SCS Blog

Recent SCS Blogs

Which Coating Should I Use? Comparing Parylene and Acrylic Conformal Coatings

Parylene and acrylic resins are both well-known conformal coatings. Due to variances in their chemistries, each family of coatings has their own unique properties, uses and capabilities. Following is a brief review of how Parylene and Acrylic conformal coatings are applied, their advantages and drawbacks, and applications that benefit from each coating. Coating Application Parylenes:... Read More >>

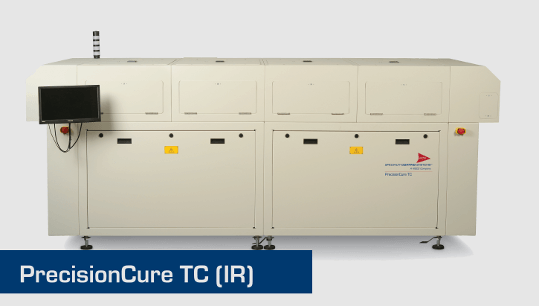

SCS Infrared Radiation Systems Improve Curing Technology

SCS equipment is used in environments that range from university and research labs to high-volume production facilities. SCS’s proactive approach to production and quality requirements – testing, validating, documenting and processing – enables customers and their advanced technologies to meet the most challenging industry specifications and quality requirements. By staying updated on the newest trends... Read More >>

Ruggedizing UAV Electronics with Parylene

Unmanned aerial vehicles (UAVs) are aircraft piloted by remote control or onboard computers. They are an integral element of unmanned aircraft systems (UAS) which consists of three basic components: the UAV, a ground-based controller and a system of communications between the two. Also called drones, UAVs are often used for military missions. The electronic assemblies... Read More >>

What’s the Best Coating for MEMS?

Microelectromechanical systems (MEMS) encompass technologies with operational components sized between 1-100 micrometers. The miniaturization of MEMS devices and structures, including their mechanical and electro-mechanical elements, is a direct result of advancements in adapted semiconductor fabrication technologies initially employed for electronics. MEMS are primarily defined by mechanical functionality, regardless of the components’ physical mobility within their... Read More >>

Parylene Masking: Materials and Methods

Parylene deposition takes place at the molecular level. Applied at room temperature through chemical vapor deposition (CVD), the typical thickness of Parylene conformal film is in the microns-range. Advantages of Parylene coatings include: Despite its benefits, Parylene has some disadvantages. Among these are: A further disadvantage is the need for costly, time-consuming masking of selected... Read More >>

Parylene for Industrial MEMS

In modern industrial applications, sensors play a crucial role in collecting and converting analog data into digital form. The design of sensors for various purposes has become increasingly reliant on microelectromechanical systems (MEMS) technology. MEMS consist of tiny mechanical devices made from semiconductors, often operating by reflecting optical signals between input and output fibers using... Read More >>

Why does the Parylene Process take so Long?

Parylene is a transparent polymer that offers uniform and pinhole-free conformal coatings for printed circuit boards, medical devices and microelectronics. Common Parylene variants available through a modification of the molecular structure of para-xylylene include Parylenes N and C, ParyFree® and Parylene HT®. Each modification results in a slightly differing set of material properties that are... Read More >>

Parylene and MEMS Technology

Parylene’s application as a structural material in microelectromechanical systems (MEMS) devices has garnered notable attention. Parylene C, known for its biocompatibility, is widely used in implantable medical devices. Parylene C is also compatible with MEMS microfabrication processes. What are MEMS? Microelectromechanical systems (MEMS) is the technology of very small devices; it merges at the nano-scale... Read More >>

Common Parylene Defects

While Parylene is an extremely effective conformal coating, applications only benefit when the coating is properly applied. When Parylene is either applied incorrectly or is deposited on a surface that is not prepared for adhesion, the coating can become compromised. Luckily, common Parylene defects can be identified, planned for and mitigated through proper procedures. Problems... Read More >>

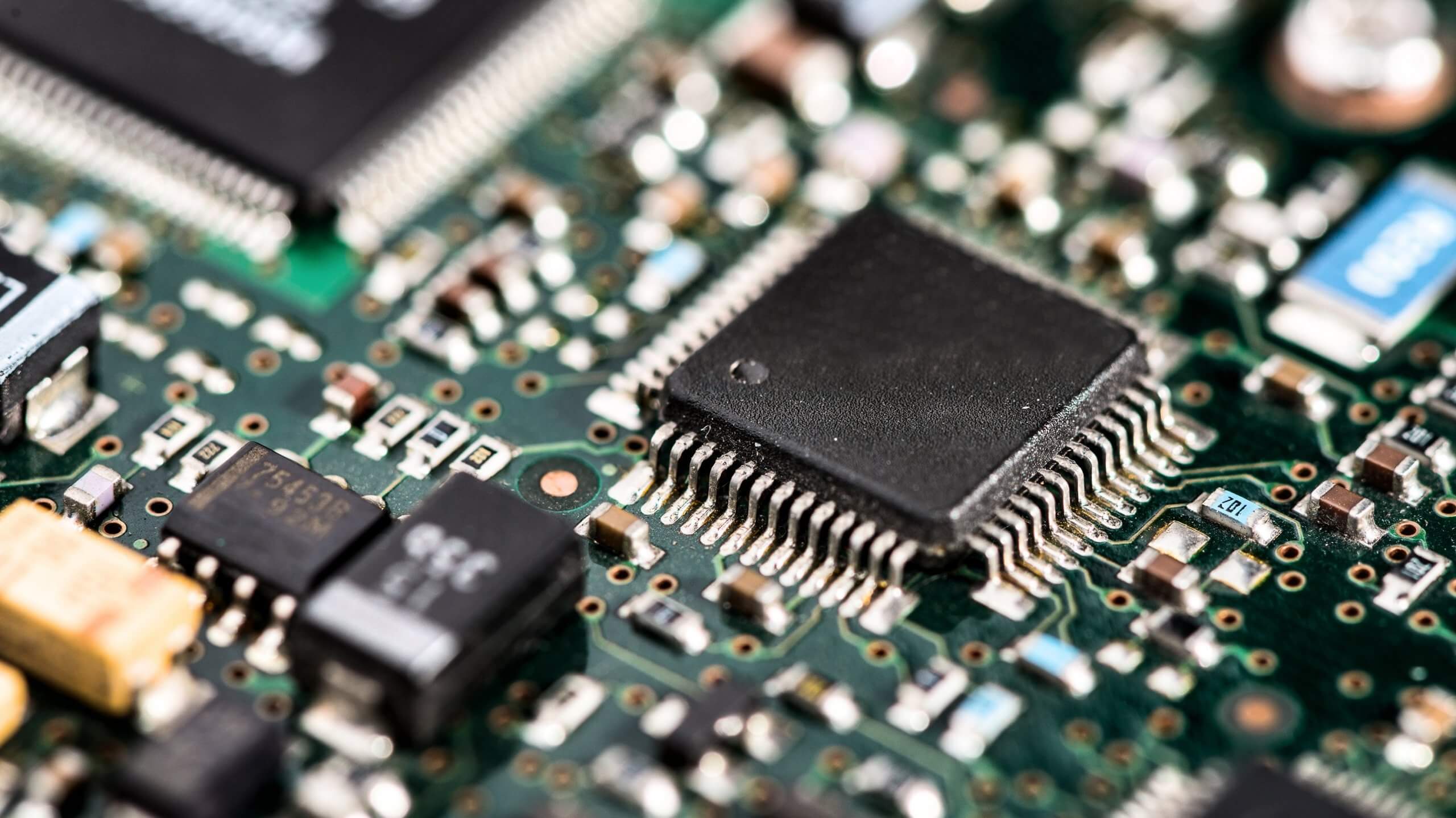

What can be Coated: A Comparison of Liquid and Parylene Coatings

Conformal coatings are used to protect printed circuit boards (PCBs) from dust, humidity/moisture, mildew/mold, temperature cycling and other elements whose prolonged contact might interfere with assembly function. Coatings also enhance electrical clearance-tolerance, while safeguarding PCB components from contamination (particulate or otherwise), corrosive materials, and mechanical stress. The liquid coating materials – acrylic (AR), epoxy (ER),... Read More >>