<< View SCS Blog

How Can You Validate Parylene Coverage?

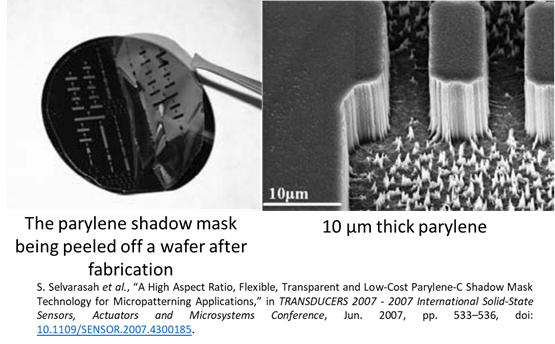

Parylene is a transparent, thin (typically applied at 0.1 to 25 microns), well adhering, pinhole and defect-free conformal coating. The coatings are uniformly applied without voids on flat surfaces and component configurations with sharp edges, points, flat surfaces, crevices or exposed internal surfaces.

Why is Parylene Difficult to Verify?

Because Parylene is transparent and forms a flawless, continuous layer, its inspection becomes difficult to the naked eye. Different types of inspection processes can be followed to verify the presence or uniformity of Parylene depending on which tools you have access to. The easiest inspection method is to examine the de-masking lines of the coated parts. A masking process is necessary to protect areas where Parylene must not be deposited. After the chemical vapor deposition process is completed, the masking material is carefully removed from the substrate without damaging the Parylene layer. Once removed, edges of the Parylene conformal coating around the areas where a masked area and a coated area meet can be observed. This inspection process can be carefully performed under light with the naked eye or by using an optical microscope for ease. Spotting the de-masking lines is a very simple way of validating the presence of Parylene.

Other validation methods include electron microscopy and Fourier-transform infrared (FTIR) characterization by which a high resolution image and a chemical fingerprint of the material, respectively, can be obtained.

REFERENCES

[1] S. Selvarasah et al., “A High Aspect Ratio, Flexible, Transparent and Low-Cost Parylene-C Shadow Mask Technology for Micropatterning Applications,” in TRANSDUCERS 2007 – 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Jun. 2007, pp. 533–536, doi: 10.1109/SENSOR.2007.4300185.