<< View SCS Blog

Conformal Coatings Protect Semiconductor Components through Harsh Environments

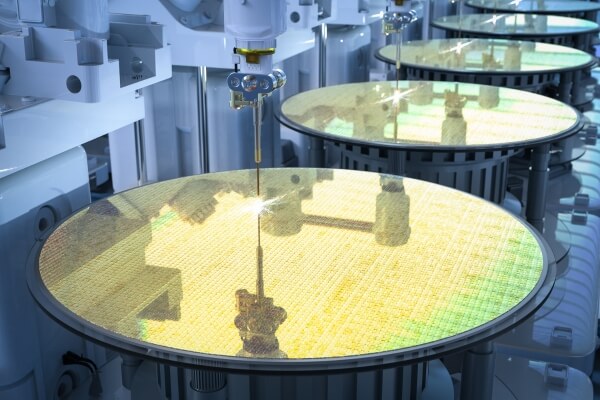

According to the Semiconductor Industry Association, the semiconductor manufacturing industry grew by 19.2% in 2024 compared to 2023, and is expected to be in excess of $1 Trillion by 20301. Evidence of this growth is that many of today’s advanced electronics contain mounted semiconductors. Before semiconductors even get to their end use, the actual semiconductor manufacturing process has many steps – several of which are highly corrosive. The harsh manufacturing environment leads to frequent part replacement in manufacturing systems which, in turn, increases operational costs.

For example, during the fabrication of wafer layers and wafer bonding, an aggressive slurry can cause corrosion of metallic equipment parts. Additionally, some polishing components also come in contact with a corrosive slurry. Due to the high cost of replacement equipment components, manufacturers benefit from a protective solution that streamlines their processes and improves profitability. Conformal coatings offer such protection against the effects of moisture and corrosive chemicals and materials while also providing electrical isolation to system components. Utilizing a conformal coating such as Parylene is proven to extend the life of parts. In one semiconductor manufacturing application, a customer stated that Parylene resulted in an estimated 300-400% increase in useful life compared to uncoated parts, significantly reducing the need for replacements.

After enduring the unforgiving manufacturing process, semiconductors are mounted onto electronic boards and PCBs and often operate in challenging environments. These electronics are commonly used outdoors, in cleaned medical devices, heavy industrial manufacturing environments and outer space. To ensure reliable performance in these demanding conditions, many semiconductor applications rely on conformal coatings.

Parylene’s corrosion barrier properties protect against aggressive slurries, harmful chemicals and corrosive gases. Additionally, Parylene can be applied at various thicknesses to optimize life expectancy of the manufacturing part or the electronics application. Parylene coatings continue to thrive in the semiconductor industry, enhancing the longevity of critical components and equipment.

To learn more about the protection conformal coatings provide to semiconductors and the equipment used to manufacture them, contact SCS.

- State of the U.S. Semiconductor Industry. (n.d.). https://www.semiconductors.org/wp-content/uploads/2024/09/SIA_State-of-Industry-Report_2024_final_091124.pdf

Global Coverage Issue 100, Fall 2024