SCS Blog

Recent SCS Blogs

Can Parylene Be Layered?

Multilayer conformal coatings are advantageous in resolving diffusion or stability issues. A vast amount of knowledge is available in the literature about the use of multilayered stacks of Parylene and stacks making use of different intermediate materials such as ALD, metals and so on. Use of multiple layers of Parylene C was most commonly reported... Read More >>

Parylene Disadvantages

Parylene stands out as the ultimate shield against solvents among conformal coatings. It boasts exceptional defense against moisture and gases, incredibly high dielectric strength and biocompatibility. Despite these advantages, Parylene does come with certain drawbacks compared to other coating options. One of these disadvantages is cost. The cost for Parylene is typically higher than other conformal coatings.... Read More >>

Cracking in Conformal Coating: Major Causes and Preventative Strategies

Conformal coatings protect printed circuit boards (PCBs) and similar electronic components used in a wide range of aerospace, defense, transportation, electronics and medical devices. Coatings effectively cover PCBs, shielding them from contaminants, liquid incursions, temperature fluctuations and other conditions potentially hazardous to component performance. However, problems can develop if preparation, application and drying processes are... Read More >>

Ultraviolet (UV) Stability of Parylene

For all of Parylene’s strengths, it has one key drawback — its resistance to ultraviolet (UV) radiation is limited. Most formulations of Parylene gradually yellow when exposed to the kind of UV light produced by the sun. While this isn’t an issue when Parylene is used to coat a printed circuit board sealed in a box, it... Read More >>

Disadvantages of Using Parylene on Electronics

While Parylene offers various advantages as a conformal coating, it comes with inherent drawbacks that warrant consideration prior to its application. The emergence of failure mechanisms associated with Parylene coatings has limited its wider scale application in comparison to liquid conformal films such as acrylic, epoxy, silicone and urethane. In numerous scenarios, wet coatings may... Read More >>

Does Parylene Prevent Abrasion Damage?

Unlike liquid coatings – acrylic, epoxy, silicone and urethane – Parylene does not use wet method application. It can neither be brushed or sprayed onto substrate surfaces, nor will immersion – soaking the substrate in a bath of coating material – work. Parylene relies on a unique chemical vapor deposition (CVD) method of coating application.... Read More >>

How to Test Parylene Adhesion

The Need for Adhesion Testing Applied mechanical processes stimulate the binding force between surface molecules required for Parylene adhesion to substrates, which is essential to both good Parylene performance and assembly/component functionality. The emergence of conditions characterized by non-adherence and delamination squander the coating’s typically exceptional protection against chemical attack, corrosion and moisture, as well... Read More >>

How to Improve Parylene Adhesion to Noble Metals

Characteristics of Noble Metals Selecting the appropriate pre-treatment procedures is a key factor to this success of Parylene adhesion to any substance. Procedures can vary and are dictated by the substrate to be coated. Chemically inert surfaces like gold, silver and other noble metals, and nonpolar thermoplastics such as Parylene, are extremely difficult to bond... Read More >>

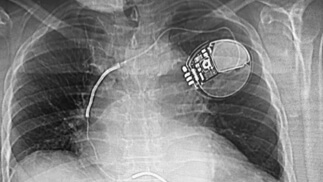

Best Implantable Device Coating

Implantable devices place a special set of requirements and challenges on their coatings. The moisture and broad mixture of chemistries inside the body present difficult and sometimes harsh environments for long-term material survival and performance. Coatings not only need to survive and perform appropriately, they additionally need to remain non-irritating and inert enough to be... Read More >>

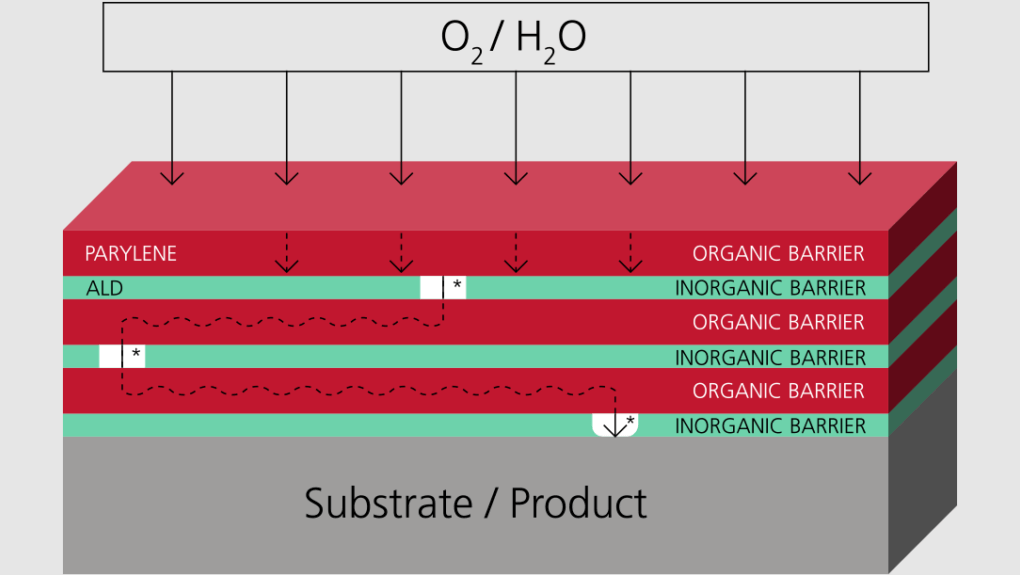

Coating Spotlight: SCS ALD+Parylene Multilayer Coatings

A newer technology at SCS, ALD+Parylene combines atomic layer deposition (ALD) coatings with Parylene to form an enhanced multilayer coating that offers increased barrier properties to protect devices in extreme environments. Multilayer coatings are stacked structures that alternate different layers of organic and inorganic thin films. ALD films can be made of numerous inorganic materials,... Read More >>