<< View SCS Blog

What Temperature is Parylene Applied at?

Parylene (XY) conformal coatings are applied to substrate materials through a specialized vapor deposition polymerization (VDP) process that completely eliminates the liquid phase of wet coatings. In addition, no initiators or catalysts are involved in VDP, which results in truly conformal protective films. This is in stark contrast to wet coating materials such as acrylic, epoxy, silicone and urethane, typically applied via, brush, dip or spray methods. Wet during application, liquid-coated substrates requiring further drying and curing.

With Parylene VDP, a gaseous monomer uniformly encapsulates all exposed substrate surfaces; no curing is necessary. Temperature levels influence outcomes of VDP throughout the process, from sublimation through pyrolysis and cold trap procedures.

Sublimation – Dimer Transformation

In contrast to liquid coating materials, the Parylene process begins with a solid, stable granular dimer di-p-xylylene. The first phase called sublimation begins in the vaporizer section of the system, situated at opposite end of the deposition chamber, where actual coating will ultimately take place.

Regarding process temperature, dimer is heated under vacuum to levels between 120°C – 150°C, transforming it into a vapor. To optimize the process, the pressure is controlled within the system via computer control. As dimer changes from solid-to-vapor, its molecules move down the vacuum train due to the pressure differential that is generated.

Parylene Pyrolysis

Pyrolysis is essentially decomposition of a substance, in this case solid Parylene dimer, brought about by exposure to high temperatures. Consisting of two Parylene molecules, the dimer undergoes this transition at temperatures ranging between 650°C – 700°C. This level of heat causes the molecules to split apart forming the reactive, vaporous monomer p-xylylene. This resulting monomeric vapor becomes the Parylene conformal coating when it reaches the item to-be-coated in the deposition stage. Cleaved into divalent radical monomers by these high temperatures, monomer molecules:

- Enter the deposition chamber

- Make thousands of collisions with other similar vaporous molecules

- Deposit on all surfaces and form the long chain Parylene polymer on all exposed substrate surfaces within the chamber

- Cover crevices and edges

- Provide a uniform, pinhole-free coating

Cold Trap Processes

Because some monomer molecules escape the chamber without polymerization, it is necessary to protect the pump and downstream hardware from excessive polymer build-up. To do this, a cold trap process is utilized. In this downstream section of the process, temperatures are cooled between -90º and -120ºC. This process can be achieved by either liquid nitrogen or mechanical chiller cooling, which removes residual Parylene pulled through the coating chamber.

At temperatures below its freezing point, the monomer condenses as a crystalline solid. The freezing point of Parylene N registers at approximately -73°C after thermal measurement; for Parylene C, freezing point is higher, closer to -65°C.

Threshold Temperature

Common to all Parylenes, the threshold temperature is that thermal level essentially negating film deposition. Also known as the ceiling temperature, further coating deposition is negligible. Deposition rate diminishes incrementally as one nears the threshold temperature, slowing deposition until none occurs when ceiling is reached. Once physisorption begins, the p-xylylene intermediate needs to react with itself to assure polymerization.

Parylene threshold temperatures vary according to Parylene type, and each type’s molecular weight. The greater the molecular weight, the higher the threshold temperature; consult Table I:

| Parylene C | Parylene D | Parylene N | Parylene HT | |

| Threshold Temperature (°C) | 90 | 135 | 40 | 30-35 |

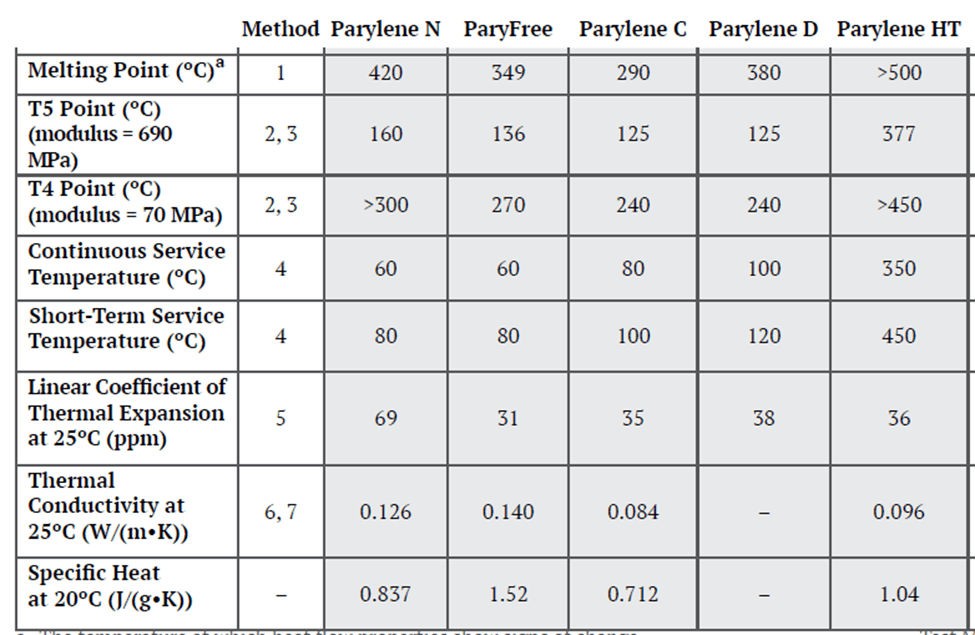

Additional Thermal Data

Further beneficial thermal properties of XY protective coatings include reliable performance through an exceptional range of temperatures. Depending on the Parylene type, XY can function at temperatures as low as -271ºC, or as great as 450ºC, representing total sustained operation within a thermal span of 721ºC.