanding the unique characteristics of different conformal coating types and how they interact with a wide range of products and materials is crucial for achieving optimal functionality, performance reliability, and product longevity. Designers and users of conformal coatings need to understand the distinct properties of each type and their compatibility with the components they protect,... Read More >>

The Importance of Cleanliness Testing

Successful conformal coating relies on ensuring the surface of the printed circuit board (PCB) is thoroughly clean prior to coating application. PCB contamination can cause critical degradation of coatings’ dielectric strength and insulation resistance. Cleanliness testing monitors the PCBs condition, assuring it is sufficiently free of contaminants and ready to accept conformal coating. Cleaning before... Read More >>

SCS Celebrates 50 Years of Innovation and Leadership

SCS is proud to announce the celebration of its 50th anniversary. As the direct descendant of the companies that originally developed Parylene and made it a commercial success, SCS has established a legacy of innovation and leadership in the conformal coatings industry. In 1971, Nova Tran Corporation was established in Clear Lake, Wisconsin, after... Read More >>

SCS Expands Solutions Portfolio to include Liquid Coatings

With the acquisition of Diamond-MT (DMT) in March, SCS is pleased to expand its coatings portfolio to include liquid coating services. Liquid coatings, including acrylics, silicones, urethanes, epoxies and ultrathin coatings, are currently being serviced through the company’s facilities in Johnstown, Pennsylvania, and Melbourne, Florida. These facilities are ISO 9001:2015 and AS9100 Rev. D certified... Read More >>

Parylene’s Critical Role in Hayabusa2 Space Mission

In December 2014, the Hayabusa2 spacecraft, designed and operated by the Japan Aerospace Exploration Agency (JAXA), was launched from Tanegashima Space Center in Japan. Its mission was, and is, to travel to the asteroid Ryugu, collect samples from the surface and interior of the asteroid and return those samples to earth. Following its successful launch,... Read More >>

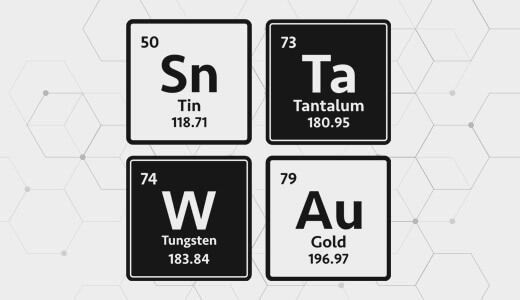

SCS Complies with Conflict Mineral Regulations

One of the common inquiries SCS receives is in regard to conflict mineral regulations. These regulations are part of an international effort to reduce the trade of resources that could finance armed groups in politically unstable areas and fuel forced labor and other human rights abuses. The regulations cover minerals and metals known as 3TG... Read More >>

Conformal Coatings “Quietly” Meet the Needs of the Electric Vehicle Market

As the world transitions toward electric vehicles (EV) and a reduced carbon footprint, SCS is playing an active role in supporting the market’s current and future growth. As alluded to in its name, electric vehicles are full of electronics, and those advanced electronics and components require increased protection. Conformal coatings are a silent partner in... Read More >>

SCS Introduced PrecisionCoat VI at Assembly Show

SCS is pleased to announce the introduction of its new machine platform for coating and dispensing, the PrecisionCoat VI. The PrecisionCoat VI debuted at The Assembly Show, which took place October 26-28, 2021, in Rosemont, Illinois. SCS offered live demonstrations of the system in their booth. Building upon the outstanding reliability and precision of its... Read More >>

Removing Conformal Coatings

Conformal coatings provide a long-term, stable and reliable encapsulation method for the electronic components from environmental effects. Different industries and service conditions call for different protective coatings. In some cases, changes in the requirements or mistakes would call for action to remove the coating. While some coating materials are easily removed, some are virtually impossible... Read More >>