Spray Coating and Dispense Systems

PrecisionCoat VI

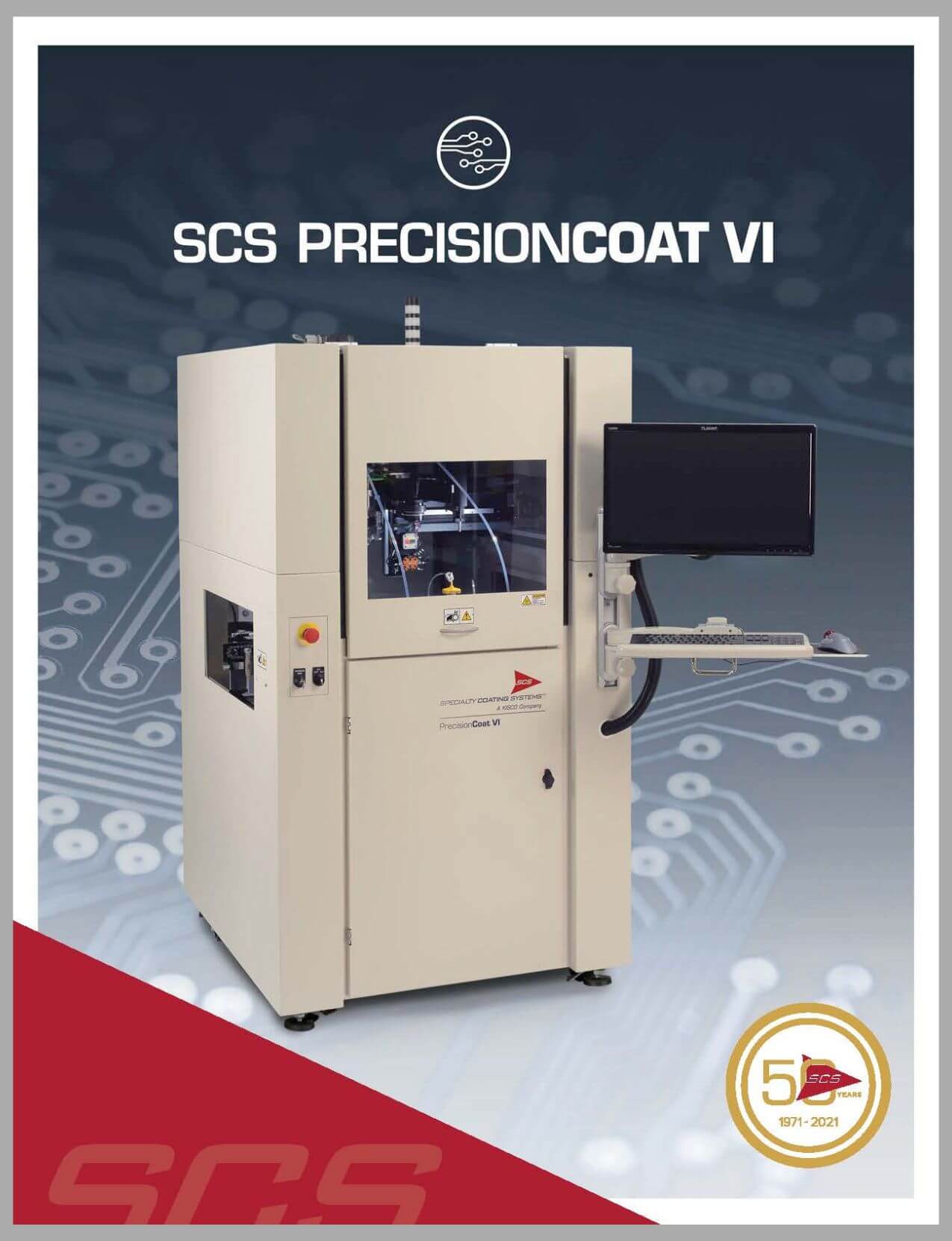

The SCS PrecisionCoat VI provides more than a dependable layer of protection; it's a total system solution that ensures accuracy, repeatability and high throughput for a wide range of automated material applications.

Product Information

The SCS PrecisionCoat VI selective conformal coating and dispense system is a fully programmable, multi-purpose system that offers unparalleled programming for efficiency in automated material applications. SCS customers rely on the PrecisionCoat to precisely apply a wide range of materials, including 100% solids, solvent-based and water-based coatings. Building upon the outstanding reliability and precision of its predecessor, this robust and highly flexible platform offers manufacturers the unmatched efficiency and accuracy they have come to expect for conformal coating, dispensing and/or potting applications.

The SCS PrecisionCoat VI selective conformal coating and dispense system is a fully programmable, multi-purpose system that offers unparalleled programming for efficiency in automated material applications. SCS customers rely on the PrecisionCoat to precisely apply a wide range of materials, including 100% solids, solvent-based and water-based coatings. Building upon the outstanding reliability and precision of its predecessor, this robust and highly flexible platform offers manufacturers the unmatched efficiency and accuracy they have come to expect for conformal coating, dispensing and/or potting applications.

The PrecisionCoat’s standard configuration applies materials via a direct-drive, three-axis system with accuracy of 0.001 inches; fully programmable fourth and fifth axes can also be added to most systems for tilt and rotate functionality. The PrecisionCoat VI, which is controlled by proprietary Windows®-based software, provides users with unparalleled offline programming capabilities and file backup.

Optional features such as programmable tilt and rotate, Automatic Quick Change (AQC) with up to 8 configurable valves, fiducial recognition, needle calibration, programmable atomization and laser-height mapping are available to maximize system efficiency and meet any production requirement. The system can also be tied to an integrated manufacturing system by means of SMEMA transfer standards. The PrecisionCoat VI has spray booth door and exhaust interlocks for safety.

Conformal Coating Applications: The PrecisionCoat VI offers numerous spray and dispense valves that apply a wide range of conformal coating materials such as silicones, acrylics, urethanes, epoxies and other materials. With a combination of spray and dispense valves, along with 3-5 axes of movement, boards can be selectively coated without the need for time-consuming masking and de-masking.

Dispense Applications: Multi-valve technologies on the PrecisionCoat VI enable the application of dots, lines, fills and glob-tops, all with a single system. The following valves are available, and often interchangeable, on SCS PrecisionCoat systems: two-part mixing dispense, dot dispense, jetting technology, flow coat and low- to medium-speed solder paste dispense. For maximum flexibility, atomizing and non-atomizing spray valves can also be integrated into a dispensing platform.

Potting Applications: The PrecisionCoat VI potting platform dispenses silicones, epoxies, urethanes, etc. to seal, stabilize and/or protect applications from shock, vibration, moisture or corrosion. An automated potting process allows industrial electronics, lighting, military and avionics manufacturers to precisely control the volume of material dispensed, increasing efficiency and decreasing waste. The PrecisionCoat VI can be configured with one head or multiple heads and can dispense one or two-part materials.

From printed circuit boards to custom semiconductor assemblies and MEMS, a wide range of industries have found value in the SCS PrecisionCoat and the automated coating and dispensing technologies it offers. Further adding value to a production line, SCS PrecisionCoat VI systems mate seamlessly with SCS Cure Systems for inline UV and thermal curing. For more information, contact SCS.

Key Features and Benefits

- High accuracy and repeatability

- Servo motor position control

- Windows®-based software control with user-friendly interface

- Ease of programming

- Profile sharing between multiple coating systems; including previous PrecisionCoat models

- SCS designed valves

- Multiple dispensing and mixing solutions

- Interior LED lighting

- SMEMA transfer protocols

- CFX compatible

- Safety interlocks

- Batteryless absolute encoders

Optional Features

- 5 axes programmable tilt and rotate

- Automatic Quick Change (AQC) with up to 8 configurable valves

- Vision system

- Coating flow meter

- Needle calibration system

- Programmable valve spacing

- Programmable spray pressure

- Programmable pot pressure

- Programmable syringe pressure

- Laser height mapping

- Valve on/off during continuous motion

For more information on the SCS PrecisionCoat VI, download our product brochure or contact SCS.

Specifications

Click on the Playlist icon in the upper left corner of the player to select the PrecisionCoat demo video you would like to view or click on the Play icon to view them all.