<< View SCS Blog

Parylene Variant Comparison

Parylene and Its Uses

Depending on the specific use, Parylene conformal coatings can be effective in film thickness ranges of 0.1 – 50 microns, far finer than competing coating materials. Parylene’s other beneficial qualities include these multiple capabilities:

- Entirely covers any substrate to shield it from potential environmental damage

- Pinhole-free coverage/protection at thickness levels finer than other materials

- Completely homogeneous surface, providing a reliable barrier against caustic solutions, acids and water vapor

- Electrical insulation with low dielectric constancy and high-tension strain

- Thermal stability between -200°C to 450°C

- Adaptability to highly complex coating problems, including surfaces with crevices, points, sharp edges or exposed internal surfaces

In addition to consumer and industrial products, conformal coatings have a wide range of military, aerospace, medical biocompatible and implantable material uses. The most common, commercially available members of the Parylene family are Parylenes N and C, ParyFree® and Parylene HT®.

Comparing Parylene Variants

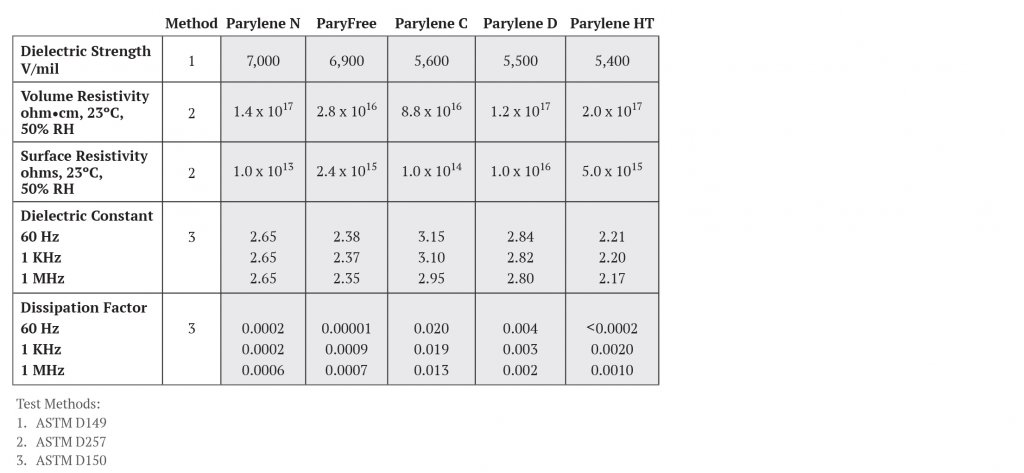

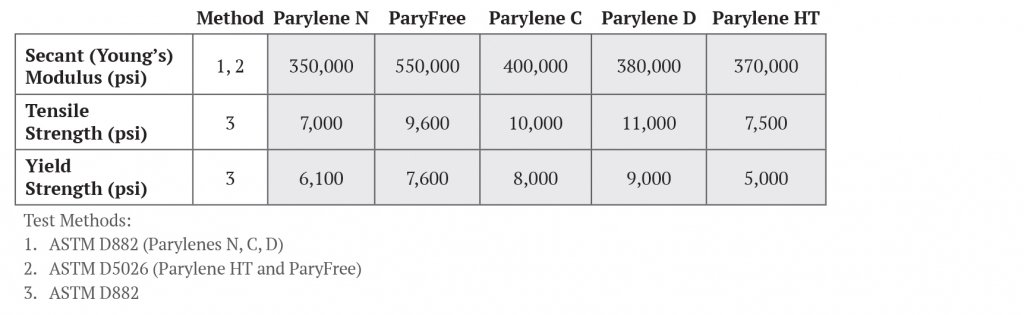

Parylene N is an entirely linear poly (para-xylylene) material with exceptional crystalline properties, the most basic of the Parylene series. It has a higher dielectric strength than Parylene C; its dielectric constant value measured in volts/mil at 1 mil, is 7000 and is independent of frequency, remaining relatively constant through frequency changes. N’s higher level molecular activity during deposition generates greater crevice penetration than Type C, making it superior for coating complex topographies.

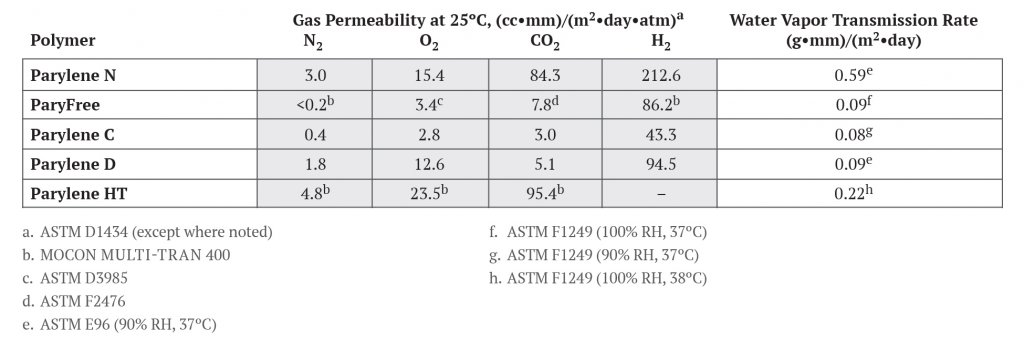

Parylene C, the most widely used, is differentiated by the single chlorination on the benzene ring, replacing one of Type N’s aromatic hydrogen atoms, and is classified as a poly-monochoro(para-xylylene). As a conformal coating, Type C offers an increased barrier property capability resulting in low chemical, moisture, and vapor permeability, making it particularly useful where protection is needed from corrosive gases.

ParyFree is a halogen-free variant developed to provide the best of breed electrical properties of Parylene N, and barrier properties of Parylene C. While this variant was specifically developed for the electronics industry, it conforms to ISO 10093 biocompatibility requirements and is used on medical devices as well.

Parylene HT, the high temperature variant, can withstand continuous exposure to 350°C as well as short-term excursions to 450°C. High temperature applications in manufacturing, electronics, exploration, automotive and other markets benefit from this elevated temperature capability.