DIP COATING SYSTEMS

PL-3201

The SCS PL-3201 tabletop Dip Coater has all the features found in our P-3201 Dip Coater, plus a number of optional features that bring added performance and functionality to the process of dip coating.

Product Information

For lab and short-run operations, the SCS PL-3201 Dip Coater is an ideal choice. This tabletop unit features a 14″ x 18″ coating tank and offers the same level of precision and reliability found with our SCS floor unit. The SCS PL-3201 gives you the ability to coat printed circuit boards with urethane, epoxy, silicone and acrylic coatings, as well as photoresists and solder mask materials, all with a high level of efficiency. This compact unit also incorporates an air-over-oil cylinder mechanism to safely move circuit assemblies in and out of the coating solution.

System Features

- Powered by compressed air cylinder for smooth, explosion-proof operation

- Adjustable immerse and lift speeds, 1-24 inches/minute

- Dip assembly supports multiple boards per dip cycle

- Removable tank for fast, easy coating changes

- Independently adjustable immersion and withdrawal rates

- Stainless steel tank cover minimizes vapor loss

- Accurate immersion control eliminates masking above dip line

- Meets National Fire Class1, Group D explosion-proof standards for Division 1 environment

Optional Features

- Circulation pump and overflow dam

- Dip dwell (0-30 seconds)

- Tank air blanket and flow meter

- PTFE coated tank

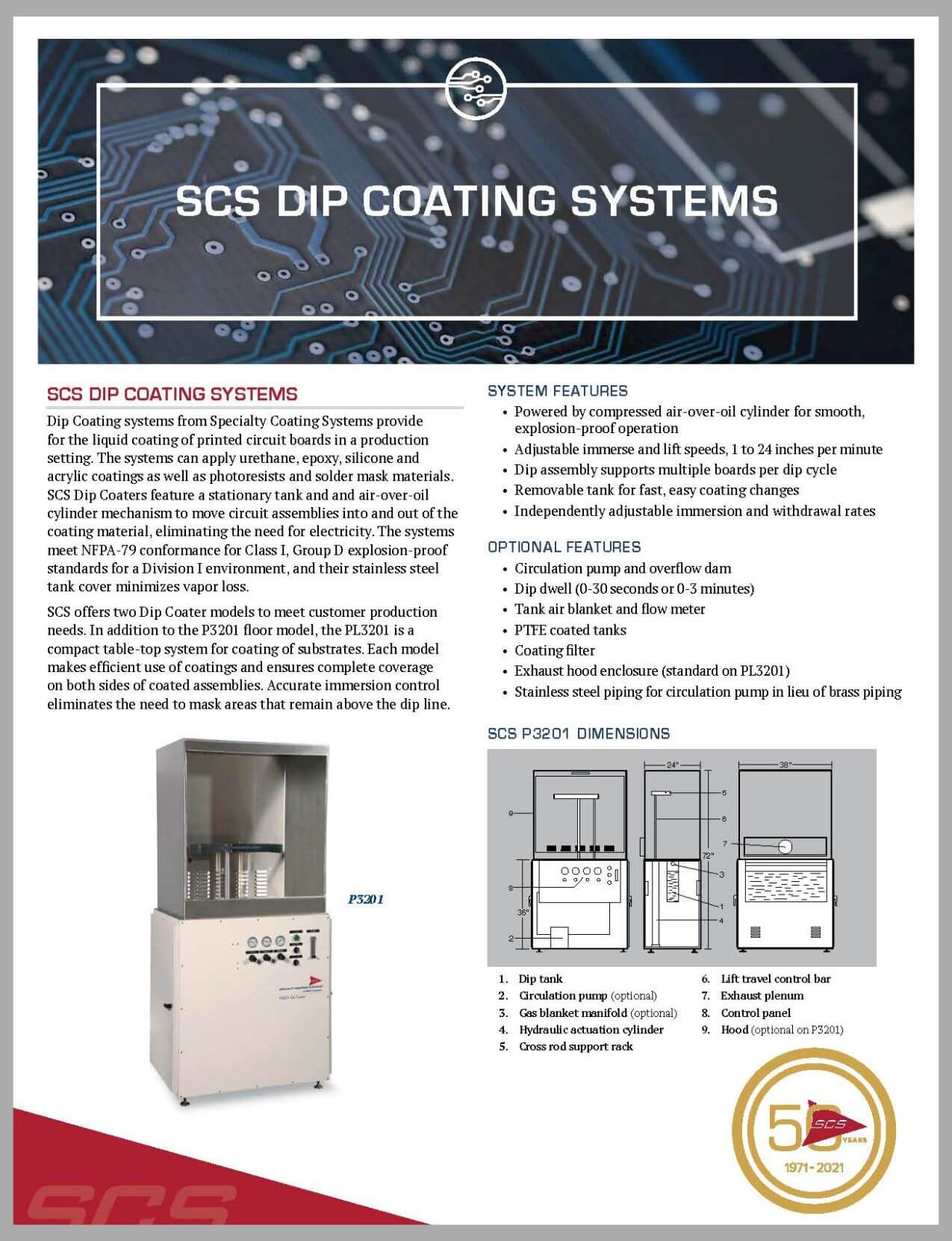

Specifications

Unit size

28.5 in. W x 19 in. D x 37 in. H (72.4 cm x 48.2 cm x 94 cm)

Tank size

18 in. L x 4 in. W x 14 in. D (45.72 cm x 10.16 cm x 35.56 cm)

Tank drain

1/2 in. (1.27 cm)

Immersion capacity

Up to 8 in. (20.3 cm), with 6 in. (15.2 cm) freeboard

Immersion rate

1 to 24 in./min (2.54 x 61 cm/min)

Withdrawal rate

1 to 24 in./min (2.54 x 61 cm/min)

Dip Depth

Adjustable by sensor position

Actuation

Compressed air at 15 cfm/80 psi (8.49 m3/hr./5.5 bars), oil and moisture free

Exhaust

200 cfm (340 = m3/hr.)

SCS Dip Coating Systems

The SCS PL3201 is a compact, precision dip coating system for table-top coating of printed circuit boards. This portable system can apply urethane, epoxy, silicone and acrylic coatings, as well as photoresists and solder mask materials.