<< View SCS Blog

How do I know 100% of My Product was Coated with Parylene?

Parylene conformal coatings are highly reliable and are highly sought after in applications across the product spectrum, ranging from military sensors to medical implants. Because Parylene coatings are colorless (transparent), thin (micro-scale) and uniformly deposited all over the target surface, they are hardly visible to the naked eye. There are methods to detect, or test, the quality of the coatings that are designated by standards (MIL-STD, ASTM) which test coatings for the encapsulation properties of Parylene depending on where they will be used. Leakage current and accelerated lifetime tests are examples of tests used to do this, both of which are conducted under different conditions (salty/saline water, elevated temperature, etc.)

The chemistry and deposition process by which Parylene coatings are generated are behind their superior conformal coating properties.

Parylene Chemistry

Polymers are formed of repeating and identical units called monomers. Thin films of polymers are formed by these monomers, building molecules via chemical bonding. The basic Parylene is known as the Poly-para-xylylene, or PPX. PPX was first observed by Michael Mojzesz Szwarc (1947) as a product of vacuum pyrolysis (thermal decomposition) of para-xylene [1]. Later, the process was improved by William Franklin Gorham (1966), who used di-para-xylylene instead of para-xylene which improved the yield to as high as 100% [2]. Today the Gorham method is being utilized for the commercial generation of Parylene conformal coatings. Gorham’s method results in linear Parylene thin films.

The Parylene Deposition Process

The chemical vapor deposition polymerization (VDP) process of Parylene takes place in three steps; sublimation, pyrolysis and deposition. The final coating is formed on the target surface (elastomer, glass, metal, paper, plastic and others). To improve the adhesion on the target surface, extra care is taken to clean the surface. Subsequently, part surfaces may also be treated using an adhesion promotion technology. Common technologies include silane (A-174) with or without the added use of plasma and the AdPro family of SCS adhesion promotion technologies. Adhesion promotion treats the surface of the components in a way to provide a high strength bond interface between the surface and the Parylene.

- Sublimation: The coating process takes place once the granular Parylene precursor is converted from solid to gas under vacuum conditions

- Pyrolysis: Above a certain temperature dimer molecules cleave into highly reactive monomer molecules. Pyrolysis of the precursor is defined as the thermal decomposition of materials at elevated temperatures in an inert atmosphere and this reaction is irreversible.

- Deposition: Monomers travel to the chamber and are deposited as a thin layer in a way to allow for a top layer to grow on them. The monomers penetrate to the smallest voids of the substrate surface, resulting in a uniform, void-free conformal coating.

Techniques and Military Standards

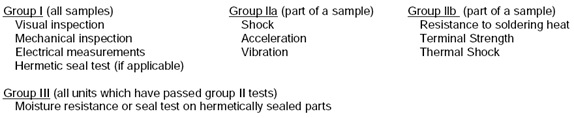

Today, standardization of any kind of a product requires set rules. Military standards, for example, are used to standardize the products for use in military applications by the Department of Defense and are commonly employed by other industries as well. Components and products used in medical applications are standardized with their own stringent requirements. The design of the product and test limits to be achieved are established with use of such standards under replicated service conditions. Test methods for standard electronic and electrical component parts are determined by MIL-STD-202 where methods for testing of seal, mechanical, chemical and thermal properties are described [4]. Parylene XY testing for use as an encapsulant for PCBs is also covered by MIL-I-46058 C [5]. In the standards a sequence of tests are specified for the parts to be mechanically and thermally stressed prior to being subjected to a moisture resistance test as follows:

Mechanical impact and failure: Sensors may encounter friction, compression, tensile stresses and bending under service conditions. Protective layers, insulators, dielectric materials used in such systems must possess mechanical properties that can withstand such mechanical forces for the longevity of applications in the field.

Temperature: (i) Abrupt changes in temperature (thermal shock) (ii) high temperatures and (iii) extreme cold can affect the functions of a protective layers used in electronic parts (i.e. dielectric layers, seals).

Humidity/Moisture: from naval operations to medical implants, exposure to salty water (saline) can damage the circuits of electronics due to corrosion and oxidation of parts.

Chemicals: Oxidative gases, acidic and basic liquids can penetrate through protective layers inevitably leading to the device failure.

Example Case and Alternative Methods

In some medical applications, implants or devices that come into contact with body fluids are required to be sealed using a conformal biocompatible coating with 100% coverage. This coating is expected to electrically isolate and protect electronic parts. Parylene is a biocompatible conformal coating, that has been demonstrated via leakage current tests to have superior encapsulation performance with results showing hermetic protection as well as long-term (>100 days) stability of the films [6]. In the same study, Parylene samples were subjected to accelerated lifetime testing (85 % relative humidity (RH) at 85 ˚C) for 20 days. Optical microscopy did not reveal any changes in the structure. Similar methodologies can be used to showcase the conformal coating and excellent protective properties of Parylene.

References

[1] M. Szwarc, “Some remarks on the di-para-xylylene molecule,” p. 4.

[2] “A New, General Synthetic Method for the Preparation of Linear Poly‐p‐xylylenes – Gorham – 1966 – Journal of Polymer Science Part A-1: Polymer Chemistry – Wiley Online Library.”

[3] J. B. Fortin and T.-M. Lu, “A Model for the Chemical Vapor Deposition of Poly(para-xylylene) (Parylene) Thin Films,” Chem. Mater., vol. 14, no. 5, pp. 1945–1949, May 2002, doi: 10.1021/cm010454a.

[4] “MIL-STD-202 , Test Method Standard for Electronic and Electrical Component Parts.” [Online]. Available: https://www.document-center.com/standards/show/MIL-STD-202. [Accessed: 18-Dec-2019].

[5] “MIL-I-46058 C INSULATING COMPOUND ELECTRICAL (FOR COATING PRINTED CIRCUIT ASSEMBLIES).” [Online]. Available: http://everyspec.com/MIL-SPECS/MIL-SPECS-MIL-I/MIL-I-46058C_11366/. [Accessed: 18-Dec-2019].

[6] “Characterization of Parylene C as an encapsulation material for implanted neural prostheses – Hassler – 2010 – Journal of Biomedical Materials Research Part B: Applied Biomaterials – Wiley Online Library.”