<< View SCS Blog

Implantable Devices and Parylene

Materials surgically-grafted or inserted onto a portion of the body are considered implantables. Although a medical implant may be composed of body tissue such as a blood vessel or tendon, many are made from artificial substances, surgically positioned within the body to improve the patient’s health by upgrading the performance of an affected organ or structure.

Parylene conformal coatings are highly biocompatible and integratable within the human body. Chemically inert, colorless and clear, their lack of pigmentation minimizes additives that can leach into the body during use, protecting from potential infection or irritation of tissue, the blood stream and internal organs.

Vapor Deposition Polymerization

Parylene coatings differ from other commercial conformal coatings. They rely on a vapor deposition polymerization (VDP) process rather than wet techniques such as dipping, spraying or brushing.

Parylene’s vapor-phase, vacuum polymerization process converts granular Parylene dimer into a gaseous form at the molecular level. With subsequent exposure to high temperatures, the vaporized dimer cleaves, or cracks, into single monomer molecules that deposit on all parts of an assembly or component and polymerize in place, forming the long-chain Parylene polymer as a durable and transparent film.

These features promote exceptional crevice/multi-layer penetration for all components and instruments as well as dependable levels of dry-film lubricity. The superior coating is uniform, pinhole-free and electrically insulative, without the liquid physics of bridging, puddling or run-off that is often common to wet conformal coatings application processes. Parylene as an ultra-thin yet resilient coating is ideal for most of the MEMS and nano technologies that are increasingly being used for medical implantables.

The Benefits of Parylene-Coated Implantables

VDP-applied Parylene coatings are used on a wide array of vacuum-stable materials and devices. Parylene coatings are biocompatible, biostable, inert, non-toxic and meet FDA and ISO 10993 compliance guidelines. These properties protect implantables through both common and extreme operating conditions typical to internal medical component usage, ensuring implanted devices perform as designed for greater periods of time.

Primary implants of this type include:

- Coronary and neural stents (small mesh tubing) that are used to treat narrow or constricted blood vessels and weak arteries, carrying blood to and from the heart and/or brain. Similar arterial/vessel stents can be applied for like purposes to stimulate blood transmission in other parts of the body.

- Neurostimulation components that treat maladies such as lower back pain, Parkinson’s, essential tremor, incontinence, depression, sleep apnea and more.

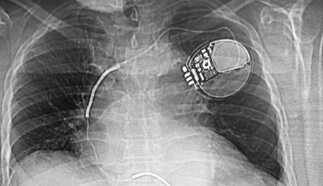

- Cardiac pacemakers and similar cardiac-assist devices (CADs) ensure regular heartbeat, preventing cardiac failure or malfunction. For instance, the delicate but complex medical electronics of such implantable CADs as cardioverter-defibrillators (ICDs) and pacemakers are protected by Parylene conformal coatings. Parylene seals these instruments from the potentially corrosive impact of body fluids circulating in the heart’s vicinity, while simultaneously eliminating the body’s exposure to electrical charges or materials leaking from the implanted CAD, further protecting the patient.

- Sensors and related hybrid-flexible sensing platforms record real-time physiological activities of organs and tissue.

- Cochlear implants, devices consisting of a microphone, signal processor, external transmitter and implanted receivers that improve patient hearing.

- MEMS and nano devices for diagnostic monitoring of patient conditions are aided by Parylene conformal coatings. Minute component and process protection assures these medical devices maintain their necessary functions throughout their specialized applications. Parylene’s dielectric properties generate an electrical barrier between MEMS’ internal electronics and electrical charges normally produced by body systems.

- Biochemical and tissue engineering devices and techniques benefit from Parylene coatings.

These devices represent just a sampling of the growing list of Parylene-protected implantable medical applications.

Conclusion

Implantables coated with Parylene have repeatedly demonstrated their reliable utility for function-focused internalized medical devices. Ultra-thin Parylene coating layers provide superior component protection, adding only minimal mass to the device, which allows components to be safely situated in difficult to access regions of the body.

The use of Parylene coatings on implantable devices is well known in the industry with more applications being developed as technologies continue to progress.