SCS Blog

Recent SCS Blogs

A Guide to Parylene Service Temperatures

A specialized chemical vapor deposition (CVD) process adheres Parylene conformal coatings to substrates. CVD uniformly encapsulates all exposed substrate surfaces as a gaseous monomer; completely eliminating wet coatings’ liquid phase and need for post-deposition curing. Synthesizing in-process, CVD polymerization requires careful monitoring of temperature levels throughout. Beneficial thermal properties of Parylene protective coatings include reliable... Read More >>

Benefits of Conformal Coatings for LEDs

LEDs are often subjected to harsh environments. To ensure that they perform reliably long term in these conditions, LEDs often rely on conformal coatings. Below are the three coatings commonly considered to protect LEDs: Parylenes: Parylenes are often selected due to their ultra-thin, optically clear nature and resistance to moisture and chemicals. Designed for harsh... Read More >>

Conformal Coating for Agricultural Lighting

Used for food production, indoor gardening and hydroponics and horticulture, grow lights have both industrial and consumer applications. Because total illumination intensity diminishes with distance from the point source (grow lightbulbs), production efficiency is enhanced by: The objective is equal lighting, with the entire range of generated illumination shining on plants. Where direct light is... Read More >>

Can Parylene be used as a Standalone Enclosure?

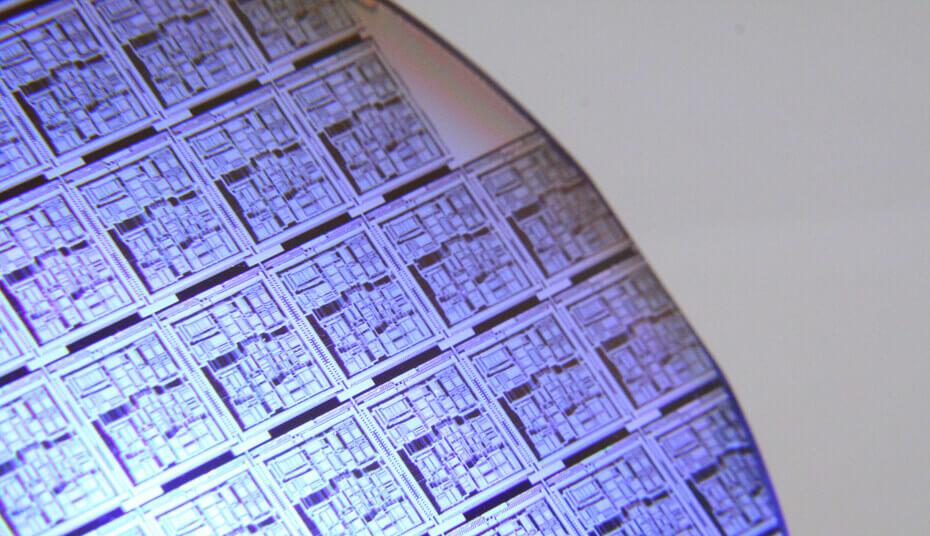

Parylene polymer conformal films are recognized for their wide array of advantageous functional traits when it comes to coating printed circuit boards (PCBs) and similar electronics. These films offer valuable properties like biocompatibility, resistance to chemicals and solvents, reliable dielectric and insulation characteristics, and ultra-thin, pinhole-free film thicknesses ranging from 1 to 50 μm. Furthermore,... Read More >>

Types of Parylene

Applied in a gaseous form to component surfaces through a chemical vapor deposition (CVD) process, Parylene (Poly-para-xylylene) films protect printed circuit boards (PCBs) and similar electrical assemblies. Gaseous CVD application supports efficient coating of complex component surfaces characterized by crevices, exposed internal areas, or sharp edges. Depending on the specific use, Parylene conformal coatings exhibit... Read More >>

When to Use Conformal Coating Removal Services

If necessary, it is possible to remove unwanted conformal coatings from PCBs. The process can often be accomplished by either the assembly’s original equipment manufacturer (OEM) or an end-user, but the capability to do so does not always exist. For these parties, removing the coating may be beyond the purview of their experience with conformal... Read More >>

Parylene vs Acrylic Conformal Coatings

Parylene and acrylic resins serve as conformal coatings, yet their similarities are limited. Due to their distinct properties, each possesses unique uses and capabilities. Application Acrylic conformal coatings, a type of liquid conformal coating, can be applied in four ways: by spray, dip, brush or robotics. The chosen method depends on several factors, such as... Read More >>

Parylene and Wearable Devices

Wearables are no longer an emerging technology — they are here. Whether a wearable is a medical device like an insulin pump, a smart watch or even a finely woven piece of smart fabric, they all have one basic fact in common. All of them contain technologies that need protection from the outside world, and... Read More >>

Benefits of Parylene Coatings for Electronics

Parylene conformal coatings are some of the best protection options available for printed circuit boards, multi-layer assemblies and other electronics. The coatings are applied through a vapor phase deposition (VPD) process that transforms the solid Parylene raw material, known as dimer, into a gas, enabling complete coverage of the substrate’s surface including deep penetration into... Read More >>

Properties of Acrylic Conformal Coating

Exceptionally user-friendly, liquid acrylic resin (AR) conformal coatings protect printed circuit boards (PCBs) and similar electronics from corrosion, dirt/dust, fungus, moisture and thermal shock. AR’s ease of application contributes to its status as the most frequently used conformal material. Liquid Application Methods for AR The primary means of AR liquid application are brush, dip (immersion)... Read More >>