Polymer-based Parylene conformal coatings have been protecting critical components for 50 years.

Manufacturers of electronic systems and medical devices have found Parylenes conformal coatings to be an ideal solution to protect their products from moisture, dust, chemicals and other potential contaminants.

Parylene refers to a unique class of polymers that share a remarkable characteristic. Because they are applied as a gas in a room temperature chamber, the polymers deposit as an ultra-thin coating on all surfaces within the chamber. Growing in microscopic layers – one molecule at a time – Parylene coatings adhere uniformly to every corner and within every crack and crevice of an object, regardless of how small or complex its shape.

As electronics shrink in size, it is increasingly critical that protective solutions be completely conformal and lightweight. Liquid coatings, in addition to adding weight to delicate components and devices, may not provide even coverage due to the effects of gravity during their application, which can result in gaps and voids within the coatings.

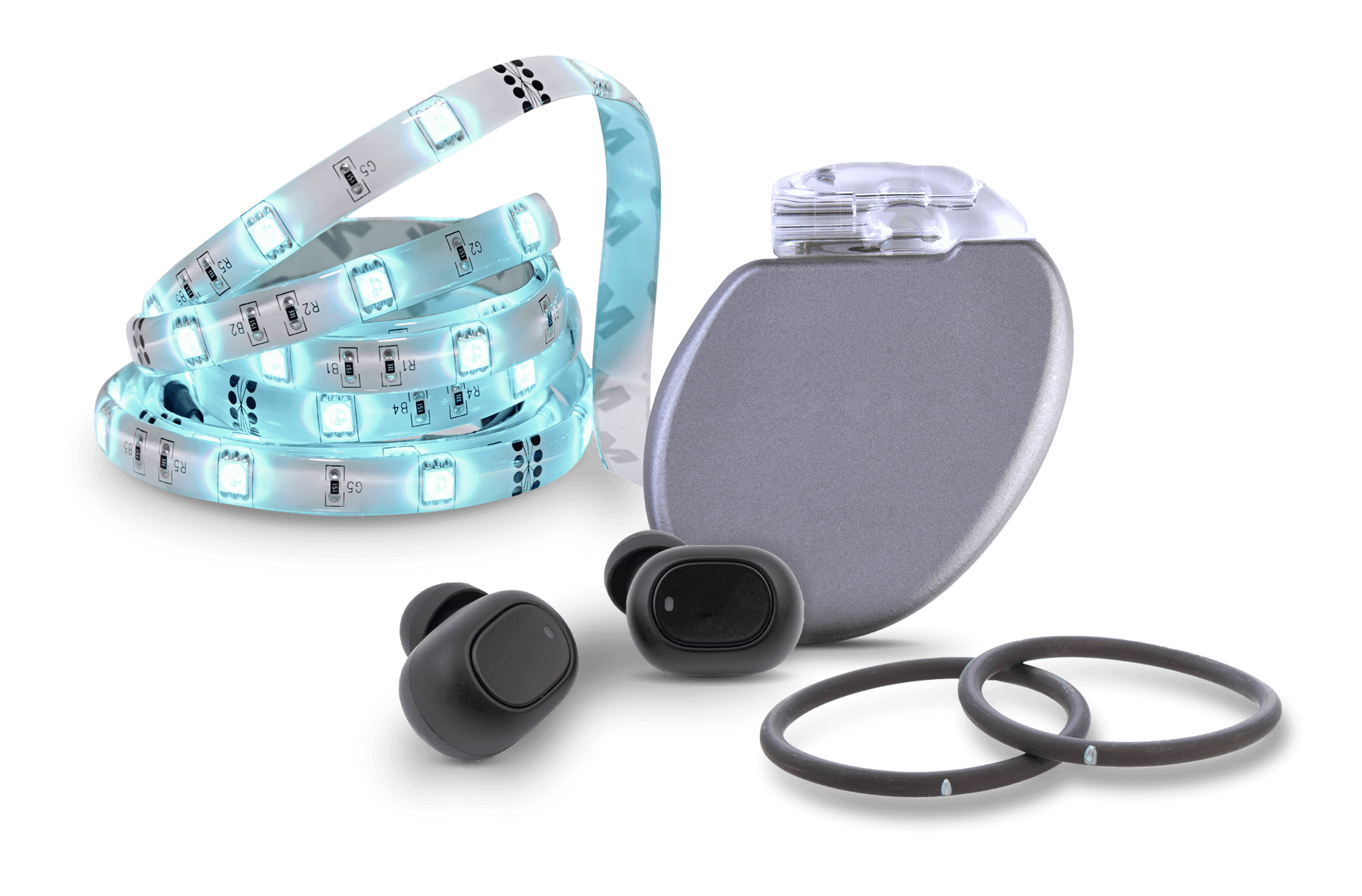

The properties and benefits of Parylene conformal coatings make them an ideal solution for protecting a wide range of applications – from the harsh environments of oil rigs and space probes to protecting medical devices and waterproofing everyday consumer electronics.

Consider how these attributes may be beneficial to your innovative technologies:

Moisture protection: Electronics protected by SCS Parylenes have passed the requirements of IPX8, demonstrating their ability to provide waterproof protection to electronic components.

Chemical protection: Parylenes are resistant to harsh materials and chemicals, including salt, fuels and concentrated acids.

Dielectric properties: SCS Parylenes have low dielectric constants and dissipation factors and high dielectric strengths, enabling electrical signal transfer without absorption or loss.

Thermal stability: Parylene HT® was specifically designed to protect components used in harsh environment applications. It is thermally stable in operating temperatures up to 350°C (long-term) and can withstand short-term exposures to 450°C.

Biocompatibility and biostability: Tested in accordance with ISO 10993 and USP Class VI, SCS Parylene coatings are biocompatible and biostable, offering protection to a wide range of medical devices.

Dry-film lubricity: Due to their low coefficients of friction, SCS Parylenes provide excellent dry film lubricity to components such as O-rings, gaskets, forming tools, syringe components, etc.

Specialty Coating Systems: An Innovative Pioneer in Parylene Science

A world leader in Parylene conformal coatings technologies and services, SCS is a direct descendant of the companies that originally developed the first Parylene variant. For 50 years, SCS scientists and engineers have developed specialized Parylene variants and adhesion technologies to provide specialized solutions for its customers.

Most recently, SCS developed ParyFree®, a halogen-free variant of Parylene, in support of the global initiatives that continue to drive toward the elimination of halogens in electronics. ParyFree coating offers manufacturers the same host of beneficial properties that they have come to expect from the Parylene family, but with improved barrier properties over traditional halogen-free variants.

With state-of-the-art facilities in 11 countries worldwide, SCS is equipped to provide high-volume, mass production coating services within a manufacturer’s production logistics.

Learn more about Parylene solutions in your industry: