<< View SCS Blog

How Long does Parylene Coating Last?

The stability and insulation properties of Parylene conformal coating are critical for the reliable operation of electronic devices throughout their lifetime (PCBs, MEMS, sensors, implants and so on.). The failure mechanism of the conformal coating layers is known to be due to pore formation, blistering, delamination and thinning or pinhole formation due to dielectric breakage of the coating over time [1], [2]. Therefore, the surface where the interface between the conformal coating and the substrate will be formed is of high importance. The cleanliness of this surface has a great impact on the final results of the conformal coating process and the coatings durability.

Conformal coatings provide protection against:

- Humidity/Moisture: Naval applications, salty water, bodily fluids for implants, humid areas

- Temperature: Thermal shock conditions (high-thermal gradients), hot and extreme cold climates, body (37°C)

- Chemicals: Oxidative gases, acidic, basic liquids can penetrate through protective layers inevitably leading to the device failure

- Mechanical impact: Sensors may encounter friction, compression, tensile stresses and bending under service conditions

Accelerated Parylene Lifetime Tests:

Method:

Test methods for standard electronic and electrical component parts are determined by MIL-STD-202. Testing of sealing, mechanical, chemical and thermal properties are described by MIL-STD-202 [3]. One of the most common test methods is the accelerated-lifetime soak testing. The test is conducted in saline at elevated temperatures that is relevant to the electronic part and the lifetime of Parylene conformal coatings are determined.

Literature lists a variety of applications where a combination of affecters is found together.

Oxidation and Temperature:

An extensive study on the effect of temperature and oxidation of Parylene C and N was conducted. The study used films of both Parylene N and C of thicknesses between 10 and 20 μm. Temperatures between 125°C and 200°C were used to detect the degradation of Parylene films in terms of their flexibility and mechanical properties. It was reported that the minimum useful lifetime of Parylene conformal coating at 25°C (in the absence of light) is 2,200 years for type N and 130,000 years for type C. At higher temperatures these numbers drop abruptly [4].

| Temp | 25°C | 150°C | 164°C | 175°C | 184°C | 200°C |

| Parylene N | 2,200 yr | 4.5 – 5.9 hr | 0.6 hr | 0.3 hr | 0.1 hr | 0.06 hr |

| Parylene C | 130,000 yr | 55 hr | 5.7 hr | 0.7 hr |

Parylene HT® was developed specifically for high temperature use with testing conducted at a range of times and temperatures. Results concluded that continuous service temperatures of 350°C are tolerated, with excursions for 24 hours to 450°C.

Moisture, Corrosion and Temperature:

For use in biomedical applications, the electronic chip is packaged in Parylene C (FDA approved, biocompatible) conformal coating. The package is immersed in saline solution at body temperature (37°C) for elongated times. The thicker, 9.2μm Parylene C has a long term stability. It has been shown that the Parylene can protect the metal electrode for more than 60 years. This result shows that Parylene C is an excellent structural and packaging material for biomedical applications when applied at right thickness [5].

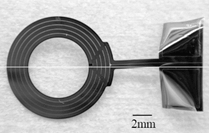

In another study, a Parylene C packaged intraocular coil for retinal prostheses were investigated for their stability at 77°C and 90°C. Again, a long term accelerated lifetime soak testing was performed in saline. In addition, a post-fabrication heat treatment was performed in a vacuum oven with N2 backfill at 200ºC, this treatment is known to lower the water permeation of Parylene thin film. The failure modes were listed as bubbles and delamination in the sample soaked at 90°C after 23 days. No delamination or major physical corrosion was reported for the sample immersed at 77ºC for over 80 days. Using these results, they predicted Parylene C stability at 37ºC for over 20 years [6].

Pressure sensors are enclosed in silicone oil to protect the circuit from water molecules or ions. In a study, researchers exploited the unusual fact that Parylene can be deposited directly on oil and its long-term lifetime of implantable pressure sensors were studied. In the study, the sensor was encapsulated in situ using Parylene C or D. Also, the study used an uncoated control sample which failed in a day at 67°C in saline. It was reported that the longest saline soaked device while maintaining adequate sensitivity and minimal offset was the one with “30,000cSt Silicone Oil + 27 μm Parylene D,” that lasted for 6 weeks at 77°C, equivalent to 21 months at 37°C. Parylene D is similar to Parylene C with a higher glass transition temperature thus can withstand moderately higher temperatures [7].

In conclusion, we can state that when the Parylene type and thickness are selected carefully, and the surface preparation is correctly done, the Parylene conformal coating is very stable and will withstand for the lifetime of the devices they protect.

References

[1] S. Minnikanti et al., “Lifetime assessment of atomic-layer-deposited Al2O3-Parylene C bilayer coating for neural interfaces using accelerated age testing and electrochemical characterization,” Acta Biomater., vol. 10, no. 2, pp. 960–967, Feb. 2014, doi: 10.1016/j.actbio.2013.10.031.

[2] A. Heid, R. von Metzen, A. Stett, and V. Bucher, “Examination of dielectric strength of thin Parylene C films under various conditions,” Curr. Dir. Biomed. Eng., vol. 2, no. 1, Jan. 2016, doi: 10.1515/cdbme-2016-0012.

[3] “MIL-STD-202 , Test Method Standard for Electronic and Electrical Component Parts.” https://www.document-center.com/standards/show/MIL-STD-202 (accessed Dec. 18, 2019).

[4] D. W. Grattan and M. Bilz, “The Thermal Aging of Parylene and the Effect of Antioxidant,” Stud. Conserv., vol. 36, no. 1, pp. 44–52, 1991, doi: 10.2307/1506451.

[5] W. Li, D. C. Rodger, E. Meng, J. D. Weiland, M. S. Humayun, and Y.-C. Tai, “Wafer-Level Parylene Packaging With Integrated RF Electronics for Wireless Retinal Prostheses,” J. Microelectromechanical Syst., vol. 19, no. 4, pp. 735–742, Aug. 2010, doi: 10.1109/JMEMS.2010.2049985.

[6] W. Li, D. C. Rodger, E. Meng, J. D. Weiland, M. S. Humayun, and Y.-C. Tai, “Flexible Parylene Packaged Intraocular Coil for Retinal Prostheses,” in 2006 International Conference on Microtechnologies in Medicine and Biology, May 2006, pp. 105–108, doi: 10.1109/MMB.2006.251502.

[7] A. M. Shapero, Y. Liu, and Y.-C. Tai, “Parylene-on-oil packaging for long-term implantable pressure sensors,” Biomed. Microdevices, vol. 18, no. 4, p. 66, Jul. 2016, doi: 10.1007/s10544-016-0089-4.