SCS Blog

Recent SCS Blogs

Solutions for 4 Key Conformal Coating Challenges

Coverage in Undesired Areas Conformal coatings cover the substrate to which they are applied. However, it is also possible for them to end up coating parts of the substrate that are not supposed to be covered. Sometimes, this happens because of inaccurate spraying. Other times, it happens because of the nature of the application —... Read More >>

Parylene Coating: Does Thicker or Thinner Coating Provide Better Performance?

Parylene (XY) conformal coatings are known and recommended because of their many beneficial performance characteristics. They provide uniform, pinhole-free protective films with excellent barrier/dielectric/insulative properties, able to conform to virtually any substrate configuration. A distinctive feature of XY is its capacity to form micron-thin coating layers. This sets it apart from liquid coatings like acrylic... Read More >>

All about the Conformal Coating Process

Acrylic, epoxy, silicone and urethane resins are applied by wet methods, including brush, dip or spray, and use either manual or robotic processes. These liquid coatings need to be cured before they can be used. Parylene is applied through a chemical vapor deposition (CVD) process that transforms the raw material for Parylene, dimer, into a... Read More >>

Coating Spotlight: SCS Polyurethane Conformal Coatings

Polyurethane conformal coatings provide excellent moisture and chemical protection and are commonly used in the electronics, defense and aerospace industries. Polyurethanes are available in single-part or two-part coatings. Two-part polyurethanes require Part A and Part B to be mixed at a predetermined ratio for proper application and curing. While there are numerous formulations available, a... Read More >>

SCS Introduces Next Generation Labcoter® 3 (PDS 2010)

SCS recently introduced its new Labcoter® 3 Parylene deposition system (PDS 2010). Designed for use in university research and R&D environments, SCS’ Labcoter delivers the capability to reliably create Parylene polymer films and coatings within your laboratory. The CE-certified system features Windows®-based software with a touchscreen monitor. Built-in data logging and reporting allow deposition process parameters,... Read More >>

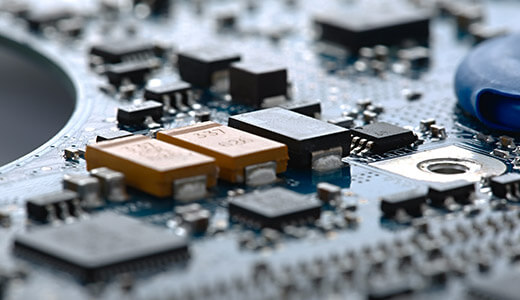

Enhancing Performance and Reliability of Automotive Electronics

High-tech electronic systems increasingly regulate functions of today’s automobile. Examples of management functions include battery management systems, engine control unit (ECU), emissions controls, fuel systems, fluid monitoring, lighting and powertrain mechanics, which are frequently comprised of miniaturized, multi-layer microelectrical mechanical systems (MEMS)/nano packages. The risk of system failure in hostile vehicular environments due to condensation,... Read More >>

Sustainable Coating Solutions

For decades, conformal coatings have enhanced the reliability of the most advanced technologies. The global shift towards sustainability has driven manufacturers to require coatings that minimize negative environmental impacts without compromising protection. Ultra-thin nanocoatings offer a highly reliable sustainable solution and unique properties to meet the specific needs of applications. A nanocoating refers to nanoscale... Read More >>

How to Keep Parylene Coating Costs Low

When designing a project, designers must be mindful of costs. In the realm of conformal coating, the focus is on securing optimal device protection at minimal expense. For projects involving Parylene coating, a thorough grasp of the 5 key elements influencing Parylene pricing is crucial. Addressing each aspect effectively will help to achieve the most... Read More >>

Protecting MEMS with Parylene Coatings: No Small Feat

As engineers continue to seek out the most powerful technologies packed into the smallest footprints possible, the use of microelectromechanical systems (MEMS) are on the rise. At the forefront of progress in miniaturization, MEMS enable small form factors without sacrificing precision and reliability. In many cases, MEMS technologies even offer an increase in performance over... Read More >>

What is the Service Life of Parylene?

Under ambient conditions (room temperature, in air) Parylene is a lifetime conformal coating. Exposure to environmental stressors like temperature, oxygen, UV-light and chemicals can degrade the lifetime, especially when two or more are present at the same time. Grattan and Bilz, reported that the useful lifetime of Parylene as a conformal coating at 25°C (room... Read More >>