SCS Blog

Recent SCS Blogs

Typical Conformal Coatings Use

Different conformal coatings have a wide range of uses throughout many different industries. While originally applied within the electronics industry, conformal coatings many benefits have led to its use in many other fields, most notably medical, aerospace and defense and automotive. Medical While all conformal coating types can be used for different applications, Parylene is the... Read More >>

Nonconformity of Parylene on Wafers

The polymer Parylene (XY) provides exemplary, ultra-thin conformal coating for printed circuit boards (PCBs), solar cells, light emitting diodes (LEDs), medical implants, aeronautical/military equipment and numerous other products, with uniform, insulative protection in the nanometer range. One of XY’s basic advantages is its reliable coating uniformity, exceeding that of liquid materials like acrylic, epoxy, silicone... Read More >>

Things to Consider when Choosing a Parylene Coating Service Provider

The Parylene coating industry is a fairly niche business, but it is still a competitive market. However, the few top-quality providers are relatively easy to identify. Here are some of the attributes that you should actively seek when searching for a Parylene conformal coating provider: Liquid Coating Capabilities While it might seem counterintuitive, look for... Read More >>

What Temperature is Parylene Applied at?

Parylene (XY) conformal coatings are applied to substrate materials through a specialized vapor deposition polymerization (VDP) process that completely eliminates the liquid phase of wet coatings. In addition, no initiators or catalysts are involved in VDP, which results in truly conformal protective films. This is in stark contrast to wet coating materials such as acrylic,... Read More >>

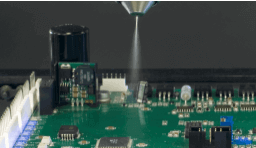

Conformal Coating Types: Acrylic, Urethane, Silicone and Parylene

Conformal coatings, utilized in aerospace, automotive, commercial, defense, industrial, and medical sectors, are applied as thin film layers typically ranging from 5 to 130 microns or 0.0002 to 0.0051 inches. Their remarkable thinness is a key attribute. These coatings protect printed circuit boards (PCBs) and other electronics from operational issues caused by unintended contact with:... Read More >>

Can I Solder Through Parylene?

Parylene: Properties and Processes Conformal coatings are applied to printed circuit boards (PCBs) and other sensitive electronics to protect their components and electrical function. Parylene conformal coatings provide these assemblies superb security from electrostatic discharge, and additional performance advantages, including: These characteristics are adaptable to a wide range of as aerospace, defense, automotive, consumer, industrial... Read More >>

How Parylene Cost is Determined

Parylene is frequently considered one of the pricier choices for conformal coatings. A brief examination of cost components quickly reveals the rationale behind this. The primary cost determinants for Parylene include raw materials, labor and lot volume. Raw Materials – Parylene Dimer and Adhesion Promotion Parylene dimer serves as the foundational material for Parylene, entering... Read More >>

SCS Welcomes Switzerland-based Comelec SA

Specialty Coating Systems (SCS) recently announced the acquisition of Comelec SA., a strong and established provider of Parylene, Atomic Layer Deposition (ALD) and multilayer coating services, equipment and raw materials. Located in La Chaux-de-Fonds, Switzerland, Comelec was established by the Zutter family in 1979 and, like SCS, received one of the first Parylene technology licenses... Read More >>

Parylene Delivers Critical Barrier Protection for Medical Cables

Today’s specialized medical cables are complex components of larger systems used in all phases of preventative, diagnostic and therapeutic medical care. The essential and functional components of a medical cable include high-performance connectors, sheaths or jackets, and conductive lines. To meet and exceed the demanding needs of doctors, nurses and medical technologists, conformal coatings often... Read More >>

Coating Spotlight: SCS Acrylic Conformal Coatings

Defined by IPC-CC-830 as Type AR, acrylic conformal coatings are some of the most widely used coatings in the market today. Acrylic coatings provide strong moisture protection, are generally easy to apply and come at a relatively low cost point. While there are numerous formulations available, a few well known acrylic coatings include HumiSeal® 1B31,... Read More >>