<< View SCS Blog

SCS Infrared Radiation Systems Improve Curing Technology

SCS equipment is used in environments that range from university and research labs to high-volume production facilities. SCS’s proactive approach to production and quality requirements – testing, validating, documenting and processing – enables customers and their advanced technologies to meet the most challenging industry specifications and quality requirements. By staying updated on the newest trends and requirements, SCS helps its customers remain at the top of their industries. Most recently, infrared radiation (IR) curing technology has been gaining attention because of the shorter coating cure cycles it offers as well as the possibility of smaller floor space requirements when compared to convection oven curing.

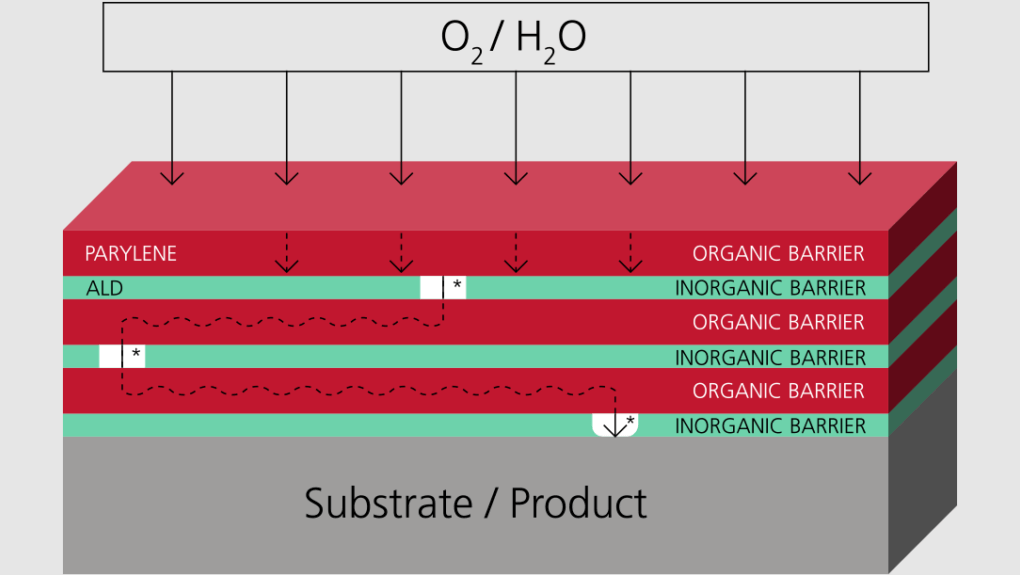

IR radiation is heat energy applied through electromagnetic wavelengths from approximately 700 nm to 1,000 mm. Using IR energy to apply heat to a substrate, instead of convection, has the advantage of eliminating hot air blowers inside the machine to circulate heated air. As a result, there are less moving parts needed to apply heat to the substrate.

The use of IR technology ensures that a substrate is heated consistently and evenly across the entire product, and thermal energy can be regulated to cure the material according to the manufacturers’ recommendations. Thermally-cured products generally involve solvents that are evaporated and carried away in the oven. When curing acrylics, for example, with single/multi-part urethanes, IR temperature helps encourage crosslinking polymerization that defines the material performance when heating is consistent across the substrate surface. IR curing ensures the coating is of optimal transparency, hardness and mechanical adhesion recommended by the coating manufacturer to support the regulatory requirements often associated with coating applications.

IR oven technology can be supplemented to include humidity, which can act as a primary or secondary curing mechanism. A moisture-rich environment ensures that the full cure is accelerated and continues after the product has exited the curing system. Humidity-enhanced curing provides a visible and mechanical advantage over ambient air curing systems.

Understanding how important IR curing technologies are to its customers, SCS developed two new systems – the SCS PrecisionCure TC (IR) and SCS PrecisionHeat – to further advance curing and coating technologies. Both systems feature a heating profile database, independently-controlled heating zones, pin-change-edge handling, left-to-right conveyor travel, powered conveyor width adjust, 4″ top and bottom passthrough heights, double-walled heat enclosure, optical inlet/outlet sensors, side access panels, automatic runaway heater shutdown, exhaust interlock sensor, Windows®-based software with a touchscreen monitor and SMEMA interface. Additionally, each system can operate as a stand-alone machine or can fully integrate with SCS PrecisionCoat selective conformal and dispense systems.

The PrecisionCure TC (IR) thermal curing system provides customers with the reliability and efficiency needed throughout the curing process. Available with two or four heating zones, each zone is heated with 12 ceramic heaters for even zone heating. The number of zones are a function of time and capacity to best meet customer needs as well as facility space requirements. Four-zone ovens are ideal for heat curing of materials following their application and when the oven is equipped with optional ultrasonic humidification. Two-zone ovens are best for materials that do not need heat application for an extended periods of time.

IR temperature provides very precise control compared to convection heat. Additional unique features of the PrecisionCure TC (IR) include a board position indicator on Human-Machine Interface (HMI), standard powered conveyor width and a simple machine design for specific product-curing parameters. When integrated with a PrecisionCoat system, the oven also provides production reports, and it is cost competitive vs. other curing options.

The PrecisionCure TC (IR)’s optional humidity control incorporates an ultrasonic spray nozzle and humidity sensor to elevate the tunnel’s relative humidity, decreasing the cure time for certain types of materials with a secondary moisture curing mechanism. It also offers a host of options including a tower light, temperature profiling and analysis, IR board temperature monitoring, barcode reader, right-to-left conveyor travel and automated programmable width for consistent run/run processing.

An additional new product from SCS is the PrecisionHeat IR thermal preheating system, which is ideal for heating substrates prior to dispensing underfill materials. The two-zone system features 12 ceramic heaters per zone for even heating. The final zone is equipped with an IR temperature probe, providing users with real-time temperature feedback and control over the heating cycle.

The system is unique because it heats and controls the energy introduced to the entire product rather than applying heat to only a single area during the application process. Additionally, the PrecisionHeat offers a stage and soaking temperature in which temperature-sensitive materials are applied. Preheating the entire assembly helps prevent over-heating of components and helps users control the coefficient of thermal expansion (CTE), which is often critical to monitor on complex assemblies.

The PrecisionHeat is designed for continuous operation, requiring minimal downtime for maintenance. Available options for this system include a tower light, temperature profiling and analysis, barcode reader, right-to-left conveyor travel and automated programmable width.

As an experienced coating innovation leader, SCS focuses on providing the most updated conformal coating, dispensing, cure and testing systems to meet customers’ needs. For coating materials that require humidity and thermal or IR cure technologies, SCS offers two IR thermal systems that are robust, reliable and ensure that users’ processes are as efficient as possible. The SCS PrecisionCure TC (IR) thermal curing system provides the reliability and efficiency needed throughout the curing process while the SCS PrecisionHeat IR thermal preheating system is ideal for heating substrates prior to dispensing underfill materials.

For more information, visit scsequip.com or contact Hans Bok at 508.997.4136 or hbok@scscoatings.com.

Global Coverage Issue 92, Summer 2022